From policy to action

In 2019, the Ministry of Information and Communications (now the Ministry of Science and Technology) proposed the “Make in Vietnam” strategy with the spirit of “creating in Vietnam, designing in Vietnam, manufacturing in Vietnam”. This is an orientation to help Vietnamese enterprises participate more deeply in the global value chain with their own internal capacity.

Since then, business incubation activities and the creation of self-manufactured products have been continuously carried out. One of the key activities is to create jobs and improve the capacity of Vietnamese workers - those who directly operate, create and complete products.

However, the actual labor productivity of Vietnamese people is still far behind the average of the region in particular and the world in general.

This gap shows that Vietnamese enterprises still need to pay more attention to developing human capital to be self-sufficient in the value chain, helping enterprises improve their competitiveness while giving workers the opportunity to access and develop their expertise; contributing to raising Vietnam's position in the global value chain.

Autonomous production creates sustainable value for the Vietnamese market (Photo: Khoa Huy Hoang).

Innovation becomes the "compass"

Proactively investing and implementing systematic production not only helps businesses master the supply chain but also improves the skills of workers. Therefore, instead of choosing "shortcuts" by importing or assembling, many Vietnamese businesses are still determined to localize production.

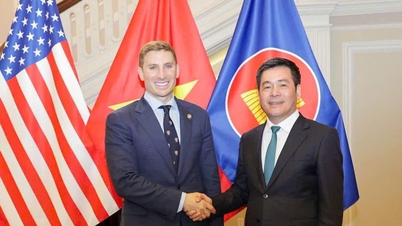

Khoa Huy Hoang is one of the businesses following this development path. Each year, the company supplies the market with about 15 million products manufactured on a production line operated by 100% Vietnamese people.

Not only stopping at technology autonomy, this enterprise also proactively upgraded the factory according to the requirements of the export market. Investing in building a factory that meets Green standards and has Gold Leed certification is Huy Hoang's clear direction towards green, sustainable and energy-saving production.

Currently, the company owns three large-scale factories in Quang Minh Industrial Park ( Hanoi ), with a total area of over 70,000m². The production system is operated in a closed system, strictly following ISO 9001 standards, ensuring the accuracy, safety and aesthetics of each product.

Huy Hoang Lock Factory has achieved Gold Leed certification, meeting international production standards (Photo: Huy Hoang Lock).

The persistence in innovation helps businesses retain their staff for decades. Employees have a modern working environment and stable income, while businesses have a team of engineers and skilled workers to accompany them on the journey to bring Vietnamese products to the world.

Creating sustainable jobs

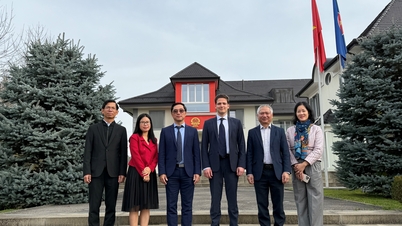

Increasing investment in human capital also creates social value. By innovating technology and developing the distribution system, this enterprise focuses on localizing production, contributing to the formation of a stable employment ecosystem for both direct and indirect workers.

Vietnamese products are increasingly conquering Vietnamese consumers (Photo: Khoa Huy Hoang).

From a green-standard factory to a distribution network covering 34 provinces and cities, Huy Hoang Lock has built a closed production and distribution model, bringing Vietnamese products closer to domestic consumers.

Each agent and each worker is not only a link in the supply chain, but also a "brand ambassador", spreading trust in the quality and reputation of Vietnamese products.

Source: https://dantri.com.vn/kinh-doanh/doanh-nghiep-viet-tu-chu-san-xuat-phat-trien-nang-luc-nguon-nhan-su-20251113193347219.htm

![[Photo] The Government Standing Committee reviews the planning project of the Red River landscape avenue axis](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/11/15/1763197032149_dsc-0163-jpg.webp)

![[Photo] Action for the Community tells stories of enduring journeys – both intimate and great, yet quiet and determined](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/11/15/1763179022035_ai-dai-dieu-5828-jpg.webp)

![[Photo] Exciting contest of skillful red fruit picking and creativity from Son La coffee beans](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/11/15/1763201832979_ndo_bl_3-jpg.webp)

![[Photo] General Secretary To Lam receives Governor of Kanagawa Province (Japan) Kuroiwa Yuji](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/11/15/1763204231089_a1-bnd-7718-5559-jpg.webp)

Comment (0)