Many local enterprises have gradually improved production processes, invested in technology, and applied advanced management systems, thereby improving business efficiency and competitiveness in the market.

Change in perception, practical effectiveness

Mr. Ta Chi Dong Luan - Deputy Head of the Department of Standards, Metrology and Quality (Department of Science and Technology) said: "The implementation of the program in the past time has basically followed the goals, suitable to the specific development conditions of the locality. The most important thing is that enterprises have been more proactive in approaching and applying advanced tools and systems to improve product quality."

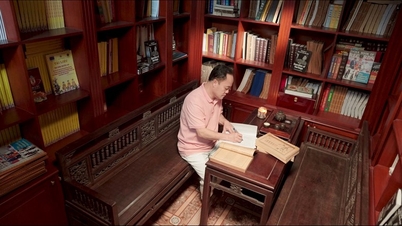

Nhan Hoa Company Limited applies 5S-Kaizen and ISO 22000 system in production. Photo: T.Loi

Up to now, 22 enterprises in the area have been supported to deploy pilot models applying management tools such as 5S, Kaizen, TPM, MFCA..., exceeding the original plan. Through the program, many units have become familiar with the concept of total quality management for the first time, thereby strongly transforming their management thinking and production organization. Nhan Hoa Company Limited (Hoai Nhon Nam Ward) specializes in producing sesame rice paper with the brand name "Dalop". Thanks to the support from the program, the Company has synchronously applied 5S-Kaizen and the ISO 22000 system in production.

Mr. Pham Quoc Bao - Director of the Company - shared: "Thanks to the support from the program, we have improved product quality, reshaped management thinking in a more professional and modern direction. Notably, at the end of June this year, the Dalop Sesame Rice Paper product M4 special type was recognized by the Ministry of Agriculture and Environment as meeting 5-star OCOP standards."

Not only supporting small and medium enterprises, the program also creates a clear change in large-scale enterprises. A typical example is Binh Dinh Agricultural Technical Materials Joint Stock Company, which has synchronously applied the ISO 9001:2015 quality management system, ISO 14001:2015 environment and 5S and Kaizen improvement tools into production and business. In particular, the deployment of an automatic monitoring system at Long My Fertilizer Factory (in Quy Nhon Tay ward) helps to strictly control the process, optimize operations and improve the quality of "New Sun" NPK fertilizer products. Thanks to that, in 2022, the enterprise was awarded the National Quality Gold Award, demonstrating the practical effectiveness of the program.

A solid foundation for the new phase

According to Mr. Ta Chi Dong Luan, the National Program to support enterprises in improving productivity and product quality in the period of 2021 - 2025 in the province not only helps the business community in Gia Lai access modern management systems such as ISO 9001, ISO 14001, ISO 22000, HACCP, TPM, Kaizen, Lean, Six Sigma..., but also applies the construction of a system to trace the origin of products and goods; good agricultural practices (VietGAP)... Thereby, contributing to improving competitiveness and increasing product value in the market.

Production activities at Long My Fertilizer Factory (Binh Dinh Agricultural Technical Materials Joint Stock Company). Photo: T.Loi

Since its operation in 2022, Green Farm Trading Service Company Limited (in An Nhon Tay commune) has continuously strived to improve production and enhance product quality. After implementing VietGAP, ISO 22000:2018 and HACCP standards, in 2024, the Company continued to participate in the Project to build a product traceability system chaired by the Department of Standards, Metrology and Quality. Although initially applying, it encountered difficulties due to the new system and complicated software operations; however, with the close support and guidance from the Department, the Company quickly mastered the system and effectively applied it to production and business management practices.

Mr. Nguyen Hong Thoa - Director of the Company - said: "Applying traceability not only helps us control the entire production process but also creates the necessary transparency for consumers. In the context of widespread counterfeit and poor quality goods like today, transparency is a competitive advantage. Thanks to that, we have increased consumption output, expanded the market and gradually enhanced the brand reputation."

In the western part of the province, many enterprises have been operating effectively thanks to the application of advanced management systems. Notably, Chu Prong Rubber One Member Co., Ltd. (Chu Prong commune). Accordingly, the Company has boldly applied ISO 9001 and ISO 14001 standards to its operations and production. Thanks to that, the Company has significantly improved its operational efficiency, strictly controlled product quality, improved the working environment and optimized production efficiency. The innovation efforts have been duly recognized, when the Company was honored to receive the National Quality Gold Award.

Sharing about the upcoming orientation, Mr. Truong Quang Phong - Deputy Director of the Department of Science and Technology - affirmed: Productivity and quality are the keys to sustainable development. In the period of 2026 - 2030, the unit will continue to promote communication, training, support digital transformation, apply advanced management systems, develop human resources and improve the capacity of on-site inspection organizations. Standardizing production and increasing product value is the inevitable path towards a modern, green and sustainable production.

Source: https://baogialai.com.vn/chuong-trinh-ho-tro-doanh-nghiep-nang-cao-nang-suat-chat-luong-san-pham-nhung-dau-an-tich-cuc-post568784.html

![[Photo] President Luong Cuong attends the 50th Anniversary of Laos National Day](/_next/image?url=https%3A%2F%2Fvphoto.vietnam.vn%2Fthumb%2F1200x675%2Fvietnam%2Fresource%2FIMAGE%2F2025%2F11%2F27%2F1764225638930_ndo_br_1-jpg.webp&w=3840&q=75)

![[Photo] Prime Minister Pham Minh Chinh chairs the 15th meeting of the Central Emulation and Reward Council](/_next/image?url=https%3A%2F%2Fvphoto.vietnam.vn%2Fthumb%2F1200x675%2Fvietnam%2Fresource%2FIMAGE%2F2025%2F11%2F27%2F1764245150205_dsc-1922-jpg.webp&w=3840&q=75)

Comment (0)