Early in the morning at the Long Thanh airport construction site, large glass panels for the terminal facade began to be installed. Each panel weighs hundreds of kilograms, requiring precise placement on the unitized aluminum frame, in windy, dusty conditions, and an hourly construction schedule. The lotus- inspired terminal with open spaces - many glass panels - makes the requirements for flatness, gaps and aesthetics even more stringent. At the scale of a national key project, a few millimeters of error can result in dozens of square meters of glass having to be replaced. (The lotus design and glass facade of the terminal were officially introduced by ACV).

Adding to the pressure: the basic completion deadline is before the end of 2025, meaning that every item - from the structure to the glass facade - must follow a daily/weekly schedule instead of a monthly one. (The basic completion target of end 2025 is emphasized by the Government and ACV).

If you don't have the right "hands"

Previously, lifting large glass panels with straps or mechanical clamps easily left marks and chipped edges; when the wind blew, “pinning” the glass panels in the right position was almost like… gambling. One slip of the hand could cause cracks and breakage - increasing costs, missing the installation schedule, and “hanging” the assembly line. In the context of the station being topped out and running at full speed, any delay in the facade would drag down the completion of the interior, electromechanical, and acceptance. (The press has reported that the station’s topping out in early 2025 will take place).

Not to mention the scale of the facade: tens of thousands of square meters of unitized/semi-unitized glass and sunshade panels - a number that speaks volumes about the continuous installation volume over many months. (The scope of the phase 1 façade announced by the glass - aluminum contractor: ~28,000 m² unitized, ~6,500 m² semi-unitized, ~9,200 m of panels.

“Vacuum Lifting Equipment”: Sophisticated Hands for Glass Facades

On site, the key solution is a vacuum lifting device specifically for glass and panels: suction "hands" with vacuum cups, tilted 0-90° , rotated 360° , adjusted to the millimeter to bring the glass panels flat - straight - tight:

- Vacuum pump system ( Flexible power source (AC/DC) + backup battery for long work shifts, limiting machine downtime.”

- The adjustable hanging frame helps the facade worker to "mortise and tenon" accurately into the aluminum frame.

- Anti-mark suction cup surface to preserve the aesthetics of the glass panel.

When combined with a mobile gantry crane , hand-crank crane or load-weighing beam , the vacuum lifter turns the “heavy and difficult” stage into a series of standard - fast - safe operations. Thanks to that, the erection team can maintain a high construction pace, catching up with the general milestones of the Long Thanh airport project. (Long Thanh Terminal Phase 1 is expected to be operational by the end of 2025; large-scale glass terminal with open concept).

Short report - A "Long Thanh standard" installation case

08:30, light wind. The 3x1.5m glass panel is firmly attached by the vacuum lifting device, leaving the support. The commander gives the signal, the crane moves forward; the erector waits on the working floor, eyes on the edge of the aluminum frame.

08:32, tilt 85° → 90° , rotate 5-10° , parallel gap. Vacuum indicator light “green”, stable grip.

08:35, the glass panel “touches the lock” of the unitized system; the crew tightens the latch. A short round of applause - another glass “brick” is added to the lotus petal of the future station. (The station’s shape, lotus inspiration and large glass surface are design features).

Why is this solution "right" for Long Thanh?

- Safety with redundancy : dual circuit + warning → reduces the risk of falling at height.

- Speed & precision : tilt - rotate - fine-tune to increase productivity by day/week, ensuring overall progress.

- Facade quality : no marks, no chipped edges; standard joints → uniform aesthetics upon acceptance.

- Adapts to multiple scenarios : from unitized modules to individual glass panels, from indoors to outdoors.

The vacuum lifting equipment package that Tool Range provides is designed for large-format glass façade items: synchronous hanging accessories, weighing beams, connection to cranes/gantry cranes, Vietnamese instruction manuals and on-site operating training - meeting safety and progress criteria in large-scale projects such as Long Thanh .

Contact solution & demo

- Tool Range - vacuum lifting equipment solution for large format glass installation

- Website: https://toolrange.asia • Phone: +84 908 272 234

- Address: Binh Duong Branch, Group 17, Binh Thuan 2 Quarter, Thuan Giao Ward, Ho Chi Minh City

When progress and safety are the “runway” of the project, let “Vacuum Lifting Equipment” be the wings to lift your glass panels - fast, accurate, safe.

Source: https://baocantho.com.vn/thiet-bi-nang-ha-chan-khong-o-long-thanh-phong-su-tu-cong-truong-lap-kinh-nha-ga-a190088.html

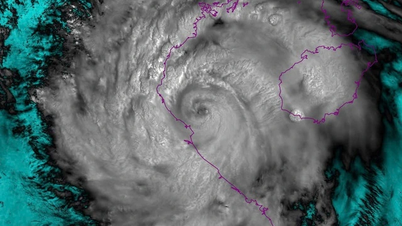

![[Photo] Hanoi: Authorities work hard to overcome the effects of heavy rain](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/8/26/380f98ee36a34e62a9b7894b020112a8)

![[Photo] Multi-colored cultural space at the Exhibition "80 years of the journey of Independence - Freedom - Happiness"](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/8/26/fe69de34803e4ac1bf88ce49813d95d8)

Comment (0)