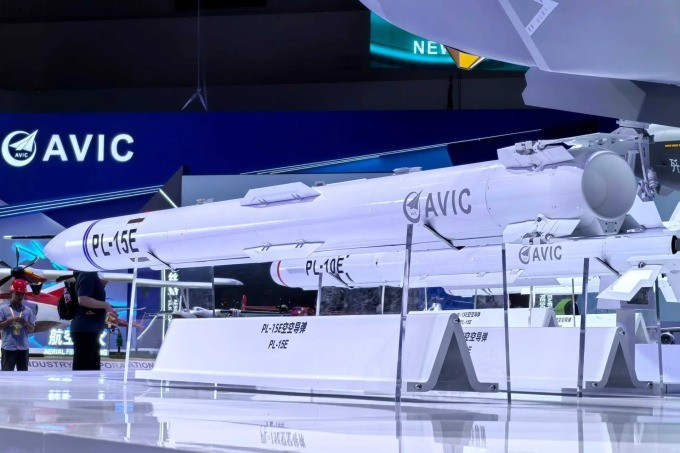

Indian news agency IANS reported on May 9 that on May 7, in Kamahi Devi village in Hoshiarpur district, Punjab state, northern India, Indian people found "trophy" in the field, which was a PL-15E long-range air-to-air missile of the Pakistani army, made in China, found in an almost intact state.

Images of the scene show that most of the missile's body is intact, with all its fins and fins intact. The missile's nose has been broken off, with what is believed to be the guidance system lying nearby.

The missile has the serial number P15E12203039 and the words "China Electronics Technology Group Corporation, 55th Institute" can be clearly seen on the missile body. The PL-15E missile, according to its design, if it does not hit the target, will self-destruct after running out of fuel; but due to a malfunction in the self-destruct mechanism, the missile accidentally "landed safely" in an Indian field.

The acquisition of a relatively intact PL-15E missile is a unique opportunity for India to study the missile's technical and tactical features as well as its limitations, and from there, find technical and tactical solutions to deal with similar weapons from the enemy. Even Indian Defense Minister Singh made a bold promise: "Give me three years to build an Indian version of the PL-15"?

The question is, does India have the capability to copy China's missile? First of all, the active electronically scanned array (AESA) radar of the missile seeker is the most difficult part for India to copy, the easiest part to copy is the warhead. The engine casing is marked "made in 2015" - maybe this missile was made in China 10 years ago.

To protect the missile's secrecy, China has created a special alloy mixed in silicon carbide composite material, which will create false signals during X-ray scanning. Can the laboratory of India's Defence Research and Development Organisation (DRDO) analyze the materials used to make the PL-15 missile's homing radar?

While China’s PL-15 missile production line, as revealed by CCTV, can produce this type of missile at a rate of 30 missiles/day, India still has to import 60% of the Tejas fighter jet components. So can India produce the three main components of the missile: AESA radar, dual-pulse engine and anti-jamming data link?

The components used to make AESA radars are gallium nitride (GaN T/R), which requires wafers with 99.9999% purity; but India's most advanced semiconductor factories are still using the 28-nanometer process and their wafer quality is less than one-third of China's.

The fuel formula used for the dual pulse engine can be called a “chemical code”. While the fuel stability issue of India’s Astra rocket remains unsolved to date and remains without a solution after three laboratory explosions.

In terms of data link systems, the Russian, French, Israeli and American weapons currently in combat service in the Indian Army, like the “unintelligible languages” in the Tower of Babel, have a coordination delay of up to 17 seconds. While the data synchronization accuracy of the PL-15E and ZDK-03 early warning aircraft is 0.3 seconds.

The more brutal truth is that the PL-15 missile that India captured is just a “downgraded” version that China exported. The range of the PL-15 version equipped in the Chinese Air Force has exceeded 200 km and the accuracy of the AESA self-guided radar is 256 gallium nitride elements, twice that of the export version.

This generation gap is like trying to catch up with a quantum computer with an abacus. While India is still trying to understand the missile technology produced by China in 2015, the Chinese defense industry is developing weapons to support sixth-generation aircraft.

In the international arms market, an engineer from the American Raytheon Company, after witnessing the out-of-sight air battle between the Indian and Pakistani air forces on the night of May 7, said that China's PL-15 missile is not inferior to the American AIM-260 missile.

Meanwhile, the French defense industry giant Dassault is worried about the Rafale fighter's legendary status, and announced overnight that it will upgrade the radar system on the Rafale fighter. Of course, the upgrade cycle will be completed in three years and the price of this aircraft will continue to increase.

While Russia has used this opportunity to promote its Product-180 missile for its Su-57 stealth fighter, claiming that it was specifically designed to defeat Ukrainian fighters; but this air-to-air missile has a range of only 150 km.

India has now established a "special research group" to study China's defense industry model, to apply to India. But will India learn from it, when the Chengdu Aviation Group's production line is capable of producing the J-20 stealth fighter, with a capacity of 50 aircraft/year;

While the Precision Ceramics Research Institute in Jingdezhen, Jiangxi Province, has made a breakthrough in gallium nitride component technology in the 6G communication band, the research on a 10-year-old Chinese air-to-air missile is not really of much help to the development of the Indian defense industry.

The 40-year-old "Made in India" mentality of the Indian defense industry was completely exposed in the air battle on May 7. We can see that the Arjun tank, launched in 1983, is still in the final stage. The development cycle of the Tejas fighter jet is longer than the construction of China's aircraft carrier, not to mention the Akash air defense system, which entered service 30 years ago but was not "present" in the recent air battle.

While India was celebrating the recovery of the PL-15 missile, researchers in a wind tunnel laboratory in southwest China were recording the test parameters of their sixth-generation air-to-air missile.

The current plight of the Indian defence industry is a wake-up call for all developing countries – without an independent innovative industrial system, all they can achieve is the remnants of a technological civilization.

Source: https://khoahocdoisong.vn/an-do-thu-giu-ten-lua-pl-15-vu-khi-trung-quoc-bi-sao-chep-post1543813.html

![[Photo] National Assembly Chairman Tran Thanh Man attends the VinFuture 2025 Award Ceremony](/_next/image?url=https%3A%2F%2Fvphoto.vietnam.vn%2Fthumb%2F1200x675%2Fvietnam%2Fresource%2FIMAGE%2F2025%2F12%2F05%2F1764951162416_2628509768338816493-6995-jpg.webp&w=3840&q=75)

![[Photo] 60th Anniversary of the Founding of the Vietnam Association of Photographic Artists](/_next/image?url=https%3A%2F%2Fvphoto.vietnam.vn%2Fthumb%2F1200x675%2Fvietnam%2Fresource%2FIMAGE%2F2025%2F12%2F05%2F1764935864512_a1-bnd-0841-9740-jpg.webp&w=3840&q=75)

Comment (0)