Trends in food processing industry

With an impressive growth rate of 10-12% per year, the food processing industry not only shows great potential but also contributes to putting Vietnam on the world food map. However, the problem of raw material quality, value chain linkage, green transformation pressure and increasingly strict requirements of major markets are posing many challenges.

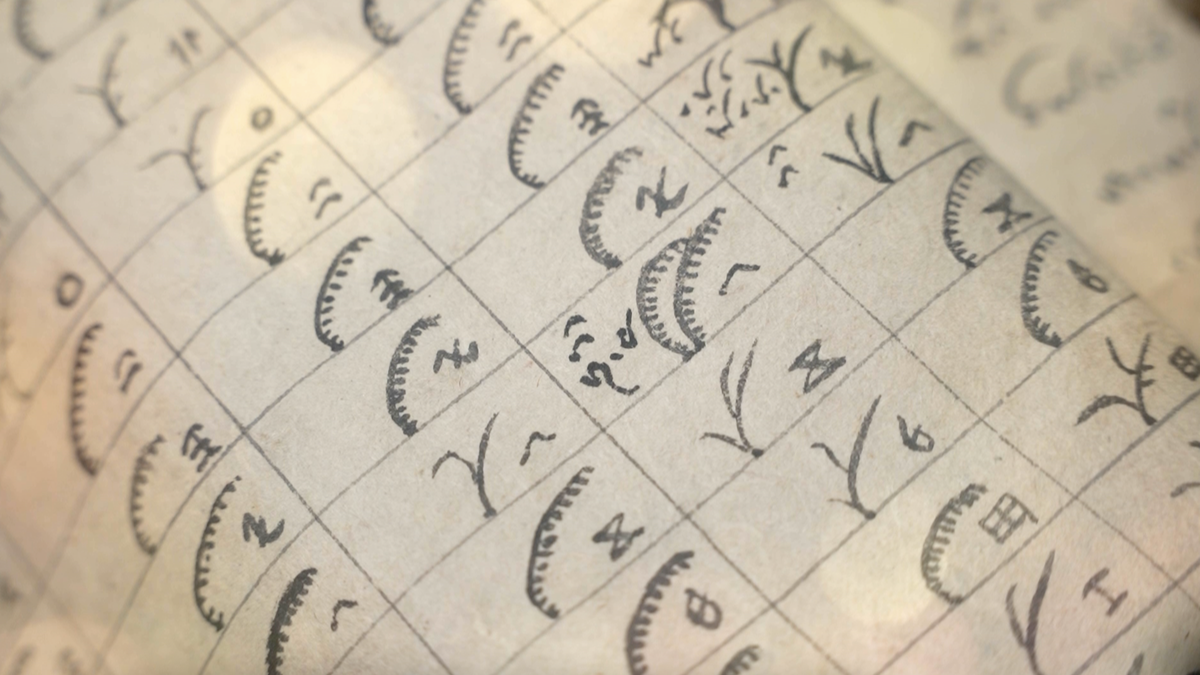

According to Go Global (European-American Market Department, Ministry of Industry and Trade ), 70-85% of Vietnam's agricultural products are exported in raw form or with low processing content. The situation of good harvest but low price is still common, production is fragmented, and the quality of agricultural products is not uniform.

Processing technology is still limited, not synchronized, designs are not attractive, production costs are high, leading to the fact that Vietnamese food products in general still do not have a competitive advantage in the international market. In addition, the incomplete and ineffective logistics system is always a challenge for many businesses.

Faced with increasing pressure, businesses in the food processing industry in Vietnam are making efforts to increase investment in technology, automation and improve management capacity.

Following the Government's macro orientation on green transformation and sustainable, smart industrial development, Nestlé Vietnam continues to demonstrate its long-term commitment by announcing a new investment of 75 million USD (nearly 1,900 billion VND) to expand the Nestlé Tri An factory (Dong Nai), in celebration of its 30th anniversary in Vietnam.

This is not only one of the most modern coffee processing factories of Nestlé Group, but also a place that creates added value for Vietnamese agricultural products, putting Vietnamese coffee beans on the world coffee map .

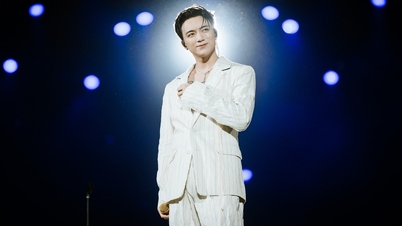

The new investment has increased the total capital invested in the Tri An factory to 175 million USD, bringing Nestlé Vietnam's total investment capital to 904 million USD (nearly 20,200 billion VND) (Photo: Nestlé Vietnam).

Towards high-tech factories

Sharing about the new investment capital in Vietnam, Mr. Binu Jacob, General Director of Nestlé Vietnam, said: "The additional investment focuses on two main goals: upgrading processing technology, especially freeze-drying technology, which requires high technology, and expanding capacity, adding new production lines, including a line for coffee capsules, a product line that is growing strongly in many markets.

However, the special point of this investment is not only focused on hardware, but will also increase resources for software, including human capital development, technological innovation, digital transformation, green growth and contribute to the comprehensive development of Nestlé in Vietnam."

In the context of the entire food and processing industry being under pressure to digitalize, Nestlé Tri An factory with the largest scale and most modern technology in the region has completely automated its operating processes. All are controlled from the central room via the computer system.

This is also the factory producing decaffeinated coffee beans (decaf coffee) applying modern technology in Vietnam and is the second largest decaffeinated coffee bean factory of the group.

Continuing the journey of sustainable development

Along with technological modernization, Nestlé Vietnam identifies human resources as the core factor determining the success of any transformation. Nestlé Tri An Factory is implementing high-tech human resource training programs, developing internal management and leadership capacity, and promoting a culture of innovation throughout the enterprise.

The operations team at Tri An not only masters advanced technologies but is also equipped with strategic thinking skills and the flexibility to adapt to change. In addition, Nestlé also focuses on building a safe, transparent working environment and promoting gender equality, which are important factors in retaining and developing talent.

In addition to human resources, investment in sustainable development is considered a core principle in Nestlé’s operational strategy. Since 2015, all Nestlé Vietnam factories, including Tri An factory, have achieved the goal of zero solid waste landfill. This means that Nestlé factories have recycled 100% of production waste and no longer discharge waste to landfills.

Particularly at the Tri An factory, the renewable energy and water circulation system has been deployed synchronously, along with the group's global Net Zero carbon emission reduction goals.

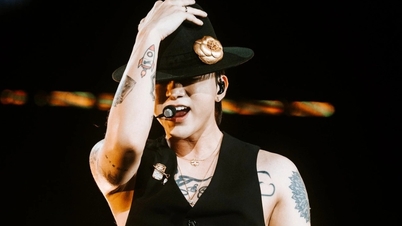

Nestlé Vietnam identifies people as the core factor determining the success of every transformation (Photo: Nestlé Vietnam).

In the next phase, Nestlé Tri An will continue to be a "launching pad" for regenerative agriculture initiatives, closely linking the factory and raw material areas.

With a solid foundation from three strategic pillars: digital transformation, human development, sustainable growth, Nestlé Tri An factory is becoming a model of modern industry in Vietnam. Not only a production project, this is also a way for businesses to make practical contributions to the country's rising era.

Source: https://dantri.com.vn/kinh-doanh/nestle-tiep-tuc-dong-hanh-cung-viet-nam-trong-ky-nguyen-phat-trien-ben-vung-20250526190203044.htm

Comment (0)