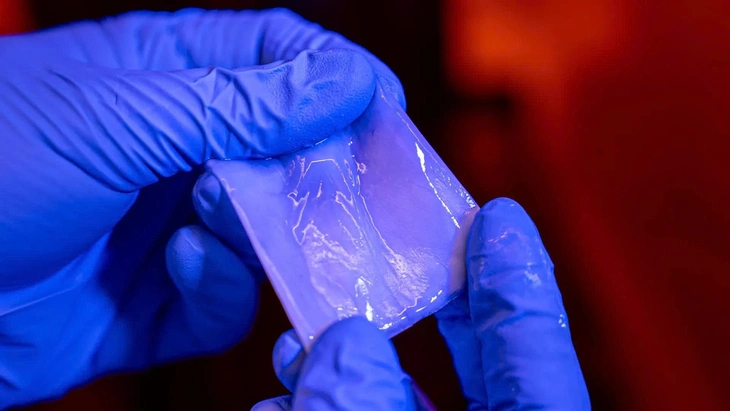

With its ability to remember shape and transform itself when stimulated by heat, this new type of liquid crystal material opens up a range of future applications - Photo: Jorge Vidal/Rice University

The study, published in the scientific journal Nature Communications on July 22, describes a novel biosynthesis process in which bacteria are "instructed" to produce cellulose fibers, one of the purest biomaterials on the planet. The result is a biomaterial with tensile strength of up to 553 megapascal, far exceeding that of conventional polymer materials.

New materials from bacteria and synthetic biology.

According to a research team led by Professor Muhammad Maksud Rahman (University of Houston), the new material is made from cellulose produced by bacteria, but differs in that the cellulose fibers are no longer formed randomly but are aligned thanks to a special biological rotation system called a "rotating bioreactor".

"We developed a rotating culture chamber to direct the movement of bacteria as they produce cellulose," said graduate student MASR Saadi. "Controlling the growth direction significantly increases the material's strength while maintaining its softness, transparency, and flexibility, similar to bioplastics."

Not only is it more durable, the research team also successfully integrated boron nitride nanolayers, allowing the material to conduct heat three times faster than the control sample, opening up potential applications in electronics, thermal packaging, and energy storage.

Many useful applications

Unlike traditional synthetic plastics, which cause micro-pollution and release toxic substances like BPA and phthalates, the new material is completely biodegradable and easily customizable for a wide range of uses such as packaging, textiles, building materials, green electronics, and batteries.

"This biosynthesis process is like training a disciplined team of bacteria," Saadi said, using an analogy. "We guide them in a specific direction, and from there create a product with the desired properties."

With its ability to remember shape and transform itself when stimulated by heat, this new type of liquid crystal material opens up a range of future applications. One of the promising deployments is soft robotics, flexible machines that can crawl, slither, and squeeze through narrow spaces without the need for complex mechanical mechanisms.

In medicine, this material can be used to create stents (vascular supports) or implantable devices inside the body that are flexible and change shape according to temperature or biological conditions, helping to minimize invasiveness and increase treatment effectiveness.

Additionally, they hold promise for applications in flexible electronic devices, smart sensors, and self-deploying structures in space.

Source: https://tuoitre.vn/tao-ra-vat-lieu-moi-ben-nhu-kim-loai-deo-nhu-nhua-2025072215151939.htm

Comment (0)