|

Bamboo and rattan weaving has long been a traditional cultural beauty in Thach Cau village, Nam Tien commune (Nam Truc). Local people still pass on a familiar song expressing their pride in the craft: "Thach Cau baskets are the best in the world".

|

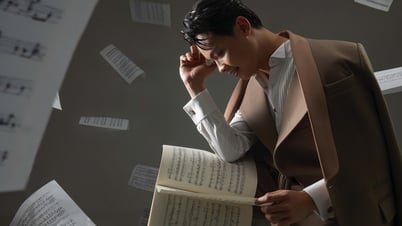

| Splitting bamboo is one of the stages that requires a lot of technique. |

During the prosperous times, children in Thach Cau were already skillful in weaving bamboo from the age of eight. Even though they were over 70 years old, the old men and women were still diligently attached to the craft. That was what helped preserve and develop the traditional craft of Thach Cau. In addition to the main product of baskets, Thach Cau craft village also weaves all kinds of baskets, trays, trays, trays, trays, winnowing nets, winnowing nets, traps (for catching crabs and fish); and traps (for keeping livestock and poultry) from bamboo.

|

| Skillful, meticulous hands of the craftsman. |

Mr. Vu Duy Hien's family is one of the households with a 3-generation tradition of being involved in the profession. There was a time when the whole family of 7-8 people focused on the profession. This year, although he is over 70 years old, Mr. Hien still skillfully uses a knife and saw to split bamboo to weave baskets and baskets. He said that the craft of weaving bamboo and rattan is not too elaborate, anyone can do it, but the experience to create good products must include the stage of selecting raw materials. Bamboo and rattan for weaving must be old. The longer and straighter the bamboo, the better. After being cut, bamboo and rattan must be soaked in a pond for at least a month to prevent termites before being mixed. A skillful person who mixes bamboo must calculate and balance so that no part of the bamboo tree is discarded. The straight segments are used as the main ribs, the top and base are used to make the waistband and ribs... (basket weaving is usually about 70-80cm long; basket weaving is from 1m or more); The top and base are used to make baskets and slats (40-50cm long). The entire process of mixing bamboo and splitting slats must be done continuously and quickly because if left for too long, the bamboo will become “stiff” (dry). The rattan fibers must also be selected from old sections, split thinly, dried, and when tied, soaked in water to soften, peeled again to make them thin…

|

| Bamboo and rattan weaving has long become a cultural beauty of the people of Thach Cau. |

The most technical step is the main bamboo splitting stage. The tool for splitting must be a long-handled knife (about 30-35cm), the knife's back must be thick, and the blade must be sharpened. After splitting, the bamboo is woven into a fence, tightly wedged, "reformed" on all four sides with slatted bamboo, and then brought to the kiln to smoke the straw. The kiln is usually placed in the back garden or the house, about 1m deep, circular, with a diameter equal to the mouth of the basket (about 70cm); the harvested straw is kept separately in a dry place, before smoking, it must be chopped into small pieces about 5cm long. The rim of the basket, after being fixed with a circular mold (diameter equal to the mouth of the kiln), must also be smoked in the kiln to bend it into a round shape. Each batch can smoke from 15-20 bamboo fences and basket rims, smoked continuously for about 20-25 minutes before being brought out to the rim (shape the basket) to "crack" the rattan (tie the rim). The baskets are then patted to be round and even, then turned upside down and smoked again in the oven until they reach the standard “cockroach wing” color, which is both beautiful in color and resistant to termites and durable. Each day, a household with 2-3 workers can make 2-3 finished baskets. Thach Cau baskets are round, tightly woven, and tightly smoky, and are carefully smoked, so their durability and beauty are famous far and wide.

|

| The products are purchased by traders wherever they are made. |

In the past, rattan and bamboo were grown in abundance in the commune, providing an abundant source of raw materials for the village. However, there were times when the products were consumed strongly, and people had to import raw materials from the provinces of Son La, Hoa Binh, Bac Kan, Thai Nguyen, Thanh Hoa, Nghe An, and Ha Tinh to meet production needs. Since the renovation, similar products made of aluminum, plastic, and stainless steel were born, and rattan and bamboo weaving products in Thach Cau gradually lost their position, the craft village declined and disappeared. Workers gradually moved to other jobs with higher incomes. Currently, the whole village has only a few households keeping the craft, so the local source of raw materials is no longer maintained, and craftsmen have to go all the way to Hai Hau district to buy.

|

| In addition to the main product of baskets, Thach Cau people also weave other products: baskets, trays, trays... |

Although modern products have many conveniences, bamboo baskets still have their own value in some farming tasks. Therefore, wherever the products are made, there are traders who come to buy them. In addition to the main product of baskets, to adapt to market demands and take advantage of their experience, the weavers in Thach Cau village also weave other types of trays and trays for drying medicinal herbs.

Currently, those who are still involved in the profession are all old, and each day they try to make only 1 to 2 baskets, but for them, income is not as important as preserving the traditional profession of their ancestors./.

Performed by: Hong Minh - Thanh Hoa

Source

![[Infographic] In 2025, 47 products will achieve national OCOP](https://vphoto.vietnam.vn/thumb/402x226/vietnam/resource/IMAGE/2025/7/16/5d672398b0744db3ab920e05db8e5b7d)

Comment (0)