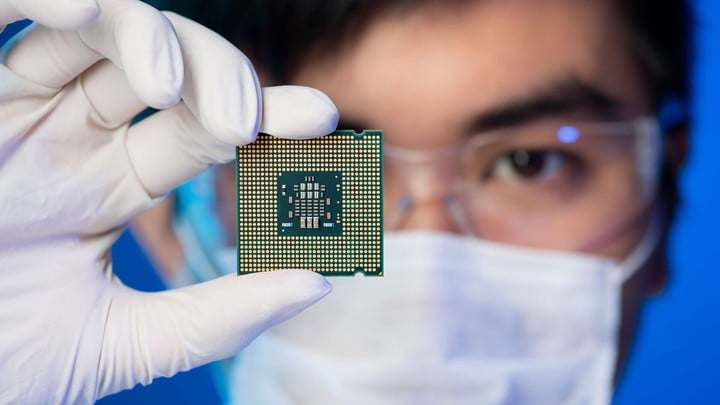

Therefore, the "chip war" - the competition to control semiconductor technology - has become one of the most fierce conflicts. In that context, the issue of ensuring security and autonomy in Vietnam's chip manufacturing technology, especially in the context of the strong national digital transformation taking place, is of primary concern...

Need for self-sufficiency in production to minimize security risks

According to Associate Professor Dr. Thai Truyen Dai Chan, member of the CTGroup Scientific Council, the current competition for control of semiconductor chips between the superpowers is not only a commercial issue, but also a geopolitical war, because whoever controls semiconductors will control most of the technological power in the future.

Therefore, if a country cannot master integrated circuits, the risks will be extremely high. First of all, in terms of economics, just one fluctuation in the global supply chain, such as an epidemic or trade tensions, can paralyze a series of manufacturing industries. This directly affects GDP, employment and social stability. Second, in terms of security and defense, all modern military systems, from radar, satellites, UAVs, to high-precision weapons, depend on semiconductor components. If the supply is cut off, the defense capability will be reduced. More dangerously, imported circuits can be installed with "security holes" (backdoors), creating the risk of illegal intrusion, threatening national sovereignty. In addition, dependence also hinders the process of technological innovation.

Any country that wants to develop AI, IoT, electric vehicles or next-generation telecommunications infrastructure needs the right microchips. Relying on imports alone will result in high costs, slow innovation and the risk of foreign manipulation.

According to experts, for Vietnam, chip autonomy requires a realistic and selective roadmap.

This view is agreed by Colonel, Dr. Le Hai Trieu, Director of the Institute of Professional Electronic Engineering under the Department of Security Industry ( Ministry of Public Security ) because currently the microchip design stage is done very well by some domestic enterprises; but the production is still abroad and this is related to security risks and costs.

According to Mr. Tran Kim Chung, Chairman of the Board of Directors of CT Group, if we cannot be self-sufficient in production, we may also lose national data, or may not be proactive in emergency situations. "We need to create "Made by Vietnam" products to serve both the people, national defense, security and compete equally in the world market," Mr. Chung said.

Selective production autonomy

According to experts, for Vietnam, chip self-sufficiency requires a realistic and selective roadmap. It is difficult for us to compete directly in the ultra-advanced semiconductor segment, which requires tens of billions of USD in investment capital and decades of technology foundation. However, we can focus on practical areas that are closely related to domestic needs. For example, low- and medium-power microchips for IoT (Internet of Things), sensors, smart devices and 6G infrastructure, are areas with large markets and suitable for current capacity.

Businesses can focus on security circuits, serving e-government, defense, UAVs (unmanned transport aircraft) and smart identification - where Vietnam has strengths thanks to cybersecurity research.

Or it can focus on dedicated circuits (ASIC/FPGA) for smart transportation, AI (artificial intelligence) at the edge and defense applications. Focus on energy and electric vehicle ICs, such as battery management, motor control, energy conversion, in line with the green industry development orientation.

Mr. Le Hai Trieu suggested that in reality, the chips used for Vietnam's ID cards and passports are being widely used in the world (the market share of EMV, eID, and e-Passport chips accounts for 95% of the world) and will continue to be used in the future for at least 20-25 years without becoming obsolete. Therefore, domestic semiconductor enterprises should focus on producing these products. In addition, manufacturers should connect researchers, policymakers, and technology enterprises to promote core technology autonomy for sustainable digital transformation.

Also according to Mr. Le Hai Trieu, currently the Ministry of Public Security has assigned the Institute of Professional Electronic Engineering (Department of Security Industry) to preside over the project: "Research, development and technology transfer to master semiconductor microchip technology to ensure national defense and security" to submit to the Prime Minister in 2025.

According to Chairman of the Board of Directors of CT Group Tran Kim Chung, with the experience of successfully researching and designing ADC semiconductor chips (analog to digital data conversion) announced in early July; designing a chip usually takes about 2 years. To have a product, it must go through the stages of research, design, photolithography, testing, and packaging. If it is an MCU chip - microprocessor chip, serving digital conversion; telecommunications chip, remote sensing... requires a more complicated process. Thus, if we simultaneously make all the necessary chips from now, it will take until 2027 to have them. While the digital conversion process is making great strides, every hour saved is precious.

"The competent authorities, the Ministry of Public Security and the Ministry of National Defense, should decide and submit to the Government the chip lines that must be developed domestically. On the business side, we are ready to work with Hanoi National University to make efforts to research, develop and respond. That is the way for us to be proactive and self-reliant," said the Chairman of the Board of Directors of CT Group.

CT Group leaders also proposed that Hanoi National University and CT Group could cooperate with units of the Ministry of Public Security and the Ministry of National Defense to jointly research and develop standard products based on various types of chips. And CT Group, in addition to its strength in making chips, can also make circuit boards, sensors, and drones (it has signed an MOU to export 5,000 UAVs to Korea), ready to meet market demand.

Thus, it can be seen that when building a focused strategy and long-term investment, Vietnam can completely be self-sufficient in key segments, thereby ensuring technological security and enhancing its position in the global value chain./.

Source: https://mst.gov.vn/tu-chu-san-xuat-chip-an-ninh-cho-qua-trinh-chuyen-doi-so-19725101918150709.htm

![[Photo] Prime Minister Pham Minh Chinh meets with Speaker of the Hungarian National Assembly Kover Laszlo](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/10/20/1760970413415_dsc-8111-jpg.webp)

![[Photo] Prime Minister Pham Minh Chinh received Mr. Yamamoto Ichita, Governor of Gunma Province (Japan)](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/10/21/1761032833411_dsc-8867-jpg.webp)

![[Photo] National Assembly Chairman Tran Thanh Man holds talks with Hungarian National Assembly Chairman Kover Laszlo](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/10/20/1760952711347_ndo_br_bnd-1603-jpg.webp)

Comment (0)