While Sam Altman wants to cure cancer and Elon Musk says AI will eradicate poverty, China's goal is to consolidate its role as the world 's factory for decades to come. At the same time, available technology will be used to increase efficiency, shorten production times, and reduce labor dependence.

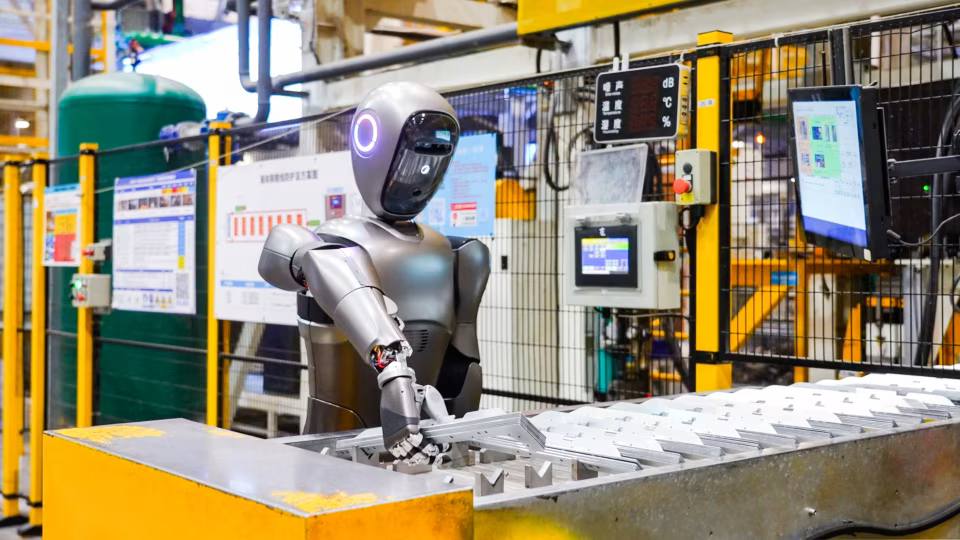

The country is rapidly integrating AI and robotics into its manufacturing sector to maintain its status as the “world’s factory” amid rising labor costs, an aging population, and global trade pressures. This is fueling the spread of “dark factories,” where operations are automated to the point of being 24/7 with minimal lighting.

Large-scale robot deployment

According to the International Federation of Robotics , China installed 295,000 industrial robots last year. At that time, the number of robots in operation in China exceeded 2 million, the highest of any country, nearly nine times that of the United States, and more than the rest of the world combined.

The country has 45 of the 131 factories and industrial facilities globally recognized by the World Economic Forum (WEF) for improving productivity through advanced technologies such as AI, while the US has only 3.

At the Baosteel “dark factory” in Shanghai, just three operators sit in front of dozens of screens to monitor real-time updates, according to local media. The facility’s deputy director said the need for human intervention has been reduced from every three minutes to just every 30 minutes thanks to AI.

|

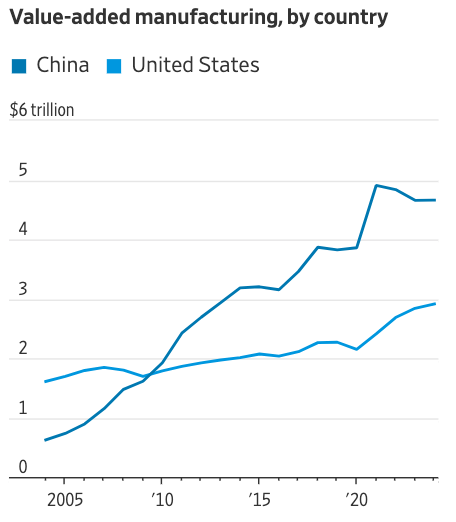

Value added in manufacturing industry (USD unit). Photo: WSJ. |

Strong factories are the foundation of a strong economy, with a quarter of China’s GDP coming from manufacturing, far higher than the global average. However, the WSJ said one risk is that AI could eliminate many factory jobs, leading to a labor surplus.

But China’s leaders believe that a shrinking population, expected to fall by 200 million over the next three decades, will offset the loss of industrial jobs, leading to increased productivity without unemployment.

AI can’t solve all economic problems, either. In areas like advanced AI and chips, China still lags behind the US. And many companies like Amazon and Walmart are also prioritizing automation in the same way Chinese companies are.

The computer brain that runs the factories

China’s advantage lies in the scale of its ambition. Areas like Jingzhou, a city of 5 million people on the Yangtze River, are home to Midea’s key manufacturing facilities.

Nearly a decade ago, Midea made its automation ambitions clear by acquiring control of Kuka, a German specialist robotics company. Today, the robots at Midea’s washing machine factory in Jingzhou operate under the coordination of an AI “factory brain” that acts as a central nervous system.

The brain manages 14 virtual agents, allowing them to communicate with each other to find the optimal way to perform tasks, then pass commands down to robots and other machines on the production floor. This is a step towards Midea's long-term goal of using AI to fully automate factory processes.

|

AI brains run factories. Photo: Midea. |

“Just feed in all the data and the AI will figure it out,” said Xi Wei, director of Midea’s Humanoid Robotics Innovation Center. Next, humanoid robots carry the molded parts to an inspection station, where a 3D camera evaluates them. If the parts fail, the AI system will figure out how to fix the problem.

When it comes to tightening screws on an assembly line with different dryer models, the brain can recognize the correct model so the robot can perform the appropriate operation, Xi said. In positions where human operators are still needed, some workers are equipped with AI-enabled glasses that can detect common product defects based on inspection history.

Processes that previously took 15 minutes can now be completed in just 30 seconds. Midea says revenue per employee increased by nearly 40% between 2015 and 2024.

Significantly increase efficiency thanks to AI

Along with DeepSeek, Huawei is at the center of China’s AI efforts, introducing a large family of language models called Pangu, along with other AI services that make factories more agile.

Huawei engineers have been working closely with the Conch Group, a giant cement producer in the city of Wuhu, whose cement products have been used in projects such as the Three Gorges Dam and the Burj Khalifa in Dubai.

Conch and Huawei have developed AI tools to more accurately predict the strength of clinker, a key ingredient in cement, and to control energy consumption at the kiln. Miles of conveyor belts at the Wuhu facility are now monitored by AI, helping Conch respond more effectively when problems arise.

With AI, Conch and Huawei say they can predict clinker strength with more than 85% accuracy, compared to 70% when manually estimating, allowing them to adjust the ratio of raw materials and avoid producing materials with substandard strength.

According to Conch, using the AI model has helped reduce coal consumption by 1%, saving nearly $300,000 per year on just one production line. The company aims to reduce it by 2% by the end of 2026.

|

Planning is moving much faster at Tianjin port. Photo: WSJ. |

Another priority for China is upgrading its port system, aiming to cement its position as a global manufacturing powerhouse. To do so, Tianjin Port, one of China’s largest, has partnered with Huawei to deploy a fleet of autonomous trucks and a system called OptVerse AI Solver, which optimizes tens of millions of variables to manage scheduling.

According to Huawei, planning work that used to take 24 hours now takes just 10 minutes. Last year, the port also launched PortGPT, an AI model developed with Huawei that can analyze video and images on the scene, which could allow them to replace safety personnel in the future.

In Tianjin, more than 88% of large container equipment has been automated, according to state media this year. A video tour of the port shows China’s growing faith in AI with the slogan “We are the future.”

Source: https://znews.vn/trung-quoc-buoc-vao-thoi-ky-nha-may-trong-bong-toi-post1606080.html

Comment (0)