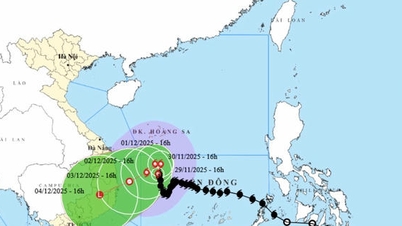

With the typical alum clay material source, the most fertile in the delta, Vinh Long soon formed and strongly developed the brick and tile industry, later red ceramics - a local specialty product. In particular, 1997 marked a major turning point when establishments began to apply circular kilns, using rice husks as fuel, improving efficiency and saving production costs.

Perform the editing step to flatten the surface of red ceramic products

PHOTO: DUY TAN

Since then, the pottery profession has not only created stable jobs for many workers, but also become a place to nurture skilled craftsmen who are devoted to each batch of pottery for life. Among them, there are many women who have quietly "kept the fire" for the craft village with their perseverance and love for the profession.

The red ceramic vases are finished firing.

PHOTO: DUY TAN

Most of the time spent in the red pottery kiln

Each day working at the pottery kiln, female workers earn between 150,000 and 200,000 VND/person. Many have been working in the profession for more than ten years, and some have not left their jobs even though they are old, because they consider working in their hometown a joy.

Ms. Pham Thi Bay has nearly 30 years of experience in making red pottery.

PHOTO: DUY TAN

Ms. Pham Thi Bay (55 years old, living in Thanh Duc Ward, Vinh Long - formerly Long Ho District, Vinh Long) is considered a "kiln keeper", because for nearly 30 years she has spent most of her time in the pottery kiln. "Every day, I spend more time in the pottery kiln than at home. The work is hard, but I work by product, the more I work, the higher my income. Thanks to that, I have been able to raise 2 children to be educated," Ms. Bay shared.

Every day, Mrs. Bay spends more time at the pottery kiln than at home.

PHOTO: DUY TAN

Mrs. Bay is in charge of the "porcelain" stage, editing and smoothing the products after removing the mold. With smooth products, she can make a lot, but with patterned products, she needs more time to meticulously edit every detail.

Batches of ceramic vases ordered by customers as gifts

PHOTO: DUY TAN

Ms. Bui Thi Kim Ngan (37 years old, living in Thanh Duc Ward, Vinh Long) has been working in this profession for more than 10 years. The job not only helps her earn an income to raise her children, but also allows her to flexibly take care of her two children when she takes them to the pottery kiln. "I am in charge of sewing, scraping and making raw product sheds. This job is hard, but I get used to it. If I stay at home and do nothing, I feel restless," Ms. Ngan said.

The dog-shaped ceramic product was polished smooth by Mrs. Bay.

PHOTO: DUY TAN

Ms. Thach Thi Lanh (42 years old, living in Thanh Duc Ward, Vinh Long) is in charge of transporting ceramics into the kiln, one of the arduous steps that requires strength and endurance. "The women are responsible for loading raw ceramics onto the truck, passing them to the male workers to load into the kiln. Although the work is hard, we are used to it and are proud to contribute to producing beautiful batches of ceramics," she shared.

The process of transporting ceramics into the kiln

PHOTO: DUY TAN

Preserving traditional crafts in modern times

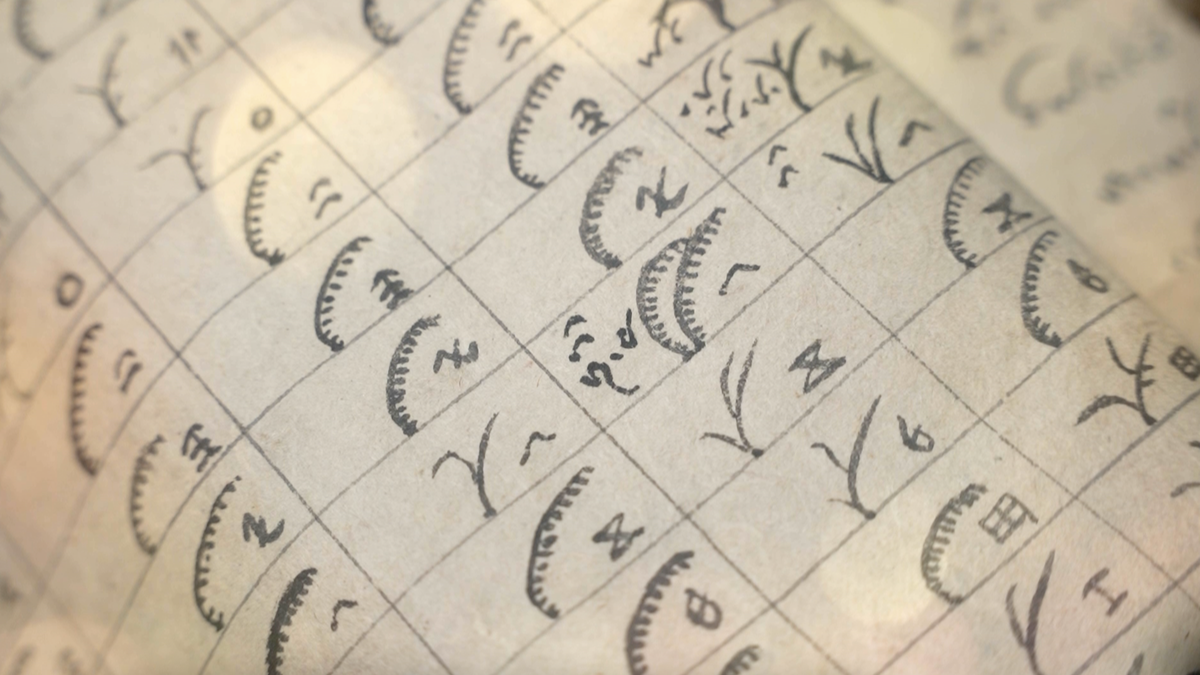

Unlike many traditional pottery villages that use hand-molding, Vinh Long red pottery is produced using plaster molding. After the process of pressing clay into the mold and removing it, the rough product will be edited (xu), smoothing the surface. The most decisive stage is firing the pottery, which requires technique, experience and a delicate sense of temperature, fire and time.

Arrange the products to be passed around and loaded into the oven.

PHOTO: DUY TAN

Thanks to the properties of alum clay, when fired at a temperature of about 900 degrees Celsius for a week, Vinh Long ceramic products have a bright red color, with natural white streaks, a unique feature that cannot be mixed with any other ceramic products.

Vinh Long red pottery is characterized by alum clay, so when fired it will create white streaks.

PHOTO: DUY TAN

Despite the quiet times, the pottery kilns in Vinh Long are still burning day and night. According to Ms. Doan Thi Ngoc Diep, President of the Vinh Long Ceramic and Fine Art Association, in the coming time, the local ceramic industry will focus on developing products with high aesthetic value and lighter weight so that tourists can easily bring them as gifts.

Batches of vases ordered as gifts

PHOTO: DUY TAN

Recently, a number of production facilities have opened their doors to welcome domestic and foreign tourists to visit the pottery making process, experience red pottery molding, etc., thereby contributing to more widely promoting the image of the craft village to international friends.

Source: https://thanhnien.vn/niu-giu-nghe-xua-nhung-bong-hong-nhoc-nhan-ben-lo-gom-do-185250815101902588.htm

Comment (0)