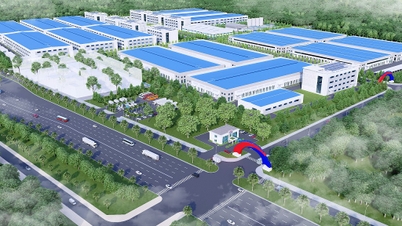

HANOI - In a 12,000 m2 factory at Noi Bai airport, about 300 engineers and technicians are busy repairing and maintaining various types of aircraft to ensure their operations.

VAECO's 12,000 square meter aircraft repair workshop No. 2 can accommodate four narrow-body aircraft and one wide-body aircraft, and can maintain and repair many aircraft every day.

There are currently 2 workshops located in Noi Bai airport, specializing in maintenance and supply of materials for aircraft types A319, A320, A321, A330, A350, B737, B757...

Engineer Tung Anh (left corner) and Nhu Hoang prepare tools to check the engine of the A350 that has just been brought into the workshop. To ensure smooth work and quickly return the plane to operation, about 300 people were mobilized to work.

Engineers install the blowback system of the V2500 engine on the A321 aircraft. This system has the task of protecting the main part of the engine and helping to reduce the speed of the plane when landing. Therefore, according to engineers, this assembly requires absolute precision.

"When the plane is in operation, there will be vibrations, which can easily cause the screws or pipes to loosen, causing a safety hazard. Checking and tightening the screws helps prevent this risk," said engineer Dinh Van Thanh, with 11 years of experience in aircraft repair, while working.

The engines of an A350 aircraft due for routine maintenance are removed for inspection.

Removing large equipment such as flaps requires multiple people and a crane.

After completing the maintenance inspection and necessary equipment replacement, the engineers will close the engine cover and check the technical parameters before handing it over to the operator.

The staff checked the tires and nose gear of the plane.

The A350 was towed out to the parking lot by a specialized vehicle for continued operation.

According to engineers, depending on the condition of the plane, maintaining and repairing one can take several days to a month.

"The profession of aircraft engineer often has to deal with noise, weather conditions, chemicals, grease, working in closed spaces, working at heights. All operations when carrying out repairs and maintenance must comply with available documents to avoid errors during the implementation process," said Mr. Duong Tu Con, Head of Technical Team, Technical Department, Hanoi On-site Maintenance Center.

In front of the factory, many planes lined up waiting for maintenance and repair.

The Maintenance Engineering major includes subjects such as aerodynamics; flight mechanics and flight control; aviation structures; propulsion systems; aircraft design and maintenance. The Maintenance Engineering major with a B1/B2 certificate (aircraft maintenance engineering certificate) includes: the Maintenance Engineering program content and an additional 1,329 hours of in-depth training on aircraft systems and maintenance practice according to the B1/B2 program. Graduates have a starting salary of 15 million VND, with seniority of about 35 million VND.

![[Photo] Panorama of the 2025 Community Action Awards Final Round](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/11/15/1763206932975_chi-7868-jpg.webp)

![[Photo] General Secretary To Lam receives Vice President of Luxshare-ICT Group (China)](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/11/15/1763211137119_a1-bnd-7809-8939-jpg.webp)

![[Photo] Prime Minister Pham Minh Chinh meets with representatives of outstanding teachers](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/11/15/1763215934276_dsc-0578-jpg.webp)

Comment (0)