11/07/2024

In the context of African swine fever re-emerging and spreading in many localities, food safety has become a top concern. Masan MEATLife, one of the leading enterprises in the livestock and meat processing industry, has been implementing many strict measures to ensure a clean and safe food supply for consumers.

Mr. Nguyen Huynh Thai Hoang, National Production Director of Masan MEATLife, shared with Dan Viet reporters about the company's strategy and efforts in building a disease-free livestock farming area, while affirming the quality and price stability of MEATDeli chilled meat products.

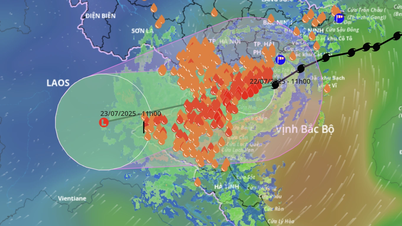

Mr. Nguyen Huynh Thai Hoang, in the context of African Swine Fever currently re-emerging and spreading in many localities such as Hai Phong, Bac Kan , Lang Son, Quang Ninh, Quang Nam, what has Masan MEATLife done to build disease-free livestock farming areas, ensuring food supply to the market?

We identify disease safety as a solid foundation to have the best input materials, from which we can have output of quality meat products, meeting the requirements of food hygiene and safety standards.

Our farms all meet GlobalGAP standards and are monitored and reassessed periodically. We are proud to be one of the companies selected as a pilot model in the Program to build a chain of biosafety facilities and disease control in the pig farming industry in Vietnam according to the international standards of the World Organization for Animal Health (WOAH) sponsored by IFC. This is one of the development finance institutions, a member of the World Bank, working hard for sustainable development in developing economies like Vietnam.

Building a chain of biosafety and disease control facilities is a big step that requires businesses to have a good foundation from breeding facilities to slaughterhouses and processing facilities that meet the most stringent standards of the World Organization for Animal Health. At Masan MEATLife, we have built a 3-line defense system to ensure that output products always meet food hygiene and safety standards. Specifically:

First, quarantine pigs at the farm: Healthy pigs from farms that meet VietGAP/GlobalGAP standards. The farm must ensure disease safety and the factory will take samples for testing using the PCR molecular biology method to ensure the pigs are healthy before being transferred to the factory.

Second, quarantine pigs before entering the factory: When pigs are brought into the slaughter and processing complex, along with the inspection and supervision of veterinary staff, pigs will be tested again in the 24/7 laboratories at the factory, to ensure that no sick pigs or pigs carrying pathogens are brought in for slaughter and processing.

Third, pork quarantine before leaving the factory: This final inspection ensures that MEATDeli chilled meat is free of pathogens. After slaughter, pigs are tested using the molecular biology method PCR to ensure that the meat is clean and disease-free.

So, to ensure the amount of chilled meat consumed in the market, what measures has the company taken to ensure the source of raw pork, sir?

At Masan MEATLife, we have developed a set of standards for chilled meat products and criteria for evaluating pig farms to diversify the source of live pigs from farms of suppliers that meet VietGAP/GlobalGAP standards. Through strategic cooperation with reputable partners, we are completely proactive in obtaining abundant and safe supply.

Nowadays, chilled meat products are no longer strange to consumers. What must the unit do to affirm and ensure the quality of the product?

As life is gradually improved, consumers pay great attention to products that ensure food hygiene and safety. To affirm and ensure the quality of our products, we have issued product standards and built a strict quality management system. Our slaughter and processing complex has achieved the BRC certificate of the British Retail Consortium - this is a certification for compliance with the standards of the Food Safety Management System, suitable for quality control and food safety, recognized and enforced by many countries around the world.

At Masan MEATLife, innovation is always the guiding principle for all activities, from production and business to distribution operations, or brand building. Therefore, in recent years, in addition to creating delicious, quality products that have been trusted and chosen by consumers, we have focused resources on developing human resources in the Research and Development department, in order to create an abundant resource to develop a large number of high-quality products while still ensuring reasonable profits. We understand that we need to have the companionship of consumers with excellent quality products in the spirit of serving Vietnamese consumers.

Pork prices are still subject to market influences. So what is the method to stabilize the price of MEATDeli chilled meat products?

Up to now, we are the only unit in Vietnam that produces chilled meat using European technology. The production process of these products is completely different from pork slaughtered in the traditional way. Therefore, we have to balance production costs and input pig prices to get a reasonable price.

Even though pork prices are still affected by the market, especially during holidays, Tet or due to objective reasons such as epidemics, we still ensure optimal cost per unit of product through the successful integration of the 3F chain (Feed - Farm - Food) (Chain "from farm to table").

Specifically, we have cooperated with experts in the field of genetic breeding to ensure healthy breeding sources to increase the number of livestock/litter. Selecting and cooperating with nutrition experts to create appropriate nutritional rations for livestock to ensure high livestock performance. At the same time, improving the capacity and productivity of workers is the premise for us to control well the cost of output products that are trusted and chosen by consumers.

Source: Dan Viet

Comment (0)