A breakthrough device is expected to completely replace manual labor in cotton top cutting – one of the most labor-intensive and vulnerable links in the cotton production chain.

This is an important step towards complete automation of the agricultural sector.

Robots effectively replace human labor

Cotton topping is an essential technique to remove the apical buds, redirect nutrients to the lateral branches, promote boll formation and increase yield.

However, this technique has long had to be performed manually due to the high precision required and the specific differences of each plant, leading to low productivity, high labor costs and easy damage to crops.

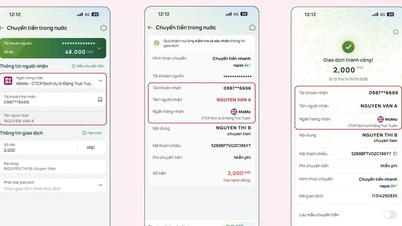

Actual photo of the world's first laser-cutting robot, introduced by Xinjiang University, China (Photo: SCMP).

Faced with that reality, researchers at Xinjiang University, in collaboration with EAVision Robotic Technologies, have built a specialized robot in Changji City, Xinjiang Autonomous Region – China's largest cotton production center.

The robot incorporates a combination of advanced technologies including a solid-state lidar scanner, vision-based recognition technology and a high-powered laser. This autonomous system is capable of “vaporizing” plant buds without touching the stem, minimizing biological damage.

In field conditions, the robot achieved 98.9% accuracy in bud detection, an 82% success rate in topping, and a plant damage rate of less than 3%.

Professor Zhou Jianping, head of the development team at Xinjiang University, likened the work to “shooting a moving target with a moving gun,” highlighting the complexity of locating bud tips on tall, wind-swaying, unevenly-height trees.

The goal of agricultural automation

In recent years, China has carried out a comprehensive revolution in the agricultural sector, aiming to build modern, precise and sustainable agriculture.

According to its five-year plan for smart agriculture (2024–2028), China aims to digitize the entire agricultural production chain, from planting to harvesting and distribution, through the deployment of big data platforms, IoT sensors, machine vision, and artificial intelligence.

China has ambitions to be a leader in smart agriculture (Photo: PanDaily).

By 2023, the mechanization rate of key stages will exceed 74%, while digital infrastructure systems such as 5G and broadband Internet will cover all rural areas.

More than 2,600 rural logistics centers and 150,000 commune-level delivery points have boosted e-commerce, with online agricultural product sales reaching 2.17 trillion yuan by 2022.

China is also investing heavily in agricultural robots, smart greenhouses and integrated energy-agriculture models, demonstrating its determination to lead the world in the trend of automation and digitalization of the agricultural sector.

Xinjiang, which supplies more than 80% of China’s cotton, has long been the focus of the global cotton industry, but the region faces many constraints, including harsh natural conditions, a scattered population, and labor pressures.

Therefore, the shift to automated manufacturing is seen as a vital strategic goal.

Illustration of a model of a self-driving tractor combined with a drone in a field (Photo: Xinjiang Daily).

China has invested heavily in equipment such as automated harvesters, GPS-enabled seeders, and agricultural drones. However, the topping process remains the last remaining bottleneck. Now, with the introduction of a laser topping robot, it could be the final piece of the puzzle to complete the automation loop.

On a broader scale, this technology could serve as a model for other countries to learn from, highlighting the role of precision agriculture combined with high technology, while reducing dependence on human labor, increasing productivity and protecting farming ecosystems.

Source: https://dantri.com.vn/khoa-hoc/trung-quoc-cach-mang-hoa-nong-nghiep-bang-robot-cat-ngon-20250716083424969.htm

![[Photo] Chairman of the Hungarian Parliament visits President Ho Chi Minh's Mausoleum](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/10/20/1760941009023_ndo_br_hungary-jpg.webp)

![[Photo] Prime Minister Pham Minh Chinh meets with Speaker of the Hungarian National Assembly Kover Laszlo](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/10/20/1760970413415_dsc-8111-jpg.webp)

![[Photo] National Assembly Chairman Tran Thanh Man holds talks with Hungarian National Assembly Chairman Kover Laszlo](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/10/20/1760952711347_ndo_br_bnd-1603-jpg.webp)

Comment (0)