Amazon is building robots that can do everything from transporting shirts and bottles of soap to stacking packages. Amazon executives hope these robots will save the company from having to hire hundreds of thousands of workers in the coming years.

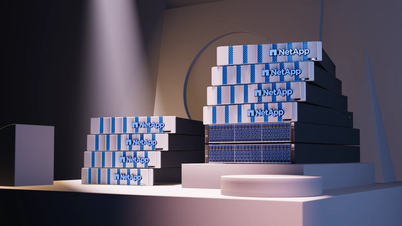

Amazon's Sparrow robotic arm system. (Source: New York Times)

How did Amazon get started with robots?

In 2012, Amazon acquired robot maker Kiva, which makes short, round robots that can lift stacks of goods and deliver them to workers.

Since then, Amazon has categorized all of its operations into six categories of automation: movement, manipulation, sorting, storage, recognition, and packaging. “We want to have world- class capabilities in each of those categories,” Tye Brady, head of Amazon Robotics, said in an interview last fall.

Amazon's approach addresses a core dilemma in robotics development: whether to create a robot that can do many things but is difficult to develop, or to create a robot that focuses on one skill but is more likely to succeed.

Amazon has chosen the latter: Hercules is used to move heavy carts, Pegasus is used to transport and sort packaged orders. There are also a series of robotic arms, Robin and Sparrow, used to manipulate items and packages.

Robots pick up and collect empty baskets for workers. (Photo: Telegraph)

What robots is Amazon using?

A few years ago, Amazon began rethinking how its main warehouses operate. The biggest change was an overhaul of how Amazon stores and ships goods.

In the old system, Amazon stored products in fabric-fronted towers of cabinets; workers reached into the cabinets and searched for the desired product.

In the new system, called Sequoia, the storage bins are replaced with plastic bins that automatically slide in and out of frames. Products can move around in these bins. And thanks to computer vision technology, Amazon can look at the bins from above to identify the products. Then, robotic arms pick up the products using suction cups.

The Sparrow robot arm will look into the product bin, select the desired product and place it in another bin. (Photo: Tech Crunch)

At Amazon’s most advanced warehouse in Shreveport, Louisiana, employees only need to touch products at a few steps, such as taking them out of shipping boxes and placing them in bins. Then, a Sparrow robot arm looks into the bin, selects the desired product and places it in another bin.

A robotic arm named Robin places the packed packages on a small robot named Pegasus, which then sends the packages down specific chutes depending on where they’re going. Below that chute, a tall, muscular robotic arm named Cardinal picks up the sealed boxes and places them on a cart.

A turtle-like robot named Proteus will slide under those carts and autonomously carry the goods to the docks. As it moves around workers, Proteus's lights form a smile.

In addition, Amazon has other innovations such as packaging robots, air blowers, and labeling machines capable of applying 3,000 stickers per hour.

Amazon's Pegasus robot system specializes in moving heavy objects. (Source: New York Times)

According to the New York Times, Amazon - the second largest e-commerce corporation in the US - is planning to replace more than 500,000 jobs with robots, marking a new turning point in the company's operating strategy.

Amazon’s US workforce has more than tripled since 2018, reaching nearly 1.2 million people. However, the company’s automation team predicts that by 2027, Amazon may not have to hire more than 160,000 additional workers, saving about $0.30 per item picked, packed and delivered.

In centers designed for super-fast delivery, Amazon is developing warehouses that are nearly human-free, aiming to automate 75% of operations, executives say.

Source: https://vtcnews.vn/nhung-robots-cuop-viec-cua-500-000-nhan-su-tai-amazon-ar972710.html

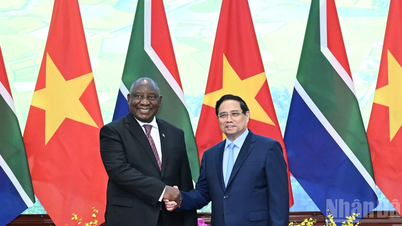

![[Photo] Prime Minister Pham Minh Chinh meets with South African President Matamela Cyril Ramaphosa](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/10/23/1761226081024_dsc-9845-jpg.webp)

![[Photo] President Luong Cuong holds talks with South African President Matamela Cyril Ramaphosa](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/10/23/1761221878741_ndo_br_1-8416-jpg.webp)

![[Photo] Prime Minister Pham Minh Chinh chairs meeting on railway projects](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/10/23/1761206277171_dsc-9703-jpg.webp)

![[INFOGRAPHIC] vivo Pad5e, 12 inch 144Hz Tablet, Snapdragon 8s Gen 3 chip](https://vphoto.vietnam.vn/thumb/402x226/vietnam/resource/IMAGE/2025/10/23/1761226679125_thumb-vivo-pad5e-jpg.webp)

Comment (0)