Dak Nong aluminum industry is developing strongly, but to make a breakthrough, it is necessary to synchronously solve the problems of traffic infrastructure, energy and training of high-tech human resources to meet the requirements of modern and sustainable production.

.jpg)

.png)

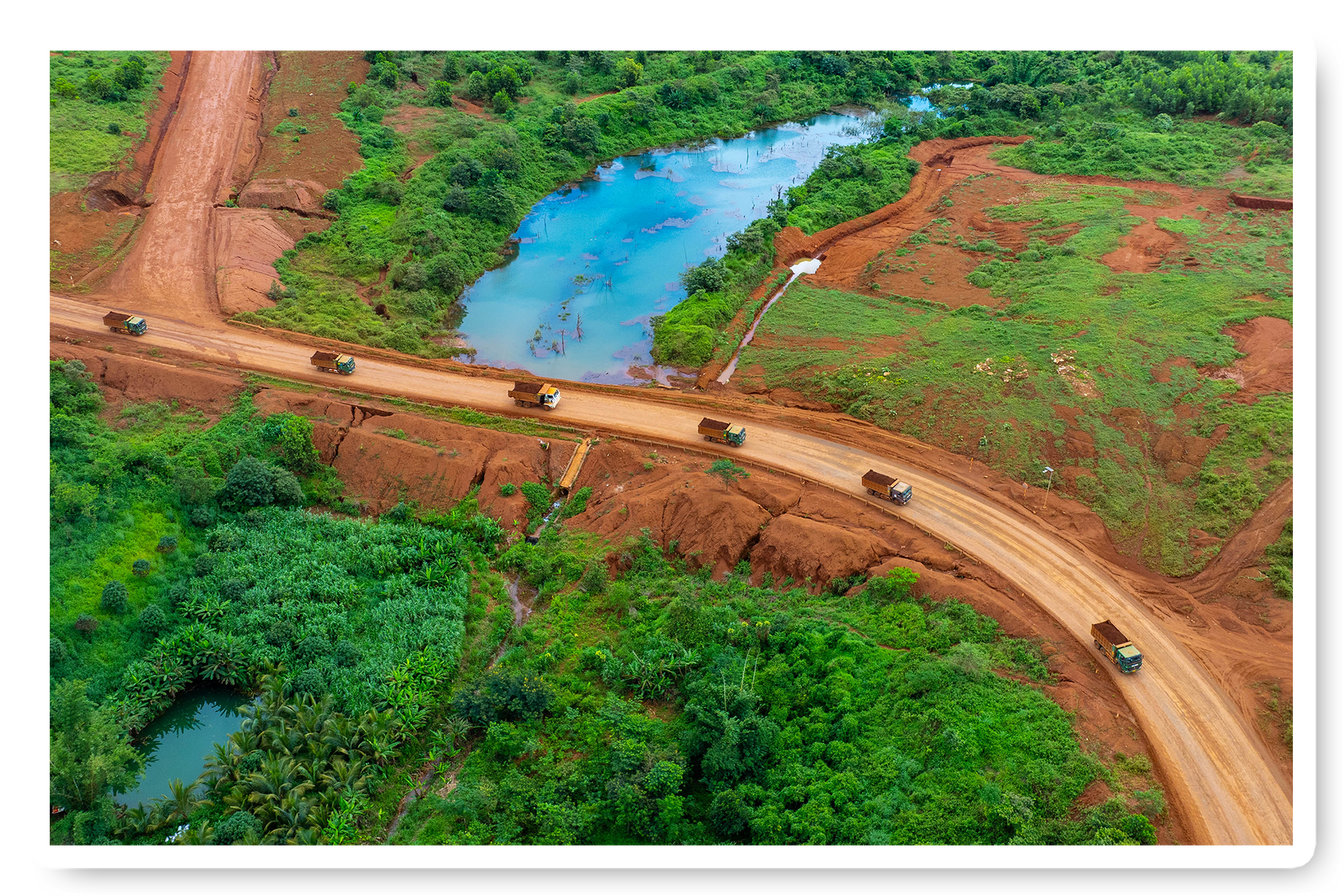

Vietnam National Coal and Mineral Industries Group (TKV) has invested in and put into operation two bauxite mining and alumina production projects in the Central Highlands. Currently, bauxite ore from the mines to the processing plant is transported by specialized vehicles, using internal roads in the mine. Bauxite concentrate (after washing) is brought to the alumina production plant by conveyor belt, under cover.

Aluminum products at Tan Rai Aluminum Factory and Nhan Co Aluminum Factory Project are both exported. After processing, aluminum products will be transported by trucks by road from the factory to Go Dau port ( Dong Nai province). In the opposite direction, these trucks will carry coal from the port to the factories.

According to TKV, each aluminum factory transports goods back and forth about 23,000 times a year. The transport vehicles have large loads, travel on steep, narrow mountain roads and through residential areas, so they easily cause congestion, posing a potential risk to traffic safety.

In its plan, around 2030, TKV will increase its capacity to 2 million tons per factory. In Lam Dong, TKV will build an aluminum electrolysis plant with a capacity of 0.5 million tons/year. In Dak Nong, TKV will invest in the Dak Nong 2 bauxite - aluminum - aluminum complex with a capacity of 2 million tons of aluminum and 0.5 million tons of aluminum/year.

It is expected that after the investment, TKV can produce a maximum output of 6 million tons of aluminum and 1 million tons of aluminum per year. In Dak Nong alone, the designed output can reach 4 million tons of aluminum and 0.5 million tons of aluminum. The demand for transporting goods will increase more than 6 times compared to the present, putting great pressure on the transportation system.

.jpg)

Not only TKV, many domestic corporations have submitted documents to invest in, exploit and process bauxite in Dak Nong with large total registered capital. According to the Central planning, Dak Nong will build 4 more factories to exploit and process bauxite with a total investment of not less than 1 billion USD for each project. This is a great opportunity for Dak Nong to break through and develop commensurate with its potential and advantages.

However, the transportation network of the Central Highlands region still has many limitations. In Dak Nong, the only mode of transportation is road. This is a major bottleneck for socio-economic development in general and the expansion of production projects along the aluminum value chain in particular.

________________

.png)

Standing Vice Chairman of Dak Nong Provincial People's Committee Le Trong Yen said that due to limited resources, investment in transport infrastructure in Dak Nong is not synchronous. To promote advantages and promote development aspirations, Dak Nong identifies the special importance of investment in transport infrastructure development. Resolution of the 12th Provincial Party Congress (term 2020 - 2025) continues to identify transport infrastructure development as one of the three breakthroughs of the province.

Recently, Dak Nong has actively coordinated with Binh Phuoc province to promote the implementation of the Gia Nghia - Chon Thanh Expressway Project. This project was approved by the National Assembly in June 2024.

At the end of April 2025, Binh Phuoc and Dak Nong provinces simultaneously organized the groundbreaking ceremony for the component project passing through the area, belonging to the expressway project. It is expected that the expressway will be invested and basically completed in 2026, put into operation and use in 2027. In another direction, Lam Dong and Dak Nong provinces have worked and agreed to invest in local connecting traffic routes. In particular, the two provinces are promoting the upgrading and expansion of National Highway 28 and the construction of the dynamic traffic route Gia Nghia (Dak Nong) - Bao Lam (Lam Dong).

Currently, the provinces are promoting the survey of the expressway connecting Phan Thiet City (Binh Thuan) - Da Lat City (Lam Dong) - Gia Nghia City (Dak Nong). The three provinces will meet and agree on the most reasonable investment plan to propose the Central Government to add this expressway to the planning.

If the roads are upgraded and the highway connecting the three provinces is formed, Dak Nong will have an additional connecting axis to the East, towards the sea.

The transportation route for the aluminum production chain in particular and goods in general from Dak Nong will have more options when moving through Lam Dong, connecting to Ho Chi Minh City via the Dau Giay - Lien Khuong expressway which is being promoted for investment.

Standing Vice Chairman of Dak Nong Provincial People's Committee Le Trong Yen emphasized: The expressway is expected to open a new chapter for Dak Nong and the Central Highlands. These roads will contribute to removing bottlenecks, unlocking resources, creating a breakthrough for the aluminum industry in particular and the socio-economy in general.

The bauxite - alumina - aluminum industry is on the rise, leading to the need for high-quality human resources to ensure long-term stability.

Not only stopping at production, the factory always focuses on building high-quality human resources. From equipment operators to automation and digital technology, all are invested, trained thoroughly and continuously updated with knowledge.

Every year, Dak Nong Aluminum Company – TKV always allocates certain resources for training. In 2025 alone, the company will spend more than 7.9 billion VND on training and professional development for officers, employees and workers in the entire unit.

The company's leaders said that this policy is completely consistent with the company's development needs in the context of increasing investment, applying synchronous mechanization and automation in the production and business process. Training is developed equally in all three main labor groups in the company, including: senior and middle-level managers; experts in engineering, technology, and management; technical workers in key industries. These are the three indispensable pillars for the company's development in the new period.

In addition to Nhan Co Alumina Plant, Dak Nong has planned to build 4 alumina plant projects to process bauxite ore at mine clusters 2, 3, 4, 5. These are: Dak Nong 2 Alumina Plant Project (Dak Glong); Dak Nong 3 Alumina Plant Project (Dak Song); Dak Nong 4 Alumina Plant Project (Tuy Duc); Dak Nong 5 Alumina Plant Project (Dak Glong).

.png)

Dak Nong has now agreed on the investment policy for bauxite ore processing plant complex projects in mine clusters 2, 3, 4, 5, ensuring compliance with Decision 866/QD-TTg, dated July 18, 2023 of the Prime Minister approving the Planning for exploration, exploitation, processing and use of minerals for the period 2021 - 2030, with a vision to 2050, in accordance with legal regulations.

The projects that are seeking investment approval all focus on deep processing of bauxite minerals and must produce at least alumina products. The technology for alumina processing, aluminum smelting and post-aluminum products of the projects are all advanced, with modern equipment.

Similarly, the Aluminum Electrolysis Plant of Tran Hong Quan Metallurgy Co., Ltd. is expected to produce the first batch of aluminum in the second quarter of 2026. When operational, the project will contribute about 900 million USD to the province's GDP each year. And especially create about 950 direct jobs.

Investing in large numbers of bauxite - alumina - aluminum complexes in Dak Nong is requiring a large, high-quality labor force to meet the operational needs of the factories.

Not out of the trend, Vietnam National Coal - Mineral Industries Group (TKV) has now determined the strategy for developing the aluminum industry. In the period of 2021 - 2030, TKV aims to produce 1.4 - 2.8 million tons of aluminum per year and produce the first ton of aluminum ingots in 2030. In the next phase, TKV's aluminum products can reach 4 - 6 million tons/year. To achieve this goal, human resources are always identified as a key factor by the unit.

Mr. Nguyen Tien Manh, Deputy General Director of TKV, informed that the unit has been developing many reform policies in recruitment, training, and international cooperation. Accordingly, the group will cooperate in training with foreign countries to improve the quality of human resources; in which, focusing on training and recruiting high-quality resources with foreign language proficiency, knowledge, and practical experience.

The Group continues to send cadres at all levels to study and visit foreign mines with advanced technology and modern corporate governance systems. The Group organizes training programs, exchanges experts, and exchanges operational management experiences with international organizations...

The aluminum industry is on the way to breakthrough. The problem of human resources also needs to be solved with a long-term, systematic and synchronous strategy. Training must go one step ahead, because only when people master technology, this industry can truly become a driving force for sustainable economic development.

_______________

The environment in the aluminum production chain is well controlled and is expected to change significantly with the application of more modern technology.

The Nhan Co Alumina Plant in Nhan Co Commune, Dak R'lap District, was required to conduct a thorough environmental impact assessment right from the start of its operation in 2010. In 2017, the plant installed an automatic emission monitoring system and continuously updated technical measures to minimize environmental risks. The wastewater collection, noise reduction and dust treatment systems were also upgraded, helping to keep air and wastewater quality within acceptable limits.

.jpg)

During its operation, the Nhan Co Alumina Plant has faced a number of environmental problems. Notably, in September 2017, treated wastewater from the reservoir leaked due to prolonged heavy rain, although it was promptly treated. At other times, dust emissions to the surrounding area due to peak production activities were also recorded and quickly resolved.

According to Dak Nong Aluminum Company - TKV, since then, the factory has not had any environmental incidents. Environmental protection work during the bauxite mining and aluminum production process at Nhan Co Aluminum Factory has been well controlled.

During the period 2017 - 2024, TKV spent about 100 billion VND on environmental protection at Nhan Co Alumina Factory. The entire area of more than 204 hectares after bauxite mining for alumina production in Dak R'lap has been replanted with acacia trees according to the approved environmental improvement and restoration project.

At the end of 2023, the Ministry of Agriculture and Environment granted an environmental license to Nhan Co Alumina Factory. According to this license, the factory is responsible for operating waste treatment facilities in accordance with the process. The factory must ensure that the quality of exhaust gas and wastewater meets standards before discharging into the environment; take measures to minimize noise and vibration and handle incidents if pollution exceeds the threshold.

Leaders of the Department of Agriculture and Environment of Dak Nong said that the production and operation of Nhan Co Alumina Factory in the past time have ensured environmental regulations. The operation process over the past years has not had any environmental incidents, which has been highly appreciated by the people and local authorities.

“The operation of Nhan Co Alumina Plant always complies with technical and technological processes, ensuring safety for people and equipment. The quality of exhaust gas, wastewater, noise, dust, etc. are all below the committed threshold,” said the leader of the Dak Nong Department of Agriculture and Environment.

In recent times, Dak Nong Aluminum Company - TKV has implemented a series of measures, initiatives and projects to protect the environment. The experimental solutions have been put forward to ensure that the production environment is always safe according to the law.

Recently, Dak Nong Aluminum Company - TKV has successfully tested planting acacia on the area of sludge discharged after washing. On a land area of about 6 hectares after bauxite mining, Dak Nong Aluminum Company has tested covering the surface with a layer of sludge after washing, then planting acacia on top.

Through monitoring by Dak Nong Aluminum Company - TKV, the entire planted acacia area is growing and developing well. This is an important premise for the plan to return the washed sludge back to the bauxite mine to create a flat surface, especially when TKV is planning to expand, upgrade and invest in more bauxite - alumina - aluminum production complexes.

A very notable new point is that TKV is testing the technology of discharging dry red mud in the alumina production process. This is an advanced solution, bringing environmental, economic and technical benefits compared to the traditional wet discharge method, currently used at two TKV alumina factories.

According to TKV representative, red mud is a liquid waste (with high pH) generated in the process of producing alumina from bauxite ore. During the alumina production process, the red mud is pumped into specialized reservoirs, lined with waterproof tarpaulins to prevent alkaline osmosis into groundwater.

.jpg)

Wet red mud disposal technology is expensive because it requires large areas to build storage tanks. Waste management in storage tanks also needs to be strict to avoid sludge overflowing into the environment during heavy rains.

Meanwhile, the red mud dry disposal technology is carried out by concentrating the mud into a paste with a high solid content. The dry red mud waste will be transported to the landfill to be stacked in layers, allowing land savings and improving the stability of the landfill.

Since 2025, TKV has begun testing dry waste technology at the Tan Rai alumina complex (Lam Dong). Initially, the application of this technology has brought many benefits in terms of saving land resources, environmental safety and reducing total investment costs.

TKV representative said: According to its orientation, TKV is planning to upgrade the two Tan Rai and Nhan Co alumina complexes to a capacity of 2 million tons of alumina/year. TKV will invest in a new alumina project with a capacity of 2 million tons/year in Dak Nong before 2030. With many positive signals about the environment, we will expand and apply red mud dry disposal technology to all of our expansion projects and new investments.

Performed by: Thuy Duong, Le Dung, Le Phuoc, Nguyen Luong

Presented by: Phong Vu

(The article uses some documentary images)

Source: https://baodaknong.vn/thu-phu-nhom-va-doi-hoi-giao-thong-nhan-luc-moi-truong-250882.html

![[Photo] General Secretary To Lam attends the 95th Anniversary of the Party Central Office's Traditional Day](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/10/18/1760784671836_a1-bnd-4476-1940-jpg.webp)

![[Photo] Collecting waste, sowing green seeds](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/10/18/1760786475497_ndo_br_1-jpg.webp)

![[Photo] Closing ceremony of the 18th Congress of Hanoi Party Committee](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/10/17/1760704850107_ndo_br_1-jpg.webp)

Comment (0)