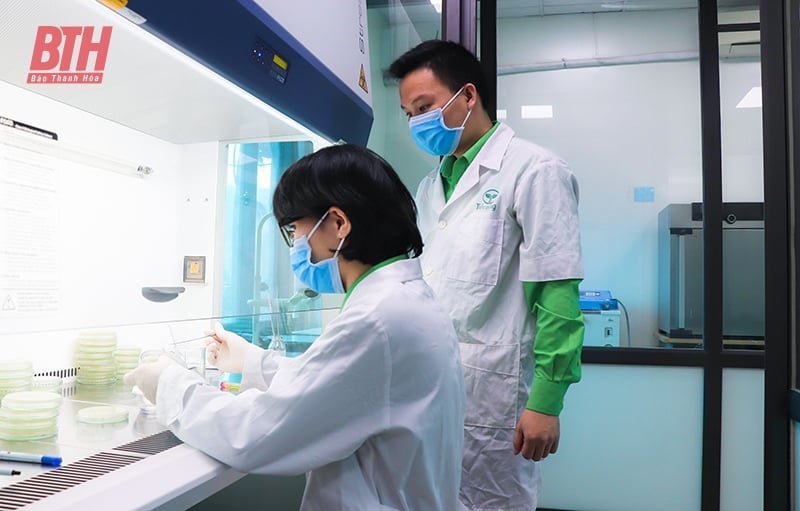

Tien Nong Center for Science and Technology Development Research is continuing to develop organic fertilizer lines, applying nanotechnology to minimize soil and water pollution in agricultural cultivation.

On the vast sugarcane fields in Thanh Hoa, clean sugarcane is grown by selected varieties, irrigated with water-saving systems, without using toxic chemicals. The journey from the field to the final product is strictly controlled according to ISO, GlobalG.AP, HACC standards... which are strictly controlled by Lam Son Sugarcane Joint Stock Company (Lasuco). The processing factories operate according to a circular economic model: utilizing bagasse as biomass fuel, molasses as food additives and even producing organic fertilizer to serve the raw material area.

In particular, Lam Son sugarcane raw material area is approaching to become the first agricultural area in Vietnam to be able to sell carbon credits in the international market. This is the result of a cooperation project between Lasuco and two partners from Japan, aiming to build a low-emission sugarcane farming model. The project focuses on sustainable farming methods such as not burning sugarcane leaves after harvest, using organic fertilizers instead of chemical fertilizers and extending the sugarcane root cycle to increase carbon accumulation in the soil. At the same time, the MRV (measurement - reporting - verification) monitoring system is deployed, integrating satellite technology to continuously monitor the raw material area. This is not only an important step in the journey to realize the NetZero goal but also opens a new direction for sustainable agriculture in Vietnam.

Lasuco Deputy General Director Le Van Quang emphasized: “With the vision of becoming the leading green agricultural and food corporation in Vietnam and reaching out to the international market, Lasuco identifies that the corporate brand is also associated with the “green” brand and is an invaluable asset, the foundation for all long-term development strategies. We are promoting the application of digital transformation and technology in management from raw material areas to production according to the circular economic model, helping to increase efficiency, reduce emissions and create clean products that meet international standards. Along with that, the enterprise promotes product lines with Vietnamese identity such as natural rock sugar, kumquat sugarcane juice, protein-rich rice milk, rice products... to meet the increasing demand of demanding markets such as Japan, EU, Korea and the United States.

If Lasuco has made its mark in agriculture, then in the heavy industry sector - which is easily labeled as "polluting" - VAS Nghi Son Group has proven the opposite. With the motto of developing "green steel for a sustainable future", VAS's steel rolling mill in Nghi Son Economic Zone has invested thoroughly in technology and environmental management. The highlight of this model is the use of steel scrap instead of mined iron ore, which helps recycle resources and reduce CO2 emissions. The factory is also equipped with a closed-loop exhaust gas treatment system and a heat recovery system to save electricity and reduce negative impacts on the surrounding environment. According to a representative of VAS Nghi Son: "The story of green steel does not stop at modern equipment, but also in production culture. We train workers to practice clean production, strictly control each stage to achieve the goal of comprehensive "greening" from input to output."

May 888 Company (Quang Xuong) uses clean energy in production, meeting the "green" standards of high-end markets such as the EU and Japan.

Currently, VAS Nghi Son steel products have achieved certifications such as ISO 14001 on environmental management, and are exported to many markets with high requirements for “clean” standards such as Korea, Australia and the Middle East. Not only creating environmentally friendly products, VAS is also one of the few enterprises that build an annual “sustainable development report”, publicly disclosing energy consumption, greenhouse gas emissions and reduction roadmap.

In addition to the two typical models mentioned above, Thanh Hoa also recorded many enterprises actively making green transformation. That is Tien Nong Agricultural and Industrial Joint Stock Company develops organic fertilizer lines, microbial fertilizers and applies nanotechnology to reduce soil and water pollution in agricultural cultivation. Haca Agricultural Cooperative (Nghi Son) combines clean production with consumption through digital platforms, reducing costs and emissions from transportation, creating a brand of environmentally friendly agricultural products. Xanh SM - VinFast 's electric taxi service contributes to changing consumer habits, moving towards green transportation and reducing pollution in large cities such as Thanh Hoa City and Bim Son Town. May 888 Company (Quang Xuong) invests in a closed wastewater treatment system, clean energy, aiming at the green standards of high-end export markets such as the EU and Japan.

In practice, green branding is not only a choice, but also an inevitable path. But for businesses that change, it is also the shortest path to trust and conquer the modern market. Each product line, each production process, each development strategy that has been "greened" has gradually shaped a new look for product brands and business brands.

However, to spread the value of green brands, it is necessary to have stronger participation from the government in supporting businesses to access green credit, clean technology, as well as promoting “green” standard products to domestic and foreign markets. In particular, “green consumption” and responsible consumption are important factors contributing to promoting this production trend.

Article and photos: Tung Lam

Source: https://baothanhhoa.vn/thuong-hieu-xanh-huong-di-tat-yeu-trong-thi-truong-hien-dai-249468.htm

![[Photo] Dan Mountain Ginseng, a precious gift from nature to Kinh Bac land](/_next/image?url=https%3A%2F%2Fvphoto.vietnam.vn%2Fthumb%2F1200x675%2Fvietnam%2Fresource%2FIMAGE%2F2025%2F11%2F30%2F1764493588163_ndo_br_anh-longform-jpg.webp&w=3840&q=75)

Comment (0)