|

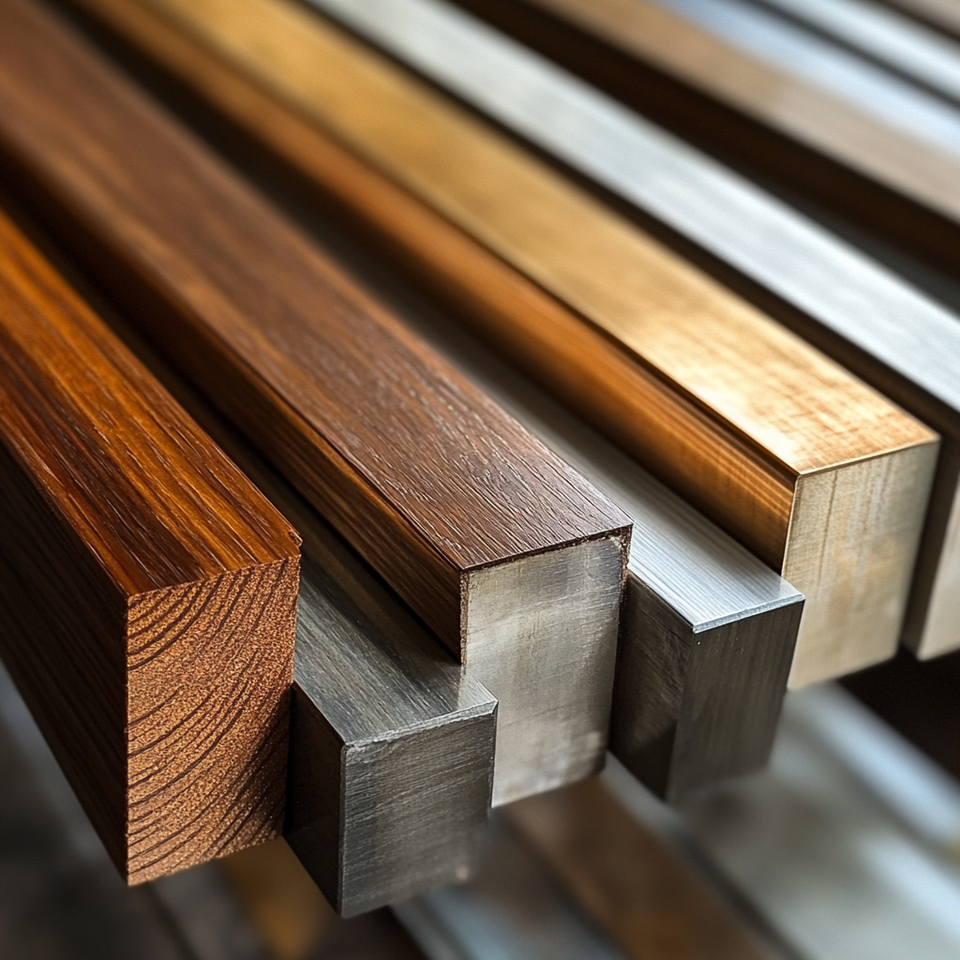

This type of wood has a compact structure and is as durable as steel. Photo: InventWood . |

In 2018, Liangbing Hu, a materials scientist at the University of Maryland, figured out how to turn ordinary wood into a material that is stronger than steel. Now, the technology is about to be put into mass production.

At first, the experiment seemed like a remarkable discovery that would eventually remain in the gallery. Many people approached Hu about the business, but he told them that he was just a university professor and had no idea what to do with the project.

Rather than give up, however, Hu spent the next few years refining the technology, reducing the time it took to produce the material from over a week to just a few hours. Before long, the technology was ready for commercialization, and he licensed it to InventWood.

The startup is now producing its first batches of Superwood, starting this summer. Alex Lau, CEO of InventWood, said the first commercial plant of its kind is small. The initial products will be used to build the “skin” of a building, the non-load-bearing parts that still require aesthetics and durability.

In the long term, they want to move towards replacing the backbone of the building from traditional materials to super-hardwood. “Because 90% of the carbon emissions from buildings come from concrete and steel during construction,” said Mr. Lau.

To build the plant, InventWood raised $15 million in its first Series A round. The round was led by the Grantham Fund, with participation from Baruch Future Ventures, Builders VC, and Muus Climate Partners, three prominent funds investing in sustainable technology, climate, and materials innovation.

Superwood starts with regular wood, which is primarily composed of two compounds: cellulose and lignin. In fact, nanocrystalline cellulose is actually stronger than carbon fiber. So the main goal is to enhance the strength of this inherent essence of wood.

The company uses chemicals used in the food industry to modify the molecular structure of wood, then compresses the material to increase the number of hydrogen bonds between cellulose molecules.

|

Superwood is 10 times more durable than regular wood. Photo: InventWood. |

With the ability to compress material four times, many people would think Superwood is stronger by the same amount. “But it is actually about 10 times stronger due to the additional bonds created during this process,” Lau explains.

The result is a material with a 50 percent higher breaking strength than steel and a strength-to-weight ratio 10 times better, the company says. It also meets Class A fire standards, meaning it is highly resistant to fire and is resistant to rot and insect damage.

When infused with polymer, it is stable in outdoor conditions, suitable for use as siding, outdoor flooring or roofing. Mr Lau shared that the compression process also deepens the color, making it look like high-end tropical hardwood.

In the long term, InventWood plans to use wood shavings, which are often waste products in the manufacturing process, to create structural beams of any size. They can look as good as natural high-end woods (like walnut or ipe), without any additional cosmetic treatments, Lau said.

Source: https://znews.vn/cong-ty-san-xuat-go-cung-hon-thep-post1552998.html

Comment (0)