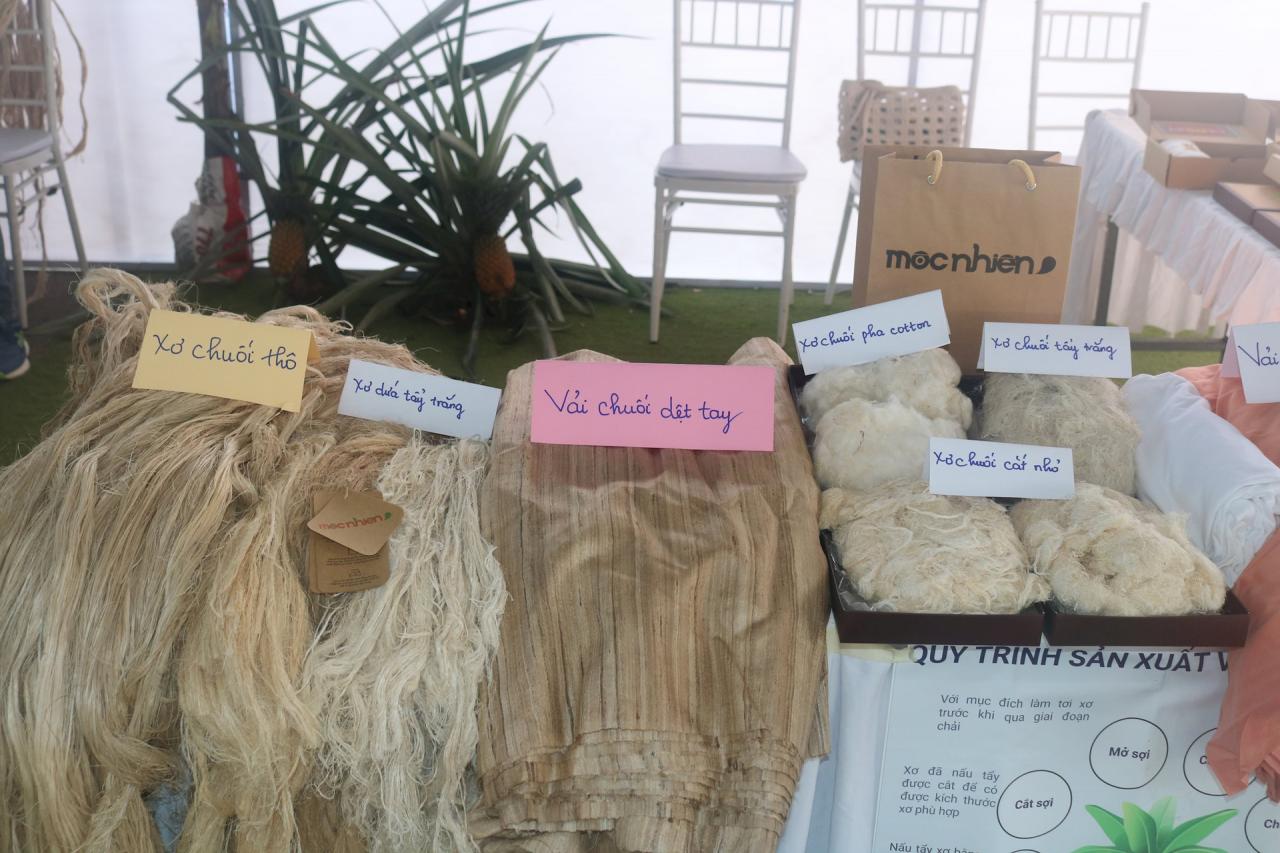

The model for processing fabric from banana stems and stalks, introduced at the Binh Thuan Technology and Equipment Fair 2023 in Phan Thiet city at the end of last year, attracted a large number of delegates and customers who came to visit and learn about it. The unique feature of the soft, thin, and cool fabric is suitable for wearing in prolonged hot weather.

Dr. Pham Thi Hong Phuong, Head of the Chemical Industry Department at Ho Chi Minh City University of Industry (also Head of Ecotech Eco-village, supporting the startup ecosystem for members in Binh Thuan, and co-supporting the province's ongoing science and technology innovation competition), the initiator of the model, said: “Through the model of processing fabric from banana stems and stalks, which is currently being applied, we will soon cooperate with the Binh Thuan Department of Science and Technology to explore raw material sources in the two southern districts of the province, such as Duc Linh and Tanh Linh, to promote the purchase of banana stem and stalk by-products from local farmers. Banana growers will have an additional source of income from these by-products. At the same time, we will explore wild pineapple sources on Phu Quy Island to weave naturally dyed pineapple fabric.”

According to Dr. Pham Thi Hong Phuong, her research team has recently designed and mechanically fabricated machines to strip fibers from banana stems, producing fibers of the standard length and thickness, a feat previously difficult to achieve by hand. One of the biggest drawbacks of banana fiber was its tendency to stiffen when wet, making it difficult to weave into fabric. Many aspiring banana fiber producers have struggled with this. To solve this problem, she guided her team members through a special closed-loop process that altered certain components in the fiber's structure. The cellulose content of the banana fiber was increased to a level sufficient for spinning into yarn. Dr. Hong Phuong successfully completed one of the most challenging steps: producing perfect banana fiber. The next challenge is spinning the fiber into yarn and then weaving it into fabric. A viable approach is to combine banana fibers with other naturally occurring materials. The ratio was carefully calculated to preserve the unique properties of banana fiber while maintaining the quality of the finished fabric.

The head of the banana stem weaving model hopes to transfer this technology to organizations and individuals interested in starting a business in Binh Thuan, as the local banana stem and sheath raw materials are quite abundant, especially in the southern districts of the province. Initially, banana growers in the province can contact Thanh Binh Green Technology Facility in Trang Bom district, Dong Nai province, bordering Binh Thuan (the research and processing facility of Dr. Pham Thi Hong Phuong, which has processed finished banana stem and sheath products for sale to Taiwan), to sell their by-products. In addition, the owner will also introduce the banana stem and sheath fabric products to some coastal resorts in Phan Thiet city for tourists to visit and learn about.

T. KHOA

Source

![[Photo] Prime Minister Pham Minh Chinh presides over a meeting on private sector economic development.](/_next/image?url=https%3A%2F%2Fvphoto.vietnam.vn%2Fthumb%2F1200x675%2Fvietnam%2Fresource%2FIMAGE%2F2025%2F12%2F20%2F1766237501876_thiet-ke-chua-co-ten-40-png.webp&w=3840&q=75)

Comment (0)