Hard work accumulates little by little

2024 ended with impressive numbers for Biwase: revenue increased by more than 10%, exceeding expectations; although profits did not meet the target, they were more than enough to ensure a 13% dividend for shareholders - a number that is enough to satisfy both small investors and large investment funds.

For Mr. Nguyen Van Thien, Chairman of Biwase's Board of Directors, these results are not only the achievements that the Company has laid the foundation for in the past, but also the driving force to move forward, because 2025 marks the milestone of the Company turning 50 years old.

Sitting pensively with a cup of tea, Mr. Thien recalled 30 years ago, from the early days of taking over Biwase, when it was the Song Be Water Supply Center. At that time, the water supply system here consisted of only 10 underground wells, and the pumps "broke down easily". "Every time the pump broke down, it took a whole week to repair. People lacked water, and the government was upset. Every night I couldn't sleep," he said.

But it was those hard days that fueled his will. He boldly proposed to switch from groundwater to surface water. “Small-scale business cannot last long, so I boldly proposed a change and luckily the government gave me the green light,” Mr. Thien shared.

Conversion is one thing, but how to operate smoothly is another. In 1997, Thu Dau Mot Water Plant with a capacity of 15,000 m3/day and night was established, but wherever water flowed, there was loss. Because of the subsidy period, the Company did not have specialized materials, had to use what was available and produce manually. Many pipes leaked, the Company had to reinforce them, but the old pipes, so patching one place, leaked another, causing water loss of up to 70%.

Day after day, he and his fellow workers went everywhere, fixing each pipe section. Before they could finish, VSIP came to Binh Duong to open an industrial park, and they registered 12,000 m3 of water for use.

In 1997, when the 12km D400 pipeline was brought to supply water to VSIP I Industrial Park, everyone was happy. Because this changed the mindset about water supply services for domestic and industrial use in the province. But the difficulties were just beginning.

“At that time, the industrial park had just built infrastructure, with a total registered area of 12,000 m3, but only 4,000 m3 were used. The investment cost was high, but there was no output, causing the company to suffer heavy losses. It took 2-3 years, when VSIP I attracted many secondary investors, for us to relieve the pressure,” the Biwase leader said sadly.

When the output problem was solved, Biwase still faced the problem of preventing water loss. Mr. Thien researched many methods, learned from the experiences of experts and colleagues at home and abroad, and then decided to use the technology of installing frequency converters to adjust the general pressure, adjust the pressure day and night... to help reduce the water loss rate to below 50%. "I am very happy to save a sum of money, I have to accumulate little by little".

Although the loss rate has decreased, the number is still too large. Thanks to the first ODA capital of 350,000 USD from Japan's OECF, Biwase bought 10 km of Kubota cast iron pipes and determined to replace the entire old pipeline system, despite the risks and skeptical eyes.

“I risked my life to replace all the old pipes, both American and French pipes that were still usable. If I had to go to jail, I would accept it, because if I didn’t do it, I don’t know when I would be able to get better,” he said. And that risk brought results – the loss rate dropped sharply, to less than 5%.

Biwase's success has created trust among provincial leaders, ministries, branches and capital sponsors. Up to now, Biwase has built clean water pipelines throughout Binh Duong province and some other localities, with a total maximum capacity of 1 million m3/day and night, with 8 water supply plant clusters using surface water from two major rivers, Dong Nai River and Saigon River.

Turn waste into resources

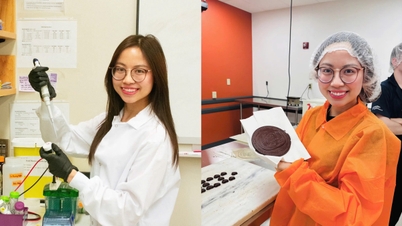

Not stopping at the water industry, Mr. Thien is also the one who laid the foundation for waste treatment and developed recycled products. Biwase has deployed modern treatment technologies, from waste classification, composting, to producing bricks from incinerator ash.

Biwase's expansion into the environmental field was by chance. In 2004, the media was "stirred up" with the phrase "Ho Chi Minh City embraces Binh Duong's garbage". At that time, Mr. Thien was asked by the provincial leader if he could handle the garbage. With determination, he replied that he could. So, in addition to the task of providing clean water, Biwase was officially assigned the task of environmental treatment.

Biwase is ahead of its time with a circular economic model, from water supply to waste treatment, from sludge to recycled bricks, each activity is associated with sustainable development criteria. Biwase does business not only to make a profit, but also to leave good values for the community. If today we spend an extra penny to protect the environment, tomorrow we will earn many pennies from protecting users' health and the sustainable development of society.

Biwase is ahead of its time with a circular economic model, from water supply to waste treatment, from sludge to recycled bricks, each activity is associated with sustainable development criteria. Biwase does business not only to make a profit, but also to leave good values for the community. If today we spend an extra penny to protect the environment, tomorrow we will earn many pennies from protecting users' health and the sustainable development of society.

- Mr. Nguyen Van Thien, Chairman of Biwase Board of Directors

Within 6 months, Biwase cleared 60 hectares of land to build a temporary treatment area. In the early days, the company only created a landfill with a waterproof lining and a leachate collection system. But he soon realized that landfilling was not a long-term solution. Burying waste was pushing the problem to the future. We had to find ways to recycle and utilize waste to create value.

Through his study trips abroad, he found that in developed countries, organic waste is often composted, while non-recyclable waste is burned to reduce volume and utilize energy.

The decision to switch to incineration was not simple. At that time, building an incinerator required a large investment cost, while the Company's financial capacity was limited. "I thought, if foreigners can do it, why can't we? They burn garbage and use the energy, we can also follow that path," he recalled.

In 2012, Biwase put the first incinerator into operation. But not everything went smoothly. 500 tons of waste burned, leaving more than 100 tons of ash. The problem is that the ash contains hazardous substances such as dioxin. If not treated, heavy rains will wash it into the fields, causing terrible pollution.

Realizing this, Biwase has built an additional ash treatment process. The ash after combustion is finely ground and mixed with cement to produce construction bricks. Like that, every day, from household waste to incinerator ash, everything is reused, forming a closed cycle.

Up to now, Biwase has created a circular waste treatment model, turning waste into "gold" to recycle into fertilizer, bricks, generate electricity... From August 1, 2023, Biwase will no longer bury waste in the Dong Nai river basin, but 100% of waste will be collected and classified.

In which, organic waste is composted to serve organic agriculture; nylon waste will be recycled; iron, steel, and metal will be collected and sold as scrap; construction materials are gathered to be used for leveling; other waste is burned and heat is collected to generate electricity; organic sludge is dried to make organic fertilizer; ash and inorganic sludge are mixed to make concrete, concrete structures, self-locking bricks, and sidewalks...

Currently, Biwase operates 4 waste treatment lines with a capacity of 2,520 tons/day, including a fermentation area of over 100,000 m3, a ripening factory of 56,800 m2, and a compost floor of 30,800 m2.

The company has 2 leachate treatment plants with a capacity of 1,000 m3/day; 2 medical waste incineration plants with a capacity of 16 tons/day and 4 mixed waste incineration plants with a capacity of 500 tons/day, including 1 heat recovery plant with a capacity of 5 MW. The system has enough capacity to receive all the domestic waste of Binh Duong province.

Towards sustainable growth

From a state-owned enterprise, then equitized and moved towards IPO, Biwase gradually dominated the water supply market in Binh Duong province and expanded to other potential markets such as Can Tho, Dong Nai, Long An, Quang Binh, Vinh Long... The company also expanded the scale of domestic and industrial waste treatment.

Throughout that journey, Mr. Thien has always been steadfast in his philosophy of “business must be responsible to the people around, the farmers around, and the workers around”. He shared: “I always tell my team that foreign investors do not need much profit, they need businesses that do business responsibly. We not only serve the community, but also build trust”.

Biwase's focus in the coming period will continue to deeply exploit two key areas: water and waste treatment, while expanding its scale with the goal of sustainable growth.

Mr. Thien said that the water industry is still the main business, but the ecosystem must be expanded to ensure closure. “Biwase is investing heavily in automation and smart management solutions to reduce operating costs and increase labor productivity. Every penny saved from good management will bring many times the profit to the Company,” he said confidently.

Source:v

![[Photo] Parade to celebrate the 50th anniversary of Laos' National Day](/_next/image?url=https%3A%2F%2Fvphoto.vietnam.vn%2Fthumb%2F1200x675%2Fvietnam%2Fresource%2FIMAGE%2F2025%2F12%2F02%2F1764691918289_ndo_br_0-jpg.webp&w=3840&q=75)

![[Photo] Worshiping the Tuyet Son statue - a nearly 400-year-old treasure at Keo Pagoda](/_next/image?url=https%3A%2F%2Fvphoto.vietnam.vn%2Fthumb%2F1200x675%2Fvietnam%2Fresource%2FIMAGE%2F2025%2F12%2F02%2F1764679323086_ndo_br_tempimageomw0hi-4884-jpg.webp&w=3840&q=75)

Comment (0)