At a press conference on April 8, White House press secretary Karoline Leavitt cited US President Donald Trump's views on the possibility of bringing iPhone production to the US.

Previously, US Commerce Secretary Howard Lutnick also talked about the prospect of American workers having jobs in high-tech iPhone manufacturing factories.

"Millions and millions of people are turning little screws on iPhones, we're going to bring them back to America and we're going to automate that," Lutnick said on CBS's Face the Nation on April 7.

The statements came after Mr. Trump announced tariffs and reciprocal duties on many countries, including China at a rate of 104%. This has a big impact on Apple because China is a key market for iPhone production.

According to the technology news site 404 Media , the idea of manufacturing iPhones in the US has been a topic that has “haunted politicians ” for years. However, the process of setting up an entire production line and recruiting a workforce in the US is not simple.

iPhone 16 on display at Apple's launch event. Photo: Bloomberg. |

Can't change overnight

Economists and manufacturing experts have been trying to figure out how much an iPhone made in the United States would cost in recent years. In 2018, a Quora answer suggested it could be as high as $30,000. Reuters ’ calculations, based on Trump’s tariffs, put the figure at $2,300.

Of course, this is all speculation. According to 404 Media , Apple can’t manufacture iPhones in the US overnight. In theory, the company could build assembly lines, but that would take years.

“In Trump’s ideal world , every company would move production back to the US at once, causing supply chain and factory construction problems and exacerbating America’s talent shortage in high-tech manufacturing,” the news site said.

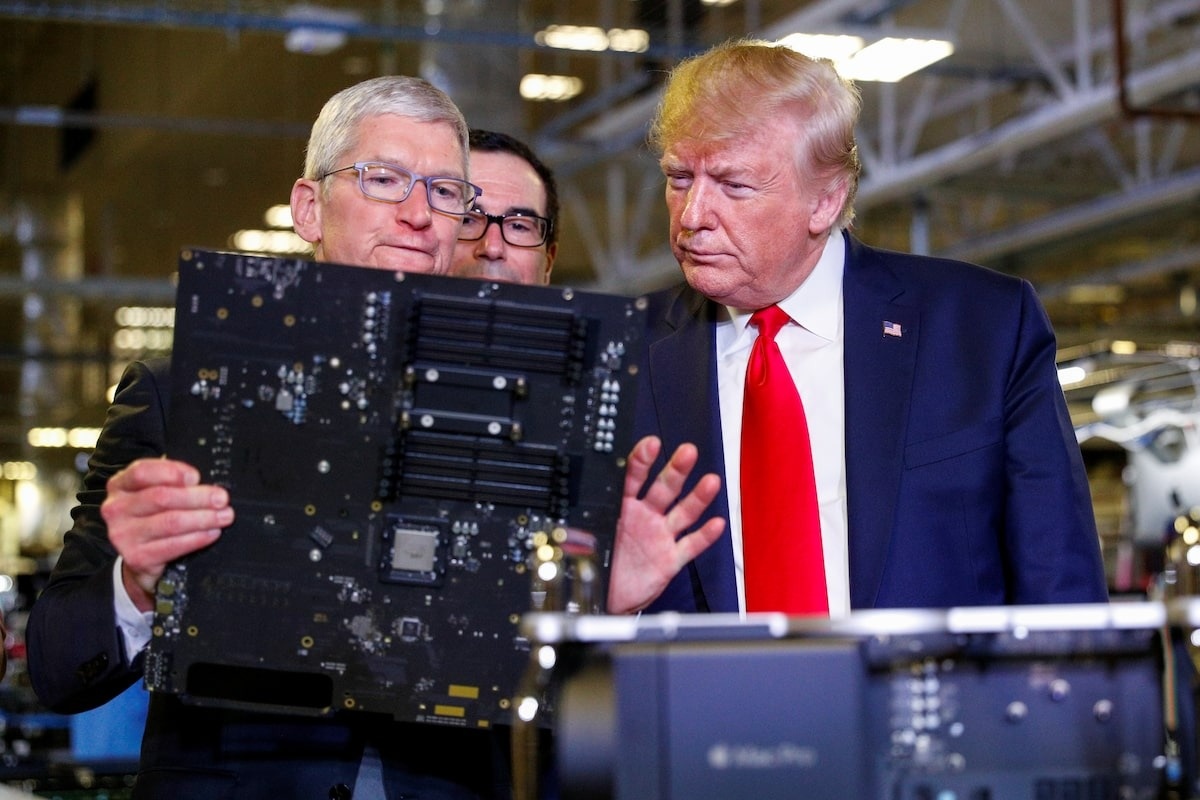

Apple CEO Tim Cook shows Mr. Trump the motherboard of the Mac Pro, a computer model Apple assembled in the US in 2019. However, many components of the Mac Pro still have to be imported from other countries. Photo: Reuters. |

In the long term, some high-tech manufacturing may move back to the US due to strategic and national security reasons. However, in the short term, with huge tariffs, this could have an unpredictable impact.

Even though the iPhone is assembled in the US, it still contains components made all over the world, with materials mined from dozens of countries. Apple has one of the most complex supply chains in history, and it won’t change overnight.

Global Supply Chain

Even the Mac Pro, which is advertised as “assembled in the USA,” has had to move some of its production to China. The Mac Pro is assembled in the US from materials mined from around the world, converted into components manufactured by many countries.

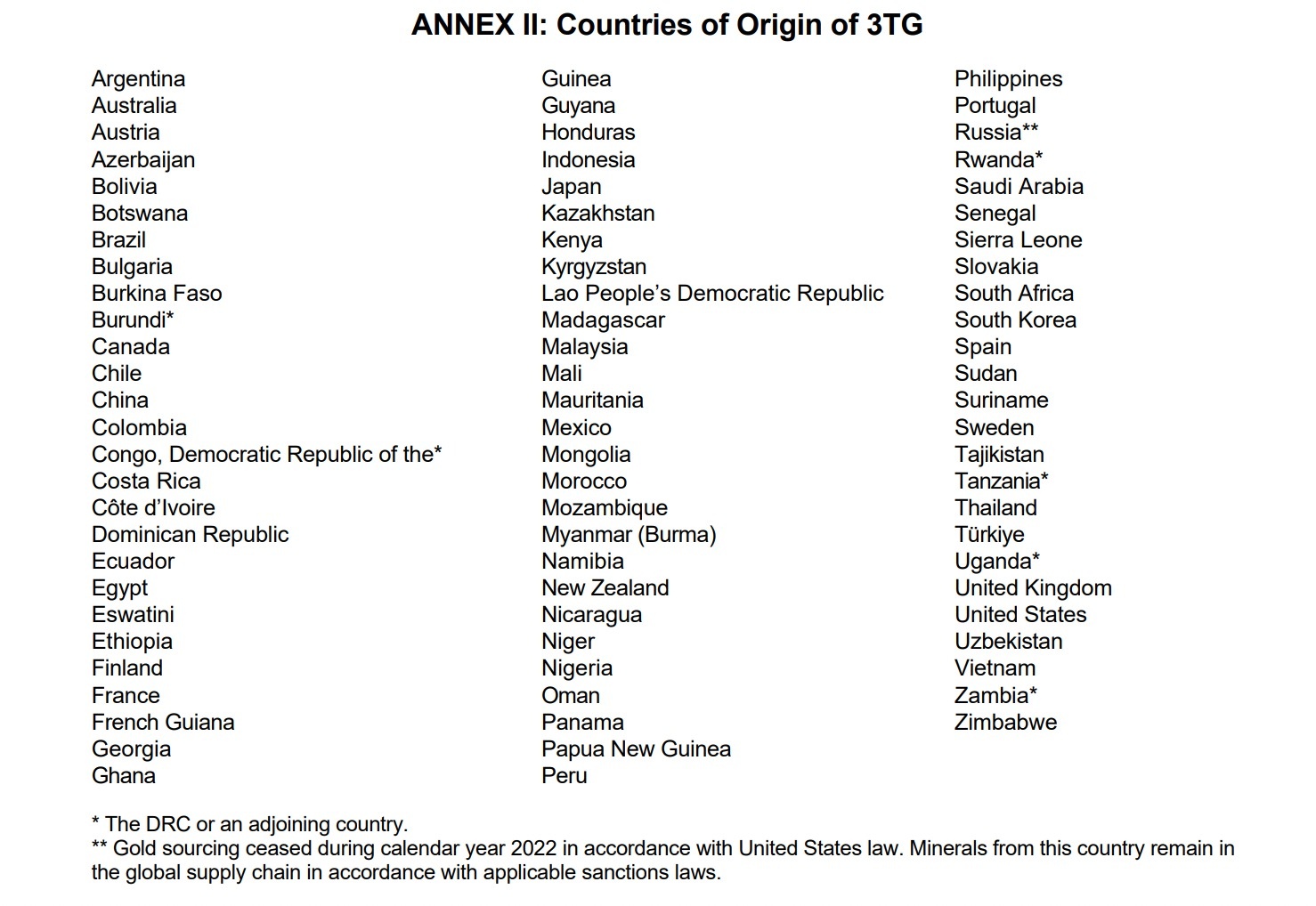

404 Media cited a mineral resources report filed by Apple with the US Securities and Exchange Commission (SEC). The document details the importers of tin, tantalum, tungsten and gold. Suppliers must also report the country of extraction.

The latest version of the document was filed in 2023. Of the four metals, they come from 79 countries, supplied by about 200 different refineries and smelters. Only 20 smelters come from the United States.

Some suppliers and countries and regions of origin in Apple's supply chain report. Photo: 404 Media . |

The longer list shows that the companies that make components for Apple are spread across dozens of countries. There are some in the US, but most of the factories are in Asia.

When Trump’s tariffs take effect, there is a theory that Apple will increase its sourcing of materials and components from American companies. However, Apple owns one of the most complex supply chains in the world, formed and adjusted over decades, not easy to change the whole thing in 1-2 years.

Supply chain documents show that Apple's manufacturing partners employ at least 1.4 million workers, and have more than 320 suppliers in total.

In a televised statement, Lutnick asserted that Apple would “automate its manufacturing army in America,” while American high school graduates would take on back-office jobs.

Countries of origin of 4 metals used to manufacture Apple devices. Photo: 404 Media . |

In fact, Apple's pace of automation is quite slow, with most of the company's products still assembled by hand.

This is a topic shared by Ryan Petersen, CEO of logistics company Flexport, on Bloomberg 's Odd Lots podcast .

“I talked to two people who had to put a pause on building a factory (in the US) because of tariffs, because the machinery they were going to buy was too expensive.

Factories need machines and components from many different countries. If the machines are too expensive, you will produce less. I don’t think that will bring the desired results,” Petersen said.

By 2024, The Information reports, Apple aims to reduce the number of people who assemble iPhones by “up to 50%.” But there are still millions of people doing that work. Even the process of disassembling and recycling iPhones still requires humans, even with the help of robots.

Recruiting millions of jobs

Training the workforce to assemble iPhones is also a concern. Even in the US, about half of the workers at TSMC’s chip plant in Arizona are from Taiwan.

In 2023, TSMC announced that its US factory “does not have enough skilled workers”, Taiwanese immigrants with special visas must take on most of the work.

For Mr Trump’s economic transition to go smoothly, the US needs to build a large number of high-tech factories at once. It should be noted that Foxconn had to cancel plans to build a factory in Wisconsin for various reasons despite receiving billions of dollars.

Responding to The Verge , project director Alan Yeung pointed out that the reason came from the impossibility of recruiting local workers.

Logo in front of an Apple store. Photo: Bloomberg . |

In 2024, Boston Engineering, a company that helps move tech manufacturing to the US, released a report on barriers to setting up production lines in the US, including higher wages, the need to build automation that may not yet exist, and a shortage of skilled workers in the US.

“Moving operations is not simply a matter of moving locations, but often requires redesigning products and manufacturing processes.

Many products were originally designed for low-wage manual labor overseas, and if brought back to the U.S., they would need to be redesigned for automation and higher-wage labor, the company said.

There have been numerous reports of harsh working conditions at Foxconn that have led to mental health problems among workers. Apple has taken steps to address these issues, but the most recent suicide of a Foxconn worker occurred in 2022, alongside a series of protests over working conditions and wages.

Bringing manufacturing back to the US is not just a goal of the Trump administration. Previously, the main goal of the CHIPS Act under Joe Biden was to bring chip manufacturing back to the US. However, the current tariffs are expected to have a major impact on the global supply chain and trade order, while not yet ensuring clear benefits.

Source: https://znews.vn/san-xuat-iphone-tai-my-la-vien-vong-post1544452.html

![[Infographic] In 2025, 47 products will achieve national OCOP](https://vphoto.vietnam.vn/thumb/402x226/vietnam/resource/IMAGE/2025/7/16/5d672398b0744db3ab920e05db8e5b7d)

Comment (0)