After many years of tireless research, with many failures, but when coming to Bao Lam district (Lam Dong), the biotechnology engineer from Binh Duong and his colleagues successfully conquered the high-tech model of cultivating, producing and processing cordyceps (also known as cordyceps) mushrooms. With a closed production process, he and his colleagues have created quality cordyceps products to supply to supermarket systems, restaurants and pharmacies.

|

| Mr. Thanh and the staff in charge of the Cultivation Department check the growth and development of mushrooms. |

* HARD WORK TEST MAN

The Cordyceps mushroom cultivation and production farm with a scale of nearly 2,000 m2, built according to high-tech processes, automatic, closed, modern factory system located in Village 1 (Loc An commune, Bao Lam district) is the startup passion of Mr. Nguyen Tuan Thanh (31 years old) and his university friends. This is also one of the new, typical agricultural development models of Bao Lam district.

In 2016, Mr. Thanh graduated from the Biotechnology Department of Ho Chi Minh City University of Food Technology. As a student and even now, he admits that he is passionate about researching agricultural products. Based on his existing knowledge, after graduating, he invited 3 more friends to join him in renting a space to build a research center and cultivate Cordyceps mushrooms in Ho Chi Minh City. After a while, Mr. Thanh's group decided to move back to his hometown in Ben Cat district (Binh Duong province) to continue pursuing their unfinished dream.

Mr. Thanh confided: “Like many others, when I was a student, I thought that after graduating I would find a stable job to earn an income to cover my living expenses. However, because I was so passionate about research, some of my friends and I decided to choose Cordyceps to try our hand. We pooled capital to rent a space in Ho Chi Minh City to establish the AT Group center and invested in importing embryos from Japan for research. Our goal is to cross-breed imported embryos into our own embryos to proactively source seeds to cultivate and produce Cordyceps sustainably and long-term.”

According to Mr. Thanh, when they were in Ho Chi Minh City, they said they were establishing a research center, but their workplace was only limited to a small space of more than 30 square meters rented from 2 rented rooms. They had to invest capital to rent space and import embryos at a cost of hundreds of millions of VND, but for nearly a year they had no source of income. Due to lack of experience and the unsuitable climate in Ho Chi Minh City, all the embryos imported from Japan were spoiled.

All the investment capital was ruined, but hardships tested people's strength, Mr. Thanh and his friends still did not give up, gave up and decided to move to Ben Cat district (Binh Duong province) to start over. In Binh Duong, they continued to invest more than 300 million VND to import embryos for research and breeding to make their dream come true. In this attempt, Mr. Thanh and his colleagues continued to receive "bitter fruit" when more than half of the embryos were spoiled. However, sweet fruit also came when the remaining embryos were successfully bred and hybridized.

“After many failures, we realized that the weakness we were facing was not being able to control the weather, specifically the temperature and humidity. Therefore, we focused on researching and investing in building factories to solve this problem,” Mr. Thanh shared.

AT Group's products, in addition to being sold fresh, are also freeze-dried and processed into canned extracts supplied to LOTTE supermarket systems, Co.opmart, An Khang pharmacies nationwide and a number of high-end restaurant and hotel systems.

* ACHIEVE SUCCESS

In Binh Duong, after successfully breeding and taking the initiative in the source of embryos, the group invested in building a greenhouse system to cultivate and produce commercial cordyceps mushrooms. After more than 2 years of developing the model, although they had a source of income to reinvest, they realized that the climate and humidity in Binh Duong were not suitable, so expanding the scale would be difficult and costly.

|

| Cordyceps products provided to the market by AT Group Company ensure the best quality standards. |

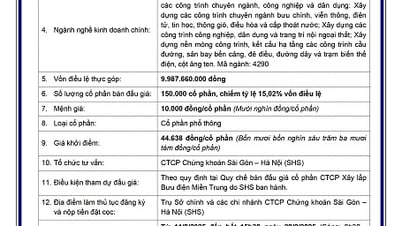

Believing in the direction and passion they are pursuing, after a period of research, Mr. Thanh's group realized that Loc An commune (Bao Lam district) has a suitable climate and soil for the development of cordyceps. In early 2022, they decided to mobilize capital from their families and borrow more to invest more than 15 billion VND to establish AT Group Joint Stock Company and chose Loc An commune to build a mushroom farm with a scale of nearly 2,000 m2. Determining that this is the "heart" of the Company, the cordyceps mushroom production farm was built by Mr. Thanh and his colleagues according to a closed process, applying high technology. In particular, we focus on investing in full infrastructure and equipment such as sterile rooms, cold rooms, tissue culture rooms, cultivation areas and necessary equipment such as shakers, autoclaves, air conditioners, growing media, etc. The mushroom cultivation room in particular is invested in 3 rows with an automatic equipment system that always maintains a stable temperature of 14 - 180C, humidity of 80 - 90%.

In early 2023, based on the synthesis of available raw materials such as brown rice, coconut water, silkworm pupae, potato extract... supplemented with necessary micronutrients, AT Group's cordyceps mushroom farm officially came into operation. Accordingly, on average, every 2-month cycle, the mushroom farm produces about 65,000 boxes of fresh cordyceps mushrooms, equivalent to about 3.5 tons of fresh finished products.

Mr. Nguyen Tuan Thanh said: “Applying 4.0 technology to production helps our mushroom farm not to use growth stimulants in production. In particular, cordyceps mushrooms are naturally antibacterial and have the highest accumulated medicinal content, so they produce the most consistent quality products. Currently, our products, in addition to being sold fresh, are also freeze-dried and processed into canned extracts to supply to LOTTE supermarket systems, Co.opmart, An Khang pharmacies nationwide and a number of high-end restaurant and hotel systems in Ho Chi Minh City. Thereby, bringing in a revenue of about 2 billion VND per month; at the same time, creating stable jobs for more than 20 workers”.

In addition, the company also applies strict production standards of the pharmaceutical industry to the fresh cordyceps cultivation process for export. The products always achieve good quality in terms of both nutritional and food safety indicators through testing. In addition, AT Group also produces spawn to supply to mushroom farms. Following this direction, in the near future, AT Group will expand the production scale of fresh commercial cordyceps to about 150,000 boxes/cycle.

Mr. Nguyen Quang Huy - Deputy Head of the Department of Agriculture of Bao Lam district, commented: “AT Group's Cordyceps mushroom farm is one of the new and typical agricultural production models invested in and developed locally. With the initial success of the mushroom farm, the unit will coordinate to develop it into an OCOP product; at the same time, promote and help people connect and replicate the model to develop the economy and increase income”.

Source

Comment (0)