Tien Linh Trading One Member Co., Ltd. is one of two establishments in Bao Yen district that pioneers in producing bio-pellets from by-products of planted forests. The factory is located in Minh Tan commune with a modern processing line, purchasing about 800 tons of raw materials each month such as bark, branches, tops, sawdust, cores, waste boards... from wood processing establishments inside and outside the district. After the stages of chopping, grinding, drying and pressing, the factory produces from 300 to 400 tons of bio-pellets each month.

Not only in the domestic market, Tien Linh Trading Company Limited's pellet products have also reached out to the international market, exported to Japan and Korea - countries with high requirements for quality and environmental standards. The factory price is over 2 million VND/ton, helping businesses maintain sustainable production.

According to Mr. Thoai, bio-pellets are a renewable, environmentally friendly energy source that is being prioritized for development by many countries. These pellets are used for heating systems and industrial furnaces in Europe and Japan; in Vietnam, they are gradually replacing coal in industrial zones... Therefore, the market demand is growing and has a lot of potential.

The pellet production workshop of Tien Linh One Member Co., Ltd. currently has 9 local workers working stably, with an average income of 7 - 10 million VND/person/month. The main job of the workers is to operate machinery, maintain equipment and package products. Mr. Dang Van Thieu (Tan Tien commune) shared: "Previously, I worked in agriculture , with an unstable income. Now I have worked at the workshop for more than 3 years, the job and income are more stable, and I have time to take care of my family."

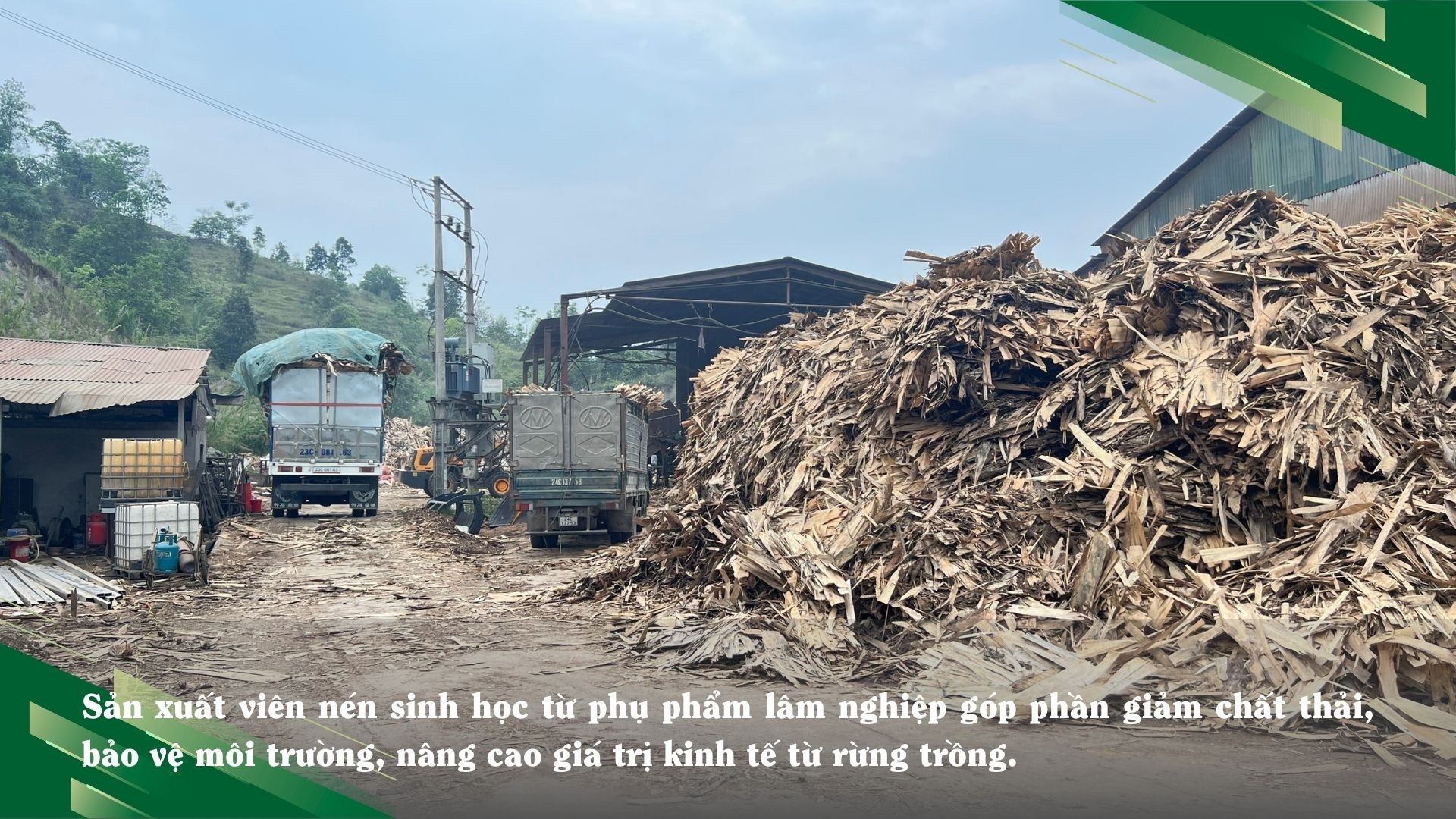

Bao Yen district currently has more than 40,000 hectares of production forests, with more than 40 wood processing facilities in operation. Each year, these facilities consume 25,000 - 30,000 m³ of raw wood, resulting in a large amount of by-products that need to be processed. Previously, most of the by-products such as sawdust, bark, and wood chips were burned, causing air pollution and increasing processing costs for businesses.

Mr. Mai Tien Thang, Director of Thanh Lam Agricultural and Forestry Cooperative (Thuong Ha Commune) said: Every month, the Cooperative processes about 8,000 - 10,000 m³ of raw wood, the amount of waste is up to more than 1,000 tons. Previously, the Cooperative had to hire workers to clean up and destroy by burning, which was both costly and affected the environment. Since having a pellet production facility to purchase by-products, not only does it not cost money to process, but it also has an additional source of income.

Bio-pellet is a clean fuel, has low ash content and emits much lower CO2 than coal. Utilizing by-products to produce pellets helps reduce solid waste in the environment and reduce greenhouse gas emissions.

For the model to be effective in the long term, the relevant departments need to support capital, technology, and market connections and outputs for businesses and cooperatives. If replicated and invested in properly, “green” products from planted forests will not only improve the economic efficiency of forestry but also contribute positively to the sustainable development of the locality.

Source: https://baolaocai.vn/gia-tri-moi-tu-phu-pham-lam-nghiep-post403126.html

Comment (0)