BHG - Holding in hand the Ha Giang newspaper with its beautiful design, printing colors, and rich content, not everyone knows that its success is due to the efforts of the Editorial Board, each reporter, editor, and artist, but also the contribution of the "Printing House" workers.

April 13, 2025, marks the 61-year journey of building and growing Ha Giang Newspaper. Throughout that journey, generations of leaders, cadres, reporters, and editors of Ha Giang Newspaper have constantly overcome difficulties, innovated, and created; performed well the assigned political tasks. Always accompanying Ha Giang Newspaper, contributing to the innovation of the newspaper's quality, meeting the information and entertainment needs of readers; serving well the political tasks of the locality - that is Ha Giang Printing Joint Stock Company, which many people often call with the intimate name "Printing House".

|

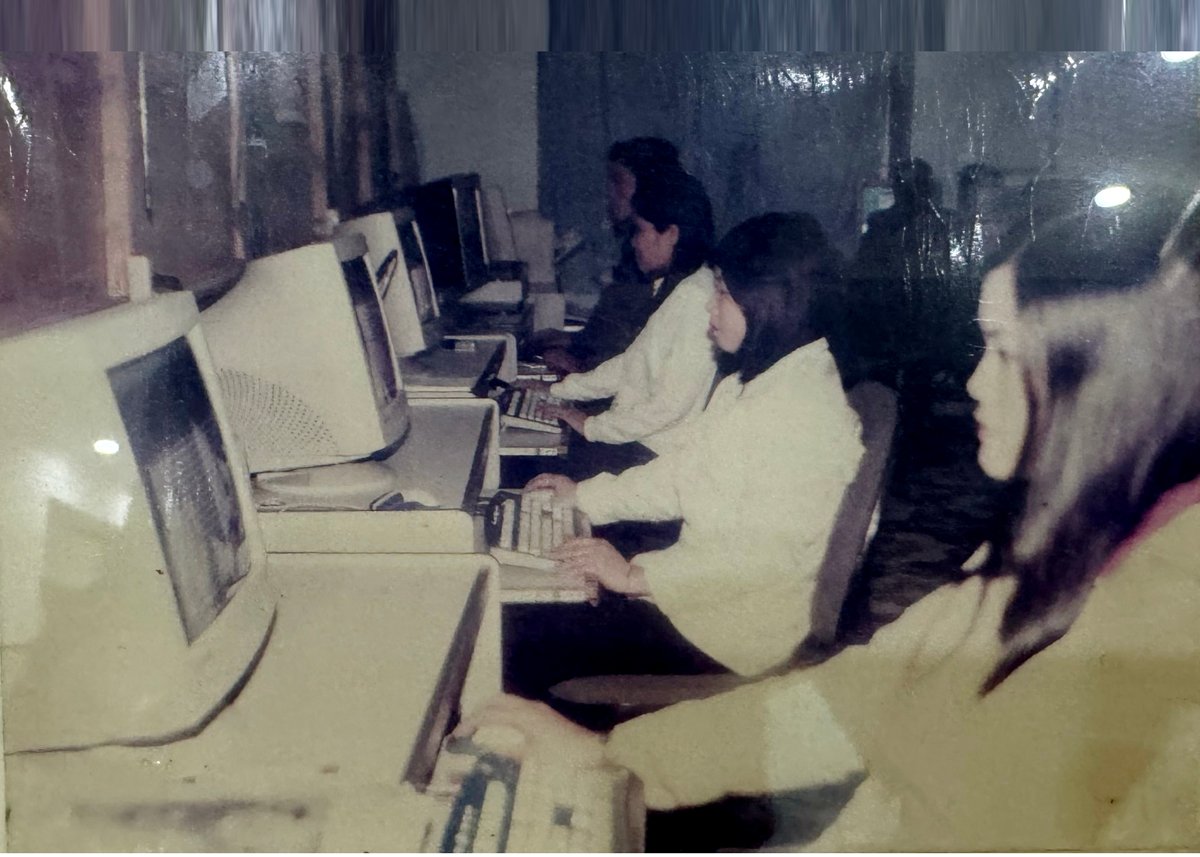

| Electronic publishing technicians at the editorial office in 2003. Photo: DOCUMENT |

Newspaper printing technology has been innovated according to the development trend, but there was a time when, in order for a newspaper to reach the readers, it had to go through the “lead typesetting” stage, a job that now only remains in the memories of the previous generation of journalists. Before the technology of electronic printing, the first step in newspaper printing technology was lead typesetting. When the draft of news, articles, and photos was edited and typed, the artist then drew the layout. After the Editorial Board approved the mock-up, it would be sent to the Printing House.

At the Printing House at that time, the letters, according to different fonts and sizes for printing newspapers, were all cast from lead metal. The letters were contained in trays, each tray divided into small boxes containing a separate letter in order a, b, c. The "Typesetters" held a small mold containing the letters, the mold was as wide as a newspaper column, and with the other hand picked up each letter and arranged it according to the content of the manuscript, but arranged it in reverse, reading from the right side. In addition to remembering the positions of the boxes, the typesetters also had to have the skill of reading letters in reverse. When the letters were arranged to fill a newspaper column, the mold was carefully rolled up with a string, then the printer rolled the ink roller onto the letters and printed a copy on newspaper to check against the original. If there were any wrong letters, the wrong letters had to be taken out and replaced with the correct ones. When rearranging, they had to calculate and discuss with the Newspaper Editorial Board and artists to cut or add to fit the frame. Once the font has been adjusted to the standard layout, everything is fixed with a tightly bolted iron frame (the size of the frame is equal to the size of a newspaper page) and then put into the printing machine for printing.

After finishing printing a newspaper issue, the typesetter must accurately rearrange the letters from the printer into the boxes in the original tray to have the letters arranged for the next page. The step of taking the letters from the printer and putting each letter back into the old box also requires absolute precision, because if the letters are not placed in the correct box, the next typesetter will have errors. The job of typesetting a newspaper is not hard, but it requires the worker to be meticulous, patient, proficient, and quick-handed and quick-eyed. In difficult times, ingenuity emerges, each person must have a creative way of counting letters, calculating column division, and presenting the newspaper page. They are so proficient that sometimes they do not need to look at the boxes containing the letters to get the correct letters to arrange.

To print an issue, it is not enough to arrange the type according to the set layout, but there are changes because many times, the typesetting for the newspaper page has been completed and it is ready to be printed, but due to the sudden propaganda requirements of the province, the news and articles have to be changed, so the typesetters remove the news or articles to arrange new ones, working all night to print on time. There are times when the power goes out while they are typesetting, so they have to turn on flashlights to arrange the type. There are also many days when they have to work through noon and night to print the newspaper on time. Two issues a week, then three issues, not to mention other publications of the province, it is so hard, but the typesetters and the printing machine department are always enthusiastic about their work. They are like diligent bees, meticulous, passionate, and quiet with their work so that the newspaper has no errors, is published on time, and reaches readers as quickly as possible.

One of the “Typesetters” of that time is now the Deputy Manager of the Prepress Workshop of Ha Giang Printing Joint Stock Company, that is Ms. Vuong Thi Hong. Her mother, Ms. Mai Thi Som, has retired for more than 20 years, and has also been a “Typesetter” for many years. She has passed on a lot of experience of the profession to her colleagues and Ms. Hong. Recalling a difficult time, Ms. Vuong Thi Hong said: “Those days of diligently arranging lead type, my hands and feet were always dirty and black but I was still happy. Many days, waiting for the news from Ha Giang Newspaper to be transferred, to ensure the early publication of the newspaper, the on-duty team of the “Printing House” together with the leaders, editors and layout artists of the Newspaper had to work until 3-4 am to finish. The issues followed one another, hard work and difficulties, but the typesetters, the people working at the “Printing House” were always passionate and attached to the profession”. The hard times are over, now, making newspapers with electronic technology, all on computers, is faster, more convenient, and more accurate.

Mr. Ha Van Trang, Chairman of the Board of Directors of Ha Giang Printing Joint Stock Company, said: Over the years, the Company has continuously invested in equipment, modernized the Offset printing system, applied technology to production, and innovated in production to increasingly improve the capacity and quality of publications to meet the increasingly high demands of the market. No longer having to do many steps like in the old printing machine, today's printers only need to operate on the control panel (PC table) to produce colorful, high-quality products. Time is saved, and labor productivity is also much higher than before. Compared to the old printing system that took 5 hours to complete the finished product, this system only takes 50% of the time to complete the entire issue. Along with printing Ha Giang Newspaper, the printing process of other publications is increasingly innovative and creative.

Typesetting technology no longer exists, the workers of that time have retired, but for Ha Giang Printing Joint Stock Company and Ha Giang Newspaper, “lead typesetting” is still a memory.

Dang Phuong Hoa

Source: https://baohagiang.vn/van-hoa/202504/sap-chu-chi-mot-thoi-de-nho-5ac6699/

![[Photo] General Secretary To Lam receives Australian Ambassador to Vietnam Gillian Bird](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/6/26/ce86495a92b4465181604bfb79f257de)

![[Photo] Candidates take the first graduation exam with the new Literature topic](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/6/26/dfded9e317554c25a3e26defe672ebb7)

Comment (0)