| Approval of the Planning for exploration, exploitation, processing and use of minerals This day in history July 25: Approval of the Planning for exploration, exploitation and processing of gold and copper ores... until 2025 Establishment of the Council for appraisal of the Planning for exploration, exploitation and processing of minerals |

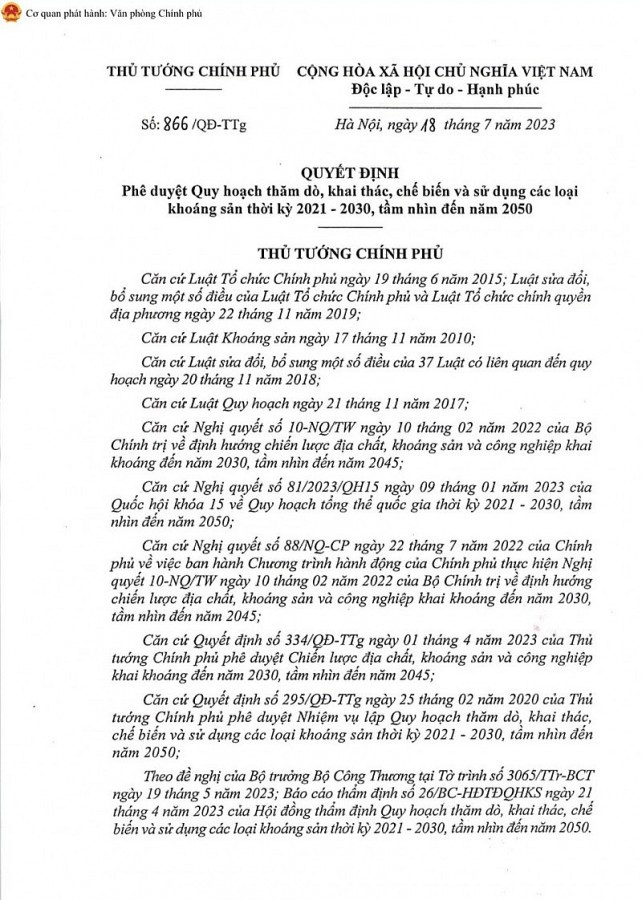

Cong Thuong Newspaper respectfully introduces the full text of Decision No. 866/QD-TTg of the Prime Minister approving the Planning for exploration, exploitation, processing and use of minerals in the period 2021 - 2030, with a vision to 2050.

|

| Decision No. 866/QD-TTg of the Prime Minister approving the Planning for exploration, exploitation, processing and use of minerals for the period 2021 - 2030, with a vision to 2050 |

DECISION

APPROVING THE PLAN FOR EXPLORATION, EXPLOITATION, PROCESSING AND USE OF MINERALS FOR THE PERIOD 2021 - 2030, WITH A VISION TO 2050

PRIME MINISTER

Pursuant to the Law on Organization of the Government dated June 19, 2015; Law amending and supplementing a number of articles of the Law on Organization of the Government and the Law on Organization of Local Government dated November 22, 2019;

Pursuant to the Law on Minerals dated November 17, 2010;

Pursuant to the Law amending and supplementing a number of articles of 37 Laws related to planning dated November 20, 2018;

Pursuant to the Law on Planning dated November 21, 2017;

Pursuant to Resolution No. 10-NQ/TW dated February 10, 2022 of the Politburo on strategic orientations for geology, minerals and mining industry to 2030, with a vision to 2045;

Pursuant to Resolution No. 81/2023/QH15 dated January 9, 2023 of the 15th National Assembly on the National Master Plan for the 2021 - 2030 period, with a vision to 2050;

Pursuant to Resolution No. 88/NQ-CP dated July 22, 2022 of the Government on promulgating the Government's Action Program to implement Resolution No. 10-NQ/TW dated February 10, 2022 of the Politburo on strategic orientations for geology, minerals and mining industry to 2030, with a vision to 2045;

Pursuant to Decision No. 334/QD-TTg dated April 1, 2023 of the Prime Minister approving the Strategy on geology, minerals and mining industry to 2030, with a vision to 2045;

Pursuant to Decision No. 295/QD-TTg dated February 25, 2020 of the Prime Minister approving the Task of developing a Plan for exploration, exploitation, processing and use of minerals for the period 2021-2030, with a vision to 2050;

At the request of the Minister of Industry and Trade in Submission No. 3065/TTr-BCT dated May 19, 2023; Appraisal Report No. 26/BC-HDTĐQHKS dated April 21, 2023 of the Appraisal Council for the Planning of exploration, exploitation, processing and use of minerals for the period 2021 - 2030, with a vision to 2050.

DECISION:

Article 1. Approving the Planning for exploration, exploitation, processing and use of minerals for the period 2021 - 2030, with a vision to 2050, with the following main contents:

A. PLANNING SCOPE AND BOUNDARIES

Scope and boundaries of planning: Planning for exploration, exploitation, processing and use of minerals, except for petroleum minerals, coal, peat, radioactive ores (uranium, thorium, ...), minerals for construction materials and small-scale scattered minerals according to the provisions of the law on minerals. The planning boundary is the area of mineral distribution and mineral processing on the mainland area of the whole country.

B. DEVELOPMENT VIEWPOINTS AND GOALS

I. VIEWPOINT

1. The exploration, exploitation, processing and use of minerals must comply with the national master plan and be compatible with national, sectoral, regional and local plans and in harmony with the requirements of protecting natural landscapes, historical and cultural relics, scenic spots and people's lives.

2. Minerals are limited resources; the exploitation, processing and use of minerals must be carried out on the basis of exploration and comprehensive assessment of factors regarding reserves, resources and quality of minerals, exploitation and processing capacity and usage needs, ensuring savings, efficiency and requirements for national mineral reserves.

3. Strictly, publicly and transparently manage minerals; encourage economic sectors with experience and capacity in mineral processing and exploitation to invest in exploration, exploitation, processing and use of minerals on the basis of respecting market principles, ensuring harmony of interests of the State, people and enterprises; reasonably and effectively balance mineral export and import, prioritizing meeting domestic demand.

4. Developing the exploration, exploitation, processing and use of minerals associated with the application of advanced and modern science and technology in conjunction with the process of transforming the country's economy towards a green economy, circular economy, low-carbon economy and in accordance with international commitments to which Vietnam is a party.

5. For minerals with large, strategic, and important reserves (bauxite, titanium, rare earth, chromite, nickel, gold), licensed mining enterprises must have sufficient capacity and must invest in appropriate processing projects using advanced technology, modern equipment, and sustainable environmental protection.

6. Limit and gradually stop the exploitation of low-reserve, scattered, small-scale mines, concentrate mineral resources from small-scale mines/mining points into mine clusters large enough to invest synchronously in exploration, exploitation, and processing, applying advanced technology and modern equipment.

II. DEVELOPMENT GOALS

1. General objectives

a) Mineral resources are strictly managed, exploited, processed, and used economically and effectively, in line with the development needs of the economy, environmental protection, adaptation to climate change, and the goal of achieving carbon neutrality. Promote investment, form a synchronous and effective mining and processing industry with advanced technology and modern equipment in line with world trends.

b) For minerals with large, strategic, and important reserves (bauxite, titanium, rare earth, chromite, nickel, copper, gold), licensed mining enterprises must have sufficient capacity and must invest in appropriate processing projects using advanced technology, modern equipment, and sustainable environmental protection.

c) Limit and gradually stop the exploitation of low-reserve, scattered, small-scale mines, concentrate mineral resources from small-scale mines/mining points into mine clusters large enough to invest synchronously in exploration, exploitation, and processing, applying advanced technology and modern equipment.

2. Targets for some types of minerals with large, strategic, and important reserves in the period 2021 - 2030

a) Bauxite minerals: Exploration and exploitation must be associated with deep processing (at least to alumina products); investors selected to carry out exploration and exploitation projects must have sufficient capacity to synchronously implement projects from exploration to deep processing, using advanced technology, modern equipment, protecting the environment, especially paying attention to sustainable and effective red mud disposal and treatment plans. Encourage businesses to research and apply new technologies to recycle red mud. New aluminum production projects using electrolysis technology must implement electricity prices according to market mechanisms, in which the use of renewable energy is encouraged.

b) Titanium minerals: Develop the titanium mining and processing industry with a reasonable roadmap and scale suitable for each stage, gradually forming mining - selection technology complexes, titanium mineral processing industrial clusters synchronized with infrastructure. Coastal titanium projects have solutions to ensure water balance for production and people's needs, agricultural development, and aquaculture. Focus on promoting research cooperation, technology transfer, investment in mining and processing of titanium synchronized with deep processing products (pigment, titanium dioxide, titanium metal, high-grade zircon, monazite...).

c) Rare earth minerals: Develop the industry of mining, processing and using rare earth minerals in a synchronous, effective and sustainable manner. For newly licensed enterprises to exploit rare earth minerals, they must be associated with a processing project to produce at least the total of rare earth oxides, hydroxides, and salts with a TREO content of ≥ 95%, encourage production to separate rare earth elements (REO), advanced technology, modern equipment, maximum recovery of accompanying useful minerals, ensuring the environment and radiation safety.

d) Nickel, copper, and gold minerals: Mining of nickel, copper, and gold ores must be accompanied by investment projects for processing in a synchronous, effective, and sustainable manner, maximizing the recovery of associated minerals, and ensuring the environment.

d) Chromite minerals: Chromite mining must have a project to exploit and process to recover maximum accompanying minerals such as nickel, cobalt, and bentonite.

Iron minerals: Research and grant licenses for iron ore exploration and exploitation to units with experience and capacity in processing and exploiting iron ore to process limolite, hematite, poor iron, laterite iron minerals in the Central Highlands, and iron ore nationwide to create quality iron ore products for use in blast furnaces of domestic iron and steel facilities.

e) Apatite minerals: Maximize internal resources and international cooperation in the fields of scientific research, technology transfer for the application of selecting type II, type IV and poor apatite, and producing selective chemicals. Focus on promoting investment in the exploitation, selection and processing of type II and type IV apatite to effectively and economically use resources.

g) For other minerals such as copper, gold, lead, zinc...: Good management of resources, exploitation, processing must use advanced technology and equipment, ensure safety and environment, maximize recovery of mineral resources to meet domestic demand, license exploration, exploitation associated with deep processing address. To synchronize state management, mining projects, investment projects for processing bauxite, titanium, rare earth, chromite, nickel, copper, gold, lead, zinc, iron must be approved by the state management agency for mineral exploitation and processing before licensing.

3. Specific goals

a) Exploration objectives

The exploration objectives for mineral types/groups in the period 2021 - 2030, with a vision to 2050, are summarized in Table 1 below:

Table 1: Exploration objectives for mineral types/groups during the planning period.

| TT number | Mineral type | Unit of measure | Exploration target | |||

| Phase 2021 - 2030 | Phase 2031 - 2050 | |||||

| Project number | Reserves | Project number | Reserves | |||

| 1 | Bauxite | 103 tons of imports | 19 | 1,709,498 | ||

| 2 | Titanium | 103 tons (KVN) | 11 | 36,293 | ||

| 3 | Lead - Zinc | 103 tons of weight | 42 | 1,434 | 7 | 550 |

| 4 | Iron | 103 tons | 35 | 105,095 | 4 | 348,200 |

| 5 | Chromite | 103 tons | 1 | 11,500 | ||

| 6 | Manganese | 103 tons | 7 | 1,750 | ||

| 7 | Tin | 103 tons | 14 | 46.5 | 3 | 4.5 |

| 8 | Tungsten | 103 tons | 8 | 139.3 | ||

| 9 | Antimony | 103 tons | 3 | 25.9 | 1 | 10 |

| 10 | Copper | 103 tons | 15 | 603 | 8 | 229.7 |

| 11 | Nickel | 103 tons | 3 | 409 | 1 | 30 |

| 12 | Molybdenum | 103 tons | 3 | 30 | ||

| 13 | Yellow | Ton | 26 | 101.0 | 2 | 232 |

| 14 | Rare earth | 103 tons TR2O3 | 8 | 983.1 | 1 | 1500 |

| 15 | Apatite | 103 tons | 9 | 255.243 | 1 | 65,000 |

| 16 | White marble | 106 tons of CaCO3 powder | 10 | 147,000 | ||

| 17 | Magnesite | 103 tons | 1 | 6,000 | 1 | 10,000 |

| 18 | Serpentine | 103 tons | 2 | 75,500 | ||

| 19 | Barite | 103 tons | 6 | 3,050 | ||

| 20 | Graphite | 103 tons | 2 | 5,500 | 1 | 1,300 |

| 21 | Fluorite | 103 tons | 1 | 50 | ||

| 22 | Bentonite | 103 tons | 2 | 4,292 | ||

| 23 | Diatomite | 103 tons | 2 | 25,321 | 1 | 3,500 |

| 24 | Talc | 103 tons | 5 | 5.102 | ||

| 25 | Mica | 103 tons | 2 | 69.5 | ||

| 26 | Quartz | 103 tons | 3 | 23,790 | 3 | 28,414 |

| 27 | Quartz | 103 tons | 22 | 11,487 | ||

| 28 | Vermiculite | 103 tons | 1 | 100 | ||

| 29 | Mineral water, hot water | m3/day and night | 149 | 56,990 | 2 | 1,000 |

Phase 2031 - 2050: After the results of the geological and mineral assessment survey for the 2021 - 2030 period are approved, exploration of newly discovered mines will be considered.

b) Objectives for mining and ore selection

- Maintain mining licenses that have been granted in accordance with legal regulations to ensure stability for mineral processing and utilization projects that have been invested in and built.

- Invest in new projects when the project proves that the specific consumer (unit or organization using the project) meets the raw material demand for the country's economic development.

The expected objectives are summarized in Table 2 as follows:

Table 2: Exploitation objectives for minerals in the planning

| TT number | Mineral type | Unit of measure | Exploitation and recruitment goals | |||

| Phase 2021 - 2030 | Phase 2031 - 2050 | |||||

| Number of mines | Output | Number of mines | Output | |||

| 1 | Bauxite | 103 tons imported/year | 18 (3) | 114,500 | 41 | 118,000 |

| 2 | Titanium | 103 tons of KVN/year | 51 (23) | 2,839 | 41 | 3,720 |

| 3 | Lead, zinc | 103 tons imported/year | 60 (13) | 2,387 | 48 | 2,163 |

| 4 | Iron | 103 tons imported/year | 66 (24) | 25,480 | 64 | 33,811 |

| 5 | Chromite | 103 tons imported/year | 2 (0) | 4,700 | 2 | 4,700 |

| 6 | Manganese | 103 tons imported/year | 11 (0) | 352 | 10 | 210 |

| 7 | Tin | 103 tons imported/year | 23 (9) | 3,280 | 19 | 3,026 |

| 8 | Tungsten | 103 tons imported/year | 9 (3) | 5.115 | 7 | 7,390 |

| 9 | Antimony | 103 tons imported/year | 4 (2) | 40 | 3 | 50 |

| 10 | Copper | 103 tons imported/year | 16 (5) | 7,976 | 18 | 9,226 |

| 11 | Nickel | 103 tons imported/year | 6 (3) | 7,800 | 5 | 13,800 |

| 12 | Molybdenum | 103 tons imported/year | 1 (0) | 200 | 1 | 200 |

| 13 | Yellow | 103 tons imported/year | 45 (8) | 1,790 | 39 | 1,967 |

| 14 | Rare earth | 103 tons imported/year | 10 (2) | 2.020 | 13 | 2.112 |

| 15 | Apatite | 103 tons imported/year | 30 (16) | 14,506 | 25 | 16,799 |

| 16 | White marble | |||||

| - Stone cladding | 103 m3/year | 106 (71) | 6940 | 106 | 6840 | |

| - Calcium carbonate powder | 103 tons/year | 39,596 | 39,319 | |||

| 17 | Magnesite | 103 tons imported/year | 2 (0) | 700 | 3 | 1,100 |

| 18 | Serpentine | 103 tons imported/year | 7 (3) | 3,960 | 7 | 3,960 |

| 19 | Barite | 103 tons imported/year | 9 (3) | 624 | 9 | 619 |

| 20 | Graphite | 103 tons imported/year | 7 (4) | 1.151 | 6 | 1.151 |

| 21 | Fluorite | 103 tons imported/year | 5 (3) | 756 | 5 | 756 |

| 22 | Bentonite | 103 tons imported/year | 5 (1) | 426 | 5 | 476 |

| 23 | Diatomite | 103 tons imported/year | 4 (1) | 540 | 4 | 740 |

| 24 | Talc | 103 tons imported/year | 10 (2) | 431 | 10 | 444 |

| 25 | Mica | 103 tons imported/year | 3 (1) | 10 | 3 | 10 |

| 26 | Quartz | 103 tons imported/year | 8 (1) | 1,570 | 8 | 1,820 |

| 27 | Quartz | 103 tons imported/year | 23 (2) | 990 | 20 | 930 |

| 28 | Sericite | 103 tons imported/year | 3 (0) | 172 | 3 | 172 |

| 29 | Vermiculite | 103 tons imported/year | 1 (0) | 5 | 1 | 5 |

| 30 | Mineral water, hot water | m3/day and night | 232 (66) | 79,661 | 234 | 81,961 |

c) Objectives for processing

Focus domestic resources and promote international cooperation to invest in deep processing of minerals such as bauxite, titanium, rare earth, nickel, chromite, etc. Specifically for each type of mineral, see Table 3 below:

Table 3: Objectives of mineral processing in the planning

| TT number | Mineral/product type | Unit of measure | Processing objectives | Quality, requirements | |||

| Project Number | Phase 2021 - 2030 | Project Number | Phase 2031 - 2050 | ||||

| 1 | Bauxite | ||||||

| a | Aluminum | 103 tons/year | 10 (2) | 11,600- 18,650 | 10 | 12,000 - 19,200 | Meet domestic and export standards. Processing plant attached to mining area. |

| b | Aluminum ingot | 106 tons/year | 3 - 5 (1) | 1.2 - 1.5 | 3 - 5 | 2.25 - 2.45 | |

| 2 | Titanium | ||||||

| a | Titanium slag | 103 tons/year | 18 (9) | 853-1,113 | 18 | 1.063 - 1.323 | New projects only meet raw materials for pigment production. |

| b | Ilmenite reduction | 103 tons/year | 2 (1) | 20 - 40 | 2 | 40 - 60 | |

| c | Zircon powder + zircon compound | 103 tons/year | 17 (9) | 302 - 359 | 16 | 362 - 425 | |

| d | Artificial Rutin | 103 tons/year | 2 (0) | 60 - 70 | 2 | 100 - 110 | |

| e | Pigment | 103 tons/year | 6 (2) | 350 - 420 | 6 | 370 - 500 | |

| f | Titanium sponge/titanium metal | 103 tons/year | 2 (0) | 10 - 15 | 2 | 15 - 25 | |

| g | Ferrotitan | 103 tons/year | 2 (0) | 20 - 30 | 2 | 20 - 30 | |

| 3 | Lead, zinc | 103 tons KL/year | 27 (16) | 380 | 27 | 402.5 | |

| 4 | Chromite (Ferrocrom) | 103 tons/year | 2 (2) | 90 | 2 | 90 | High carbon ferrochrome, average Cr content >54% Cr |

| 5 | Manganese (ferromanganese, silicomanganese) | 103 tons/year | 13 (13) | 356 | 12 | 406 | Meet domestic standards |

| 6 | Tin | Tons KL/year | 6 (6) | 3400 | 6 | 3400 | |

| 7 | Tungsten | Tons of products/year | 3 (3) | 13,500 | 3 | 13,500 | (APT, BTO; YTO) |

| 8 | Antimony | Tons KL/year | 3 (3) | 3,300 | 3 | 3,300 | |

| 9 | Copper | Tons/year | 11 (9) | 110,000 | 11 | 110,000 | Copper ingot |

| 10 | Nickel | Tons/year | 2 (0) | 27 - 48 | 2(0) | 42 - 78 | Nickel metal |

| 11 | Molybdenum | Tons/year | 1 (0) | 200 | 1 | 400 | Production of (NH4)2MoO4 (or ferromolybdenum refining) |

| 12 | Yellow | kg/year | 8 (6) | 6.146 | 7 | 6,346 | |

| 13 | Rare earth | Tons of REO/year | 7 (1) | 62,500 | 7 | 82,500 | |

| 14 | White marble | ||||||

| a | All kinds of paving stones | 103 m3/year | 43 (43) | 11,000 | 43 | 10,700 | |

| b | Lumps, granules, powders | 103 tons/year | 58 (52) | 9,461 | 58 | 9,684 | |

| 15 | Alkaline calcined magnesite | 103 tons/year | 1 (0) | 70 | 1 | 70 | |

| 16 | Serpentine (powder) | 103 tons/year | 6 (3) | 3,950 | 6 | 3,950 | |

| 17 | Barite | 103 tons/year | 10 (7) | 292 | 10 | 392 | BaSO4 powder ≥ 95% |

| 18 | Graphite | 103 tons/year | 5 (1) | 110 | 5 | 111 | C > 80% |

| 19 | Fluorite | 103 tons/year | 4 (1) | 256 | 4 | 460 | CaF2 > 80% |

| 20 | Bentonite | 103 tons/year | 5 (2) | 165 | 5 | 260 | |

| 21 | Diatomite | 103 tons/year | 3 (2) | 143 | 3 | 350 | |

| 22 | Talc (powder) | 103 tons/year | 5 (1) | 380 | 5 | 460 | |

| 23 | Mica | Tons/year | 4 (4) | 1,700 | 2 | 1,500 | |

| 24 | Quartz | 103 tons/year | 9 (6) | 730 | 9 | 1,040 | |

| 25 | Quartz | 103 tons/year | 10 (4) | 1,454 | 10 | 1,454 | |

| 26 | Sericite | 103 tons/year | 2 (1) | 138 | 2 | 146 | |

| 27 | Mineral water, NKN | Serving the needs of bottled mineral water and resort tourism |

C. PLANNING FOR DEVELOPMENT OF MINERALS

I. RESOURCES

Resources and resource reserves mobilized in the planning period up to 2030, with a vision to 2050, are summarized in Table 4 below (details in Appendix I attached):

Table 4: Reserves and resources of various minerals mobilized in the Planning period

| STT | Mineral type | Unit of measure | Reserves | Resources and forecast resources | Total |

| 1 | Bauxite | 103 tons of imports | 3,084,674 | 6,465,328 | 9,549,419 |

| 2 | Titanium - Ilmenite | 103 tons of KVN | 109,053 | 502.301 | 611,354 |

| Zircon | 82,426 | ||||

| 3 | Lead, zinc | Ton | 865.190 | 4,943,816 | 5,809,006 |

| 4 | Iron | 103 tons of imports | 491,282 | 663,248 | 1,152,365 |

| 5 | Chromite | 103 tons of Cr2O3 | 14,484 | 7,288 | 21,773 |

| 6 | Manganese | 103 tons of weight | 3,989 | 6,779 | 10,769 |

| 7 | Tin | Tons KL | 23,251 | 125,198 | 148,449 |

| 8 | Tungsten | Tons KL | 172,908 | 136,499 | 309,407 |

| 9 | Antimony | Tons KL | 54,375 | 90,501 | 144,876 |

| 10 | Copper | Tons KL | 432,106 | 1,098,520 | 1,530,626 |

| 11 | Nickel | 103 tons of weight | 611.8 | 3,454.5 | 4,066.4 |

| 12 | Molybdenum | Ton | 7,400 | 21,000 | 28,400 |

| 13 | Yellow | Kg | 75,012.7 | 124,613 | 199,626 |

| 14 | Gemstone | Kg | 229 | 631 | 860 |

| 15 | Rare earth | Tons of TR2O3 | 3,472,347 | 16,349,207 | 19,821,554 |

| 16 | Apatite | 103 tons of imports | 126,247 | 1,854,257 | 1,960,126 |

| 17 | White marble | 103 tons | 1,684,905 | 2,899,892 | 4,664,798 |

| 18 | Magnesite | 103 tons | 23,575 | 71,434 | 95,010 |

| 19 | Serpentine | 103 tons | 32,342 | 67,079 | 99,421 |

| 20 | Barite | 103 tons | 17,321 | 5,615 | 22,936 |

| 21 | Graphite | 103 tons | 9,715 | 21,670 | 33,243 |

| 22 | Fluorite | 103 tons | 16,035 | 4,038 | 20,074 |

| 23 | Bentonite | 103 tons | 15,401 | 114,418 | 129,819 |

| 24 | Diatomite | 103 tons | 566 | 302,656 | 303,222 |

| 25 | Talc | 103 tons | 1,061 | 8,700 | 9,761 |

| 26 | Mica | 103 tons | 70.5 | 370 | 440 |

| 27 | Pyrite | 103 tons | 18,187 | 34,759 | 52,946 |

| 28 | Quartz | 103 tons | 12,848 | 157,954 | 170,801 |

| 29 | Quartz | 103 tons | 4,173 | 20,229 | 24,403 |

| 30 | Silymarin | 103 tons | 218 | 5,933 | 6.151 |

| 31 | Sericite | 103 tons | 2,816 | 2.108 | 4,924 |

| 32 | Vermicilit | 103 tons | 3,807 | 3,807 | |

| 33 | Mineral water | m3/day and night | ≈ 90,000 | ≈ 90,000 |

II. PLANNING FOR EXPLORATION, EXPLOITATION AND PROCESSING OF MINERALS

1. Bauxite minerals

Exploring and exploiting bauxite minerals, producing alumina and aluminum metal in sync with developing transport infrastructure, seaports, electricity and water supply, ensuring the environment and preserving biodiversity suitable for each specific stage; ensuring security and national defense, preserving national cultural identity, and protecting the ecology of the Central Highlands.

a) Exploration

- Period up to 2030: implement 19 projects in Lang Son (1), Dak Nong (7), Lam Dong (8); Binh Phuoc (2); Gia Lai (1) with the target reserve reaching ≈ 1,709 million tons of raw ore.

- Period after 2031 - 2050: after the results of geological investigation and assessment in prospective areas in the period of 2021 - 2030 are approved, exploration of newly discovered mines will be considered.

Details of bauxite mineral exploration projects are in Appendix II.1 attached.

b) Exploitation

- Period up to 2030: Maintain the design capacity of existing mines; expand and increase the capacity of Tay Tan Rai mine and Nhan Co mine; invest in new mining projects in: Dak Nong (4 - 5), Lam Dong (2 - 3), Binh Phuoc (1), Gia Lai (1). Total mining capacity up to 2030: 68,150 - 112,200 million tons of raw materials/year.

Invest in 3 new bauxite mining and processing projects in the Northern region: Lang Son (1); Cao Bang (2) with a total capacity of 1,550,000 - 2,250,000 tons of raw ore/year.

For bauxite mines in the Central Highlands (near densely populated areas), consider early exploration and licensing to maximize mineral resource recovery and allow conversion of land use purposes to serve socio-economic development...

For low-quality bauxite mines in the Northern region, maximize mineral resource recovery, improve the quality of cultivated land, serve domestic needs and export with permission from competent authorities as prescribed by law.

- After 2030: Maintain the design capacity of existing mines, invest in new mining projects in Dak Nong, Lam Dong, Binh Phuoc, Kon Tum, etc. to supply bauxite concentrate for invested alumina plant projects and expansion projects when needed. Total expected mining capacity by 2050: 72.3 - 118.0 million tons of raw materials/year. In addition, the licensing of mining in newly explored areas in the period 2031 - 2050 will be considered when proposed by investors.

Details of bauxite mining projects are in Appendix III.1 attached.

c) Processing

- Period to 2030:

(1) Alumina production: Investing in increasing the capacity of 2 alumina factories Tan Rai - Lam Dong and Nhan Co - Dak Nong from 650,000 tons/year to about 2,000,000 tons/year (divided into 02 phases: phase 1 increases capacity to 800,000 tons of alumina/year; phase 2 invests in expansion with a capacity of 1,200,000 tons of alumina/year).

New investment in alumina production projects in Dak Nong (4), Lam Dong (2), Binh Phuoc (1), Gia Lai (1) with a minimum capacity of 1,000,000 tons of alumina/year/project or more. New investment projects in alumina production must use advanced technology, in which red mud treatment technology must use dry disposal method, ensuring the environment and encouraging projects to produce construction materials from red mud. The location chosen by the investor and locality is suitable for red mud dumping, near the mine selection area.

Total capacity by 2030: 11,600 - 18,650 thousand tons of aluminum/year.

(2) Aluminum metal production: Complete the pilot project of Dak Nong Aluminum Electrolysis Plant with a capacity of 300,000 tons of aluminum ingots/year, expanding to 450,000 tons of aluminum ingots/year. Invest in new aluminum metal production projects in Dak Nong, Lam Dong, Binh Phuoc and provinces with adequate energy sources. Total capacity by 2030: 1,200,000 - 1,500,000 tons of aluminum ingots/year.

The locations of the factories can be located in provinces with raw material and energy sources. The new aluminum electrolysis plant must follow the market mechanism, encourage investment in renewable energy projects to ensure part of the energy in the exploited bauxite mines and produce aluminum processed products, develop mechanical engineering and supporting industries and be consistent with the content of Decision No. 09/QD-TTg dated February 11, 2023 of the Prime Minister on promulgating the Action Plan to implement Conclusion No. 31-KL/TW dated March 7, 2022 of the Politburo on the development orientation of the bauxite - alumina - aluminum industry until 2030, with a vision to 2045.

- Phase 2031 - 2050:

(1) Alumina production: Maintain design capacity and invest in expanding capacity of existing factories.

Total expected capacity: 12,000 - 19,200 thousand tons of aluminum/year.

(2) Aluminum metal production: Maintain the capacity of Dak Nong aluminum electrolysis plant; invest in new aluminum metal production projects associated with self-sufficiency in raw materials and fuel; encourage investment in renewable energy projects in exploited bauxite mines. The location and specific projects are decided by investors based on economic efficiency.

Total expected capacity: 2,250,000 ÷ 2,450,000 tons of aluminum ingots/year.

Details of bauxite mineral processing projects are in Appendix IV.1 attached.

2. Titanium minerals

The licensing of new exploration and exploitation must be linked to processing and production of pigments; investors selected to implement new exploitation projects must have sufficient capacity to synchronously implement projects from exploitation to processing and production of pigments, using advanced technology, modern equipment, and protecting the environment.

a) Exploration

- Period up to 2030: Complete licensed exploration projects in Thai Nguyen (2), Quang Binh (3); conduct new exploration projects in Thai Nguyen (3), Quang Tri (3); Binh Thuan (2) with the exploration target of reaching about 36,200,000 tons of heavy minerals.

- Phase 2031 - 2050: New exploration after receiving results of geological and mineral investigation and assessment in phase 2021 - 2030.

Details of titanium mineral exploration projects are in Appendix II.2 attached.

b) Exploitation

- Period 2021 - 2030: Maintain the output of licensed mines (23 mines; total licensed capacity ≈ 1,450,000 tons of KVN/year), license ≈ 32 new mines in the provinces of Thai Nguyen (5), Ha Tinh (1), Quang Binh (3); Quang Tri (4), Binh Thuan (13). Total capacity ≈ 2,759,000 tons of KVN/year.

- Phase 2031 - 2050: Maintain production at licensed mines and increase capacity at Luong Son I, Luong Son II, Luong Son III mines. Total capacity in phase 2021 - 2050 is expected to reach ≈ 3,634,000 tons of KVN/year.

Details of titanium mineral exploitation projects are in Appendix III.2 attached.

c) Processing

- Period to 2030:

Maintain existing processing projects with total capacity: titanium slag ≈ 319,000 tons/year with 9 invested projects; reduced ilmenite ≈ 20,000 tons/year with 01 invested project; zircon powder + zircon compounds of all kinds ≈ 154,500 tons/year with 10 invested projects.

New investment in processing projects:

(1) Titanium slag: New investment in 7 - 9 projects with total capacity of ≈ 770,000 tons/year; New projects are only licensed to serve pigment production and other industries. Locations are selected appropriately by investors and localities.

(2) Reduced Ilmenite: Invest in 01 new project with expected output of 20,000 - 40,000 tons/year.

(3) Zircon powder, zircon compounds and other products from zircon: New investment or expansion of 4 - 5 processing projects with a total capacity of ≈ 230,000 tons/year;

(4) Pigment: Invest in 3 - 4 new processing projects with total capacity: 320,000 - 450,000 tons/year; locations are selected appropriately by investors and localities.

(5) Artificial Rutin: Invest in 1 - 2 new production projects with a total capacity of 60,000 - 70,000 tons/year.

(6) Sponge titanium/metal titanium: Invest in 1 - 2 new projects with capacity of 10,000 - 15,000 tons/year;

(7) Ferrotitan: Invest in building 1 - 2 new factories with total capacity of 20,000 - 25,000 tons/year.

(8) Monazite: Invest in a new monazite processing plant with a capacity of 10,000 - 15,000 tons/year to process monazite recovered from the ilmenite ore selection process.

In case of eliminating the exploitation of titanium mines in Ninh Thuan, the accompanying titanium processing projects in Ninh Thuan will be simultaneously eliminated.

- Phase 2031 - 2050:

Maintain licensed projects and grant new projects to ensure design capacity with products and total output as follows:

(1) Titanium slag: ≈ 1,323,000 tons/year.

(2) Reduced Ilmenite: maintain project capacity of 40,000 - 60,000 tons/year.

(3) Zircon powder, zircon compounds and other products from zircon: With a total capacity of ≈ 450,000 tons/year;

(4) Artificial rutile: processing projects with total capacity: ≈ 110,000 tons/year.

(5) Pigment production: Maintain and increase the capacity of existing projects with a total expected capacity of 400,000 - 500,000 tons/year.

(6) Sponge titanium/metal titanium: Maintain existing projects, can invest in expansion or new additions (if there is a market) and investors from 1 - 2 projects. Total expected capacity is 15,000 - 25,000 tons/year.

(7) Ferrotitan: Maintain factory output and consider granting new licenses for 1-2 projects with a capacity of 15,000-25,000 tons/year when investors register to implement.

(8) Monazite: Maintain the invested monazite processing plant and expand the area in need with a capacity of 15,000 - 20,000 tons/year to process monazite recovered from the ilmenite ore selection process.

Details of titanium processing projects are in Appendix IV.2 attached.

3. Lead and zinc minerals

a) Exploration

- Period to 2030:

+ Complete licensed exploration projects in the previous phase of 9 projects with the target reserve of 450,000 ÷ 500,000 tons of lead and zinc metal.

+ Granted 34 new exploration projects in the provinces including: Tuyen Quang (5); Bac Kan (18); Lao Cai (3); Yen Bai (2); Dien Bien (2); Thai Nguyen (3); Quang Binh (1) with the target of reaching reserves of 1,000,000 ÷ 1,050,000 tons of lead-zinc metal reserves.

-Phase 2031-2050: additional exploration to upgrade reserves, deep exploration of existing mines and licensing of new exploration from 8 ÷ 10 mines with the target reserve of ≈ 555,000 tons of lead-zinc metal reserves.

Details of lead and zinc mineral exploration projects are in Appendix II.3 attached.

b) Exploitation

- Period up to 2030: Maintain production of licensed projects (12 mines, total output ≈ 700,000 tons of ore/year).

New investment projects in the provinces: Cao Bang (2); Tuyen Quang (8); Bac Kan (23); Thai Nguyen (3); Lao Cai (3); Yen Bai (3); Dien Bien (3); Quang Binh (1) with a total capacity of ≈ 1,689,000 tons of lead - zinc ore/year to supplement output for mines with expired licenses.

- Phase 2031 - 2050: Maintain production of licensed projects, invest in 5 - 10 new projects with a total capacity of ≈ 2,163,000 tons of lead-zinc ore/year.

Details of lead-zinc mining projects are in Appendix III.3 attached.

c) Processing

- Period to 2030:

+ Maintain the operation of invested projects in the provinces of Cao Bang; Ha Giang; Tuyen Quang; Bac Kan; Thai Nguyen, ... with a total processing capacity of ≈ 215,000 tons of lead - zinc metal/year.

+ Complete licensed projects: Investment project to build Yen Bai multi-ferrous metal factory with capacity of 40,000 tons/year; Lead metal smelting factory in Bac Kan with capacity of 20,000 tons/year; Nam Quang - Ha Giang lead-zinc factory with capacity of 10,000 tons/year.

+ Invest in new lead-zinc smelting factories in Cao Bang (1); Tuyen Quang (2), Bac Kan (3); Thai Nguyen (2); Yen Bai (2) with a total capacity of ≈ 165,000 tons of metal/year.

- Phase 2031 - 2050: Maintain the operation of licensed projects, only consider granting new licenses or increasing the capacity of projects when the source of raw materials for the project can be proven.

Details of processing projects are in Appendix IV.3 attached.

4. Iron minerals

a) Exploration

- Period to 2030:

+ Complete exploration projects for Ban Tan, Bang Tuong, Lung Vien mines - Bac Kan; Tan Son - Phu Tho; Lang My 2 - Yen Bai; Nui Khoang, Nui Vom - Quang Ngai; ...

+ New exploration, expanded exploration, upgrading of reserves of projects in: Ha Giang (4); Cao Bang (2); Bac Kan (9); Tuyen Quang (1); Phu Tho (1); Thai Nguyen (3); Dien Bien (1); Lao Cai (3); Yen Bai (9); Ha Tinh (1); Quang Nam (1); Quang Ngai (2); with the target of reaching reserves of - 105,095 million tons of raw materials.

- Phase 2031 - 2050:

New exploration and deep exploration, expanding and upgrading reserves from 5 - 10 projects with the target of reaching reserves of 40 - 50 million tons of raw materials and exploring laterite iron minerals in Chu Se and Duc Co areas of Gia Lai province.

Details of the exploration projects are in Appendix II.4 attached.

b) Exploitation

- Period to 2030:

+ Maintain output and restore production of licensed projects with a total output of 5.0 - 5.5 million tons of raw materials (not including output from the temporarily suspended Thach Khe iron mine with a licensed capacity of 5 million tons/year, only mobilized into the planning when the competent authority decides to continue mining).

+ New investment projects in: Ha Giang (7); Cao Bang (2); Bac Kan (12); Tuyen Quang (1); Phu Tho (2); Lao Cai (5); Yen Bai (9); Hoa Binh (1); Dien Bien (1); Thai Nguyen (4); Thanh Hoa (1); Ha Tinh (3); Quang Ngai (2); Quang Nam (1), with a total newly-granted capacity of 14.8 million tons of raw materials to supply domestic iron and steel projects.

- Phase 2031 - 2050:

Maintain production at mines, invest in new ones, expand and increase the capacity of 20 mines and license a new laterite iron ore mine in Gia Lai with the target of national mining output reaching ≈33.7 million tons of raw materials/year.

Details of iron ore mining projects are in Appendix III.4 attached.

c) Processing

Maintain the operation of existing iron ore processing plants to ensure the supply of iron ore concentrate with Fe content ≥ 60% for domestic steel factories. Build new or renovate and expand iron ore processing plants along with new steel production projects.

5. Chromite minerals

a) Exploration

- Phase 2021 - 2030: Implement the project to evaluate and convert reserves for chromite mineral sand in Tinh Me - An Thuong area, Nong Cong district, Thanh Hoa province.

- Phase 2031 - 2050: Undetermined

Details of chromite mineral exploration projects are in Appendix III.5 attached.

b) Exploitation

- Phase 2021 - 2030:

+ Granting a license to exploit Co Dinh - Thanh Hoa chromite mine with a capacity of ≈ 2,300,000 tons of raw ore/year; prioritizing the mobilization of exploitation in the area near Co Dinh lake first to soon finish exploitation and hand over the land fund for local socio-economic development.

+ Investing in chromite mining in Tinh Me - An Thuong area, Trieu Son and Nong Cong districts with a capacity of ≈ 2,500,000 tons of raw ore/year.

New chromite ore mining and processing projects must recover accompanying minerals including Nickel, Cobalt, and Bentonite.

- Phase 2031 - 2050: Maintain production of licensed mines and consider investing in new exploitation in other areas upon proposal from businesses.

Details of chromite mining projects are in Appendix III.5 attached.

c) Processing

Maintain production of licensed ferrochromium projects, do not license new investments in ferrochromium projects, encourage existing factories to find imported raw materials or convert products to maintain production.

Details of chromite mineral processing projects are in Appendix IV.4 attached.

6. Manganese minerals

a) Exploration

- Period to 2030:

+ Complete licensed exploration projects such as: Trung Thanh, Coc Hec - Ha Giang; Roong Thay - Cao Bang;

+ New exploration of 4 mines in: Tuyen Quang (1); Cao Bang (2); Ha Tinh (1), with the target reserve reaching ≈ 1.75 million tons of raw ore.

- Phase 2031 - 2050: New exploration of other areas when the results of geological and mineral investigation and assessment in the 2021-2030 period are available.

Details of manganese mineral exploration projects are in Appendix II.6 attached.

b) Exploitation

- Period to 2030:

+ Maintain production at mining sites licensed by the Ministry of Natural Resources and Environment and the People's Committees of the provinces.

+ Invest in 9 new mining projects after exploration results in the provinces: Ha Giang (3); Tuyen Quang (1); Cao Bang (5); Ha Tinh (1) with the target of total output reaching 352,000 tons of raw minerals/year.

- Phase 2031 - 2050: Maintain exploitation of licensed mines, make new investments when new exploration projects are added to the planning.

Details of manganese mining projects are in Appendix III.6 attached.

c) Processing

- Phase up to 2030: maintain operations and achieve design capacity of existing factories in Ha Giang, Cao Bang, Tuyen Quang, Bac Kan. Total capacity up to 2030: ≈ 256,000 tons/year; (excluding the Bac Kan iron-manganese smelting project with a capacity of 100,000 tons/year).

- Phase 2031 - 2050: Maintain operations of existing factories. Do not invest in new factories, only expand and increase capacity of factories when raw materials are available. Total capacity: ≈ 306,000 tons/year (excluding the Bac Kan iron - manganese smelting project).

Details of manganese mineral processing projects are in Appendix IV.5 attached.

7. Tin minerals

a) Exploration

- Period to 2030:

+ Complete licensed exploration projects (04 projects): Bu Me - Thanh Hoa; Khe Bun - Ha Tinh; La Vi - Quang Ngai; Tap La - Ninh Thuan.

+ New exploration of 14 mines in the provinces: Ha Giang (1); Cao Bang (1); Tuyen Quang (4); Thai Nguyen (2); Nghe An (1); Lam Dong (3) with the target reserve of ≈ 46,030 tons of tin metal.

- Phase 2031 - 2050: Additional exploration to upgrade reserves and new exploration of 4 - 5 mines with a target reserve of ≈ 4,500 tons of tin metal.

Details of tin mineral exploration projects are in Appendix II.7 attached.

b) Exploitation

- Period to 2030:

Maintain operations of licensed and newly licensed mines, and license expansion to increase mine capacity in the following provinces: Ha Giang (2); Tuyen Quang (5); Cao Bang (1); Thai Nguyen (3); Thanh Hoa (1); Nghe An (5); Quang Ngai (1); Lam Dong (4); Ninh Thuan (1) with a total mining output of ≈ 3,280,000 tons of tin ore/year.

- Phase 2031 - 2050: Maintain annual mining output of ≈ 3,026,000 tons of tin ore/year. Consider licensing new projects when they have been added to the planning.

Details of tin mining projects are in Appendix III.7 attached.

c) Processing

Phase to 2030: Maintain output of existing tin smelting projects, no new investment.

Phase 2031 - 2050: No new construction permits granted, only consider expanding investment in existing projects when raw material sources are proactive.

Details of tin mineral processing projects are in Appendix IV.6 attached;

8. Tungsten mineral

a) Exploration

- Period up to 2030: Complete licensed exploration projects, grant new exploration licenses for 6 mines in the provinces: Ha Giang (1); Tuyen Quang (1); Thai Nguyen (2); Lam Dong (1); Binh Thuan (1) with the target reserve reaching ≈ 140,100 tons of WO3.

- Phase 2031 - 2050: New exploration if there are results of geological and mineral investigation and assessment in the 2021 - 2030 period.

Details of tungsten mineral exploration projects are in Appendix II.8 attached.

b) Exploitation

- Period up to 2030: Maintain the operation of licensed mines and license the exploitation of 8 new mines in the provinces: Ha Giang (1); Tuyen Quang (1); Thai Nguyen (3); Thanh Hoa (1); Lam Dong (1); Binh Thuan (1) which have been surveyed and assessed for reserves with the goal of exploiting ≈ 5,115,000 tons of raw ore/year.

- Phase 2031 - 2050: Maintain operations of licensed mines, grant new licenses when exploration results are available and planning is supplemented, ensuring maintenance of output of ≈ 7,390,000 tons of raw ore/year.

Details of tungsten mining projects are provided in Appendix III.8.

c) Processing

Phase 2021 - 2030 and phase 2031 - 2050: Maintain the output of existing tungsten processing plants, do not grant new investment licenses. Only grant investment licenses for tungsten processing plants when the investor confirms the source of raw materials (after exploration or import).

Details of tungsten mineral processing projects are in Appendix IV.7 attached.

9. Antimony minerals

a) Exploration

- In the period to 2030: Completing the exploration project licensed a few village - Tuyen Quang; new exploration licensing, additional exploration of areas: Ha Giang (1); Tuyen Quang (2); With the target of reserves of 25,930 tons of metal antimon.

- Phase 2031 - 2050: New exploration when there is results of mineral geology and geological evaluation period 2021 - 2030.

Details of Antimon mineral exploration projects in Appendix II.9 attached.

b) Exploitation

- Period up to 2030: Maintain operations of mines such as: Mau Due - Ha Giang; Lang Vai - Tuyen Quang and invest in new mines that have been explored with the target of mining output reaching ≈ 40,000 tons of raw ore/year.

- Phase 2031 - 2050: New investment and maintain 5 mines to ensure the operation of processing plants with an output of ≈ 50,000 tons of original ore/year.

Details of Antimon mining projects in Appendix III.9 attached.

c) Processing

Phase 2021 - 2030 and phase 2031 - 2050: Maintain the output of existing Antimony smelters, do not grant new investment licenses. Only grant investment licenses for Antimony smelters when the investor confirms the source of raw materials (after exploration or import).

Details of antimony mineral processing projects are in Appendix IV.8 attached.

10. Copper minerals

a) Exploration

- Stage to 2030:

+ Complete licensed exploration projects such as: Project to explore additional reserves of the entire deep part of the Sin Quyen copper mine - Lao Cai; Project to explore and upgrade reserves of 333 resource blocks of the deep part of the Vi Kem copper mine, Coc My commune, Bat Xat district - Lao Cai;...

+ New exploration and exploration to 16 projects in Lao Cai localities (7); Yen Bai (1); Son La (2); Cao Bang (2); Thanh Hoa (1); Kon Tum (2) with the goal of reserves ≈ 600,000 tons of copper metal.

- Phase 2031 - 2050: Continue to explore deep, expand the mines under exploitation (10 mines) and new levels when there are detection of mineralization points and geological evaluation surveys with the goal of exploring ≈ 320,000 tons of copper metal.

Details of copper mineral exploration projects in Appendix II.10 attached.

b) Exploitation

- Period up to 2030: Maintain mining output of licensed mines such as Sin Quyen, Ta Phoi, Vi Kem - Lao Cai; Khe Cam, Lang Phat - Yen Bai and recover copper from licensed polymetallic mines such as: Nui Phao, Ban Phuc Nickel; Nickel - Copper Quang Trung commune, Ha Tri - Cao Bang.

New investment, expanded exploitation, increased capacity, and copper ore recovery in the following provinces: Lao Cai (5); Yen Bai (1); Son La (4); Dien Bien (1); Thanh Hoa (1); Cao Bang (2); Kon Tum (3). Total mining output ≈ 11,400,000 tons of copper ore/year.

- Phase 2031 - 2050: Investing and exploiting deep into the mines have been upgraded and invested in 5 new mines in Lao Cai after the results of the exploration.

Details of copper mining projects are in Appendix III.10 attached.

c) Processing

- Stage to 2030: Maintain the operation of licensed projects in: Lao Cai, Yen Bai; Thai Nguyen; Licensing new investment of 02 co -training factories in the area: Tang Loong Industrial Park, Bao Thang District, Lao Cai Province and Kon Ray District, Kon Tum Province. Total processing capacity ≈ 110,000 tons of metal bronze/year.

- Phase 2031 - 2050: Maintain the output of invested copper smelters, do not grant new investment licenses, only grant investment licenses to expand capacity when ensuring raw material sources.

Details of copper mineral processing projects are in Appendix IV.9 attached.

11. Nickel minerals

The licensed mining enterprises must have enough capacity to synchronously invest in processing projects suitable for metal nickel products, use advanced technology, modern equipment, and sustainable environmental protection.

a) Exploration

- Stage to 2030: Completing the Nicken Phuc Mine upgrades and exploration projects; Nickel - Dong Ta Khoa - Son La. New exploration and additional exploration and expansion of areas include: Cao Bang (1); Son La (1) with the target of reserves ≈ 409,000 tons of nickel metal converted.

- Phase 2031 - 2050: Additional exploration of upgrading 1 point of mine in Son La in the previous exploration area with the goal of reserves ≈ 30,000 tons of converted metal metal.

Details of nickel mineral exploration projects are in Appendix II.11 attached.

b) Exploitation

- Period up to 2030: Maintain production of Ban Phuc Nickel mines - Son La; Suoi Cun Nickel - Copper mines - Cao Bang; Ha Tri Nickel - Copper mines - Cao Bang; invest in 4 new mining projects in Cao Bang (1); Son La (3) with the target of mining ≈ 7,200,000 tons of nickel ore/year.

- Phase 2031 - 2050: Maintain the production of licensed mines and grant licenses to expand the upgrade of mining spots with the expiry of the mining license, the total output ≈ 13,200,000 tons of nickel ore/year.

Details of Nicken mining projects in Appendix III.11 attached.

c) Processing

- Period up to 2030: invest in deep processing projects of nickel metal;

- Phase 2031 - 2050: Maintain stable operation of existing processing projects, continue to invest in expanding to raise the capacity of Nicken deep processing projects when ensuring raw materials.

Details of Niken mineral processing projects in Appendix IV. 10 attached.

12. Mineral Mololen minerals

a) Exploration

- Stage to 2030: Completing the licensed Molipden Project in Lao Cai (Kin Tchang Ho).

- Phase 2031 - 2050: Exploring upgrade of 01 mine point in Lao Cai or new exploration of other mines when there is results of surveys and evaluation of mineral geology in the period of 2021 - 2030.

Details of Molipden mineral exploration projects in Appendix II.12 attached.

b) Exploitation

- Period up to 2030: Investing in exploiting molybdenum mines in Kin Tchang Ho, Pa Cheo - Lao Cai.

- Phase 2031 - 2050: Invest in expanding Kin Tchang Ho mine if needed.

Details of molybdenum mining projects are in Appendix III.12 attached.

c) Processing

Invest in building a new factory to produce (NH4)2MoO4 or smelt ferromolybdenum with a capacity of 200 tons/year and increase the capacity in the period after 2030 to 400 tons/year.

Details of molybdenum mineral processing projects are in Appendix IV.11 attached.

13. Gold minerals

a) Exploration

- Stage to 2030:

+ Completing the exploration projects of the mines: Sang Sui - Nam Khong, Pusancap - Area I Lai Chau Province; Late and Huoi Pua plug areas (San village), fertilizer in Nghe An province; area A posted in Quang Tri province; A Pey B area - Thua Thien Hue province; Ma Dao area of Phu Yen province.

+ New exploration, additional exploration to upgrade reserves of mines in the provinces: Ha Giang (2); Tuyen Quang (3); Cao Bang (2); Bac Kan (5); Thai Nguyen (1); Lao Cai (1); Yen Bai (1); Lai Chau (3); Son La (2); Quang Tri (3); Thua Thien Hue (1); Quang Nam (9); Phu Yen (1); with the target reserve reaching ≈ 101 tons of gold.

- Phase 2031 - 2050: Additional exploration, expansion and exploration from 5 mines, new mineralization points detected, with the goal of reserves ≈ 232 tons of metal gold.

Details of gold mineral exploration projects in Appendix II.13 attached.

b) Exploitation

- Stage to 2030: Maintain exploitation to achieve the design capacity of existing mines and maximize golden minerals from bronze mining and mineral mining projects. New investment of mines have been licensed to explore in the previous period and new exploration period 2021 - 2030. The total expected output by 2030 reached ≈ 1,780 million tons of gold ore/year.

- Phase 2031 - 2050: New investment, expand investment to raise the capacity of licensed mines (≈ 10 projects), mines have been explored and maximize gold minerals from multi -metallic mineral exploitation projects.

Details of gold mining projects in Appendix III.13 attached.

c) Processing

- The period to 2030: Maintain existing processing, training and refining projects with a capacity of ≈ 6,146 kg/year. Investing in new gold training facilities in Lai Chau, Tuyen Quang and expanding existing projects to meet the processing needs of exploitation facilities.

- Phase 2031 - 2050: Maintain licensed processing facilities, only invest in expanding, raising the capacity of existing projects. Total output ≈ 6,346 kg of metal gold/year.

Details of gold mineral processing projects in Appendix IV.12 attached.

14. Rare soil minerals

The licensed mining enterprises must have sufficient capacity and must invest in appropriate processing projects (the product is at least the total of oxides, hydroxides, soil salts with rare suspension content ≥ 95%, encourage production to rare soil elements (Ro)), use advanced technology, modern equipment, sustainable environmental protection.

a) Exploration

- The period to 2030: Completing licensed exploration projects at Bac Nam Xe Mine, Nam Nam Xe Lai Chau Province. Upgrade and exploration of exploration of mines licensed to exploit and invest in new exploration at: Lai Chau (7); Lao Cai (2); Yen Bai (1).

- Phase 2031 - 2050: Additional exploration of rare earth mines have granted new exploitation and exploration 1-2 points in Lai Chau and Lao Cai.

Details of rare earth mineral exploration projects in Appendix II.14 attached.

b) Exploitation

- In the period to 2030: Promoting technological search and exploitation market associated with deep processing of rare soil minerals at mines licensed to exploit such as Dong Pao - Lai Chau; Yen Phu - Yen Bai.

Expected investment in new mining projects in Lai Chau (5), Lao Cai (3); Yen Bai (1).

The total output of exploitation is ≈ 2,020,000 tons of original ore/year.

- In the period of 2031 - 2050: Maintaining the operation of existing projects, investing in expanding Dong Pao mining and investing in new 3-4 projects in Lai Chau, Lao Cai, if there is synchronous investor from exploitation, exploitation and processing associated with the product consumption market. The total output of exploitation is ≈ 2,112,000 tons of original ore/year.

Details of rare land mining projects in Appendix III.14 attached.

c) Processing

- Stage to 2030: Completing investment in rare land processing houses in Yen Phu commune, Van Yen district, Yen Bai province.

(1) Total rare soil oxide (suspended): New investment from 3 rare water -processing - processing projects in Lai Chau and Lao Cai provinces with processing products to 2030 (excluding processing output of factories invested from imported raw materials), expected from 20,000 to 60,000 tons/year.

(2) Rare land (Ro): New investment in rare extraction - processing projects in Lai Chau and Lao Cai provinces or locations suitable for rare soil processing products to 2030 (excluding processing output of factories that have invested from imported raw materials), expected from 20,000 to 60,000 tons/year.

- Phase 2031 - 2050: Based on the actual situation, invest in expanding and increasing the capacity of existing projects. Focus on deep processing of rare earth metals.

(1) Total rare soil oxide (suspended): 40,000 - 80,000 tons/year;

(2) Rare land (Ro): 40,000 - 80,000 tons/year;

(3) Rare earth metal: Investing in a new rare metallurgical factory, locations selected by investors with the total capacity of rare earth metals from 7,500 - 10,000 tons/year.

Details of rare soil processing projects in Appendix IV.13 attached.

15. Gemstone minerals

a) Exploration

The development of investment projects for gemstone exploration and exploitation in the period 2021 - 2030, with a vision to 2050, is based on the results of the investigation and assessment approved by the Ministry of Natural Resources and Environment.

b) Exploitation

Maintain exploitation of the project of exploiting the quarry of Doi Ty - Khe Met, Quy Chau, Nghe An province.

16. Apatite minerals

a) Exploration

- In the period to 2030: New exploration of 10 areas with the goal of reserves of ≈ 260 million tons of apatite minerals of all kinds. Priority is given to licensing of deep -down exploration projects with areas that have been exploited in order to maintain production stability.

- Phase 2031 - 2050: Exploration deep with mines already have exploitation licenses.

Details of apatite mineral exploration projects in Appendix II.16 attached.

b) Exploitation

- Stage to 2030:

+ Maintain production for projects granted exploitation licenses (13 mines), licensing 18 new projects with the target of total output of exploitation from 10.1 - 12.0 million tons of apatite ore of all kinds.

+ Exploiting the recovery of type III apatite in the Luu area (13 warehouses) in the form of a rolling output with a total output of ≈ 2,500,000 tons/year to supply existing factories to maintain raw materials for processing projects.

+ Exploiting the recovery of poor type III apatite ore (content

Maintain the operation of existing apatite ore plants and new investment of apatite ore plants under mining projects to meet the processing needs (new investment ore plants have a minimum capacity of 100,000 tons of products/year and up to 300,000 tons of products/year).

- Phase 2031 - 2050: Maintain the operation of licensed and licensed projects from 4-5 projects to ensure the exploitation output ≈ 16.8 million tons of apatite ore of all kinds, focusing mainly on type II apatite.

Details of Apatite mining projects in Appendix III.16 attached.

17. Minerals white floral stone

a) Exploration

- Period up to 2030: Complete licensed exploration projects (7), grant new exploration licenses for mines in Tuyen Quang province (3); Nghe An (2).

- Phase 2031 - 2050: only consider licensing exploration projects when needed.

Details of white marble exploration projects are in Appendix II.17 attached.

b) Exploitation

- Period up to 2030: Maintain the operation of licensed mines with a capacity of ≈ 26 million tons of licensed white stone lumps, granules, and powder; grant new mining licenses to licensed exploration projects with a total output of ≈ 13.3 million tons of white stone lumps, granules, and powder/year and ≈ 2.01 million m3 of paving stones/year.

- Phase 2031 - 2050: Maintain operations of licensed mines, no new mining licenses granted.

Details of white floral mining projects in Appendix III.17 attached.

c) Processing

- Stage to 2030:

+ Maintain the output of licensed stone powder processing factories (54 factories with a capacity of ≈ 7.2 million tons of stone blocks, granules, and powders of all kinds/year). Grant new investment licenses for 6 white stone powder processing projects in: Yen Bai (4); Bac Kan (1), Nghe An (2) with a capacity of ≈ 2.5 million tons of stone blocks, granules, and powders of all kinds/year.

+ Maintain existing stone and construction stone processing factories, focusing on processing products to serve domestic and export needs.

- Phase 2031 - 2050: Maintain operations of licensed projects.

Details of white marble processing projects are in Appendix IV.14 attached.

18. Magnesite mineral

a) Exploration

- Period up to 2030: Complete exploration of licensed mines (Tay Kon Queng and Tay So Ro) in Gia Lai province.

- Phase 2031 - 2050: Exploration, expansion and upgrading of reserves at Tay Kon Queng and Tay So Ro mines in Gia Lai province with the target reserve of ≈ 10 million tons.

Details of the Magnezit exploration projects in Appendix II.18 attached.

b) Exploitation

- Period up to 2030: Granting mining licenses for 02 mines Tay Kon Queng and Tay So Ro in Gia Lai province.

- Phase 2031 - 2050: Maintain operations of 02 licensed mines and invest in expanding the capacity of these 02 mines if conditions permit.

Details of Magnezit exploitation projects in Appendix III.18 attached.

c) Processing

- Phase to 2030: Invest in building 01 factory to produce activated magnesite to serve domestic demand.

- Phase 2031 - 2050: Maintain production of licensed activated magnesite factory.

Details of magnesite processing projects are in Appendix IV.15 attached.

19. Serpentine minerals

a) Exploration

- Stage to 2030:

+ New exploration of mine sites in Te Thang and Te Loi communes, Nong Cong district, Thanh Hoa, with target reserves of ≈ 75 million tons.

+ Exploration of village 5, Phuoc Hiep commune, Phuoc Son district, Quang Nam province, the target of reserves is ≈ 5.5 million tons.

- Phase 2031 - 2050: Not determined.

Details of serpentine exploration projects are in Appendix II.19 attached.

b) Exploitation

- Period up to 2030: Maintain licensed projects such as: Bai Ang - Thanh Hoa; Te Thang - Thanh Hoa; Thuong Ha - Lao Cai with output target of ≈ 660 thousand tons/year.

Licensing new projects at:

- Tat Thang Mine, Tat Thang Commune, Thanh Son District, Phu Tho Province, capacity 50,000 tons/year.

- Te Thang mine, Te Thang commune and Te Loi commune, Nong Cong district, Thanh Hoa province with maximum output of 2,000,000 tons/year.

- Te Thang Mine, Te Thang Commune, Nong Cong District, Thanh Hoa Province with maximum output of 1,000,000 tons/year.

- Mine area of village 5, Phuoc Hiep commune, Phuoc Son district, Quang Nam province, with maximum output of 300,000 tons/year.

- Phase 2031 - 2050: Maintain licensed projects and total output reaches ≈ 3,360,000 tons/year.

Details of serpentine mining projects are in Appendix III.19 attached.

c) Processing

- Phase to 2030: Maintain the operation of the existing Bai Ang serpentine powder grinding plant and invest in expanding or investing in 1-2 new powder grinding projects with the target of total processing capacity reaching 2,950 - 3,950 thousand tons/year. Processed serpentine products are mainly supplied for the production of fused phosphate fertilizer, additives for the steel, ceramic, ceramic tile, tiling and other industries.

- Phase 2031 - 2050: No investment licenses for new projects, only investment to expand and increase capacity of existing projects when needed.

Details of serpentine processing projects are in Appendix IV.16 attached.

20. Barite mineral

a) Exploration

- Period up to 2030: New exploration from 5 projects with target reserves of ≈ 2.5 million tons.

- Phase 2031 - 2050: Not determined.

Details of barite exploration projects are in Appendix II.20 attached.

b) Exploitation

- Period up to 2030: Maintain the operation of licensed projects, grant new exploitation licenses for 6 new projects in Lai Chau (1); Tuyen Quang (2); Cao Bang (3) with a total output target of ≈ 624,000 tons/year.

- Phase 2031 - 2050: Maintain production of licensed projects with total national output of ≈ 620,000 tons/year.

Details of barite mining projects are in Appendix III.20 attached.

c) Processing

- Period up to 2030: Maintain the operation of existing barite powder grinding factories, invest in 3 - 4 new barite powder grinding projects in Cao Bang (1); Lai Chau (1); Lang Son (1) with a total capacity of ≈ 330,000 tons/year.

- Phase 2031 - 2050: Invest in expanding and increasing the capacity of licensed powder grinding projects with the target of reaching ≈ 430,000 tons/year.

Details of barite processing projects are in Appendix IV.17 attached.

21. Graphite minerals

a) Exploration

- Phase to 2030: Complete licensed exploration projects such as: An Binh - Yen Bai; Lang Khoai, Lang Ma, Bong 2 - Lao Cai with the target reserve of ≈ 2.5 million tons. Grant new exploration license in Yen Bai for 01 project in Lien Son area, Lang Thit commune, Van Yen district.

- Phase 2031 - 2050: Additional exploration to upgrade the reserves of Van Yen mine, located in An Binh Dong Cuong commune, Ngoi A commune, and Yen Thai commune, Van Yen district with a target reserve of ≈ 1.3 million tons.

Details of graphite exploration projects are in Appendix II.21 attached.

b) Exploitation

- Period up to 2030: Maintain the operation of licensed projects and license the exploitation of new mines after the exploration and reserve reports have been reported to ensure the total graphite exploitation capacity reaches ≈ 1,151,000 tons/year.

- Phase 2031 - 2050: Maintain operations of licensed mines with total mining output reaching ≈ 1.15 million tons/year.

Details of graphite mining projects are in Appendix III.21 attached.

c) Processing

- Phase up to 2030: Complete investment in licensed factories: Bao Ha graphite; Nam Thi graphite in Lao Cai; invest in 2 - 3 new projects with processing capacity of ≈ 110,000 tons/year of graphite with content > 99% to serve domestic needs.

- Phase 2031 - 2050: Maintain the operation of licensed projects with a total output of ≈ 110,000 tons of graphite with a content of > 99% to serve domestic needs.

Details of graphite processing projects are in Appendix IV.18 attached.

22. Fluorite mineral

Fluorite minerals are currently exploited independently at Xuan Lanh mine (Phu Yen) or as a by-product of other mineral exploitation projects such as Nui Phao polymetallic mine and rare earth mine.

a) Exploration

- Period up to 2030: New exploration in Khau Pha area, Thuong Quan commune, Ngan Son district, Bac Kan province. Exploration target 50,000 tons.

- Phase 2031 - 2050: New exploration when investors propose.

b) Exploitation

- Period up to 2030: Maintain licensed mining projects and recover fluorite from licensed mining projects with an output target of ≈ 450,000 tons/year.

Granting license for new mining project in Khau Pha area, Thuong Quan commune, Ngan Son district, Bac Kan province.

- Phase 2031 - 2050: Maintain mining output and recover fluorite from other mineral exploitation projects, consider new investments when investors propose.

Details of fluorite mining projects are in Appendix III.22 attached.

c) Processing

Phase 2021 - 2030 and after 2030: Maintain the operation of the existing fluorite processing plant and invest in 1 - 2 new projects along with rare earth mining and processing projects. Processing output depends on the mining capacity of other mineral projects, so it is not specifically determined.

New investment in Fluorite processing plant in Thuong Quan commune, Ngan Son district, Bac Kan province with capacity of ≈ 10,000 tons/year.

Details of fluorite processing projects are in Appendix IV.19 attached.

23. Bentonite minerals

a) Exploration

- Period up to 2030: Invest in exploration, expand and upgrade reserves of licensed mining projects to ensure operations for existing projects.

- Phase 2031 - 2050: New exploration as proposed by the investor to meet domestic demand.

Details of bentonite exploration projects are in Appendix II.23 attached.

b) Exploitation

- Period up to 2030: Maintain operations of licensed projects, license 4-5 new projects with output target of ≈ 400,000 tons/year.

- Phase 2031 - 2050: Maintain operations of licensed mines, ensuring total output to meet domestic demand of ≈ 450,000 tons/year.

Details of bentonite mining projects are in Appendix III.23 attached.

c) Processing

- Period up to 2030: Maintain bentonite processing plants in Nha Ne - Binh Thuan; Tam Bo - Lam Dong and grant new investment licenses for 3 - 4 bentonite processing plant projects with a target output of ≈ 165,000 tons of bentonite/year.

- Phase 2031 - 2050: New investment or expansion to increase capacity of bentonite processing plants to meet output of ≈ 260,000 tons/year.

Details of bentonite processing projects are in Appendix IV.20 attached.

24. Diatomite mineral

a) Exploration

- Period up to 2030: grant new exploration licenses or expand exploration of licensed mines such as: Hoa Loc - Phu Yen; Dai Lao - Lam Dong with the target reserve of ≈ 25.3 million tons.

- Phase 2031 - 2050: License to expand exploration of Tuy Duong - Phu Yen mine with target reserves of ≈ 3,500,000 tons.

Details of diatomite exploration projects are in Appendix II.24 attached.

b) Exploitation

- Period up to 2030: Maintain output of licensed projects and license new exploitation from 2 - 3 mines with the target output of ≈ 540,000 tons/year.

- Phase 2031 - 2050: Invest in increasing the mining capacity of licensed mines or licensing new mining from 2 - 3 mines with the target of total output reaching ≈ 740,000 tons/year.

Details of diatomite mining projects are in Appendix III.24 attached.

c) Processing

Only invest in expanding existing diatomite grinding projects or invest in new grinding projects according to mining projects.

Details of diatomite processing projects in Appendix IV.21 attached.

25. Talc minerals

a) Exploration

- Period up to 2030: Exploration and upgrading of reserves of licensed mining sites in the period before 2020 and new exploration from 7 investigated and evaluated mining sites in Phu Tho (2); Hoa Binh (2); Son La (2); Da Nang (1) with the target reserve reaching ≈ 4.3 million tons.

- Phase 2031 - 2050: New exploration of newly discovered mine sites during the mineral geological investigation and assessment process in the 2021 - 2030 period.

Details of talc exploration projects are in Appendix II.25 attached.

b) Exploitation

- Period up to 2030: Maintain output of licensed mining projects such as: Ta Phu - Son La mine; Thu Ngac, Long Coc, Phu Tho province; Tan Minh, Hoa Binh province.

New investment in 09 mining projects that have been licensed for exploration and have approved reserves: Son La (2); Phu Tho (2); Hoa Binh (4); Da Nang (1) with a total capacity of ≈ 410,000 tons/year.

- Phase 2031 - 2050: Maintain output of licensed projects and invest in new exploitation of mines added to the planning with the target of total output reaching ≈ 450,000 tons/year.

Details of Talc exploitation projects in Appendix III.25 attached.

c) Processing

- Invest in building talc grinding plants along with newly licensed mining projects in the period 2021 - 2030 and after 2030.

- Maintain 01 existing factory in Phu Tho and invest in 04 new factories in the provinces of Phu Tho (1); Hoa Binh (1); Son La (1); Da Nang (1).

Details of talc processing projects are in Appendix IV.22 attached.

26. Mica minerals

a) Exploration and exploitation

In the period 2021 - 2030: Invest in new mica exploration and exploitation projects in Ban Mang area, Ban Ria commune, Quang Binh district and Na Chi commune, Xi Man district, Ha Giang province.

Post-2030 period: Undetermined.

b) Processing

Maintain existing mica grinding and selection projects in kaolin and feldspar to ensure capacity of ≈ 1,700 tons/year to supply the domestic market.

Details of mica exploration, exploitation and processing projects are in Appendix II.26; III.26 and IV.23 attached.

27. Pyrit minerals

Currently, there is no domestic demand for Pyrite minerals, so there is no planning. In the immediate future, it is recommended to include it in the national mineral reserve area.

In case an investor proposes exploration, exploitation and processing, it will be considered on a case-by-case basis.

28. Quartzite mineral

a) Exploration

- Period up to 2030: Grant new exploration licenses and upgrade exploration of reserves at 4 new mines in Lao Cai (2); Phu Tho (1); Thai Nguyen (1); with the target reserve reaching ≈ 23.8 million tons.

- Phase 2031 - 2050: Continue to explore and expand licensed mining sites or explore 4 - 5 new mining sites discovered during the mineral geological investigation and assessment process in the 2021 - 2030 period with the target reserve of ≈ 28.4 million tons.

Details of Quarzit probes in Appendix II.28 attached.

b) Exploitation

- Period up to 2030: Maintain the operation of licensed mines such as: Lang Lai - Thai Nguyen; Thuc Luyen (Don Vang) - Phu Tho; Huong Phong - Thua Thien Hue and grant new mining licenses for projects in Lao Cai (2); Thai Nguyen (1); Phu Tho (1); Ha Tinh (1) with the target of total output reaching ≈ 1.57 million tons/year.

- Phase 2031 - 2050: Grant licenses to expand the capacity of licensed projects and grant licenses to exploit 5 - 10 new projects, increasing the total output to ≈ 1.82 million tons/year.

Details of quartzite mining projects are in Appendix III.28 attached.

c) Processing:

Quartz processing (crushing and selection) is invested according to the capacity of licensed mining projects in the period of 2021 - 2030 and after 2030 to meet the needs of economic sectors.

Details of quartz processing projects are in Appendix IV.24 attached.

29. Quartz minerals

a) Exploration

- Period up to 2030: Invest in new exploration from 22 new projects with the target of reaching reserves of ≈ 11.5 million tons in the provinces of Cao Bang (2); Lao Cai (1); Yen Bai (3); Bac Kan (7); Ha Tinh (3); Binh Dinh (3); Phu Yen (2).

- Period 2031 - 2050: Consider investing in expanding, upgrading reserves or investing in new exploration of 5 - 10 newly discovered mines to maintain mining output to serve the needs of the economy.

Details of quartz exploration projects are in Appendix II.29 attached.

b) Exploitation

- Period up to 2030: Maintain licensed projects and grant new mining licenses from 23 mines after exploration and reserve reporting in Cao Bang (2); Lao Cai (2); Yen Bai (4); Bac Kan (7); Ha Tinh (3); Binh Dinh (3); Phu Yen (2) with a total output target of ≈ 1,130,000 tons/year.

- Period 2031 - 2050: Maintain output of ≈ 1,070,000 tons/year, can increase total output higher when the economy has demand.

Details of quartz mining projects are in Appendix III.29 attached.

c) Processing

Quartz processing (crushing and selection) is invested according to the capacity of licensed mining projects in the period of 2021 - 2030 and after 2030 to meet the needs of economic sectors.

Details of quartz processing projects are in Appendix IV.25 attached.

30. Sillimanite mineral

Currently, the country has 03 sillimanite mines identified through geological surveys, 01 mine with identified reserves is the Hung Nhuong graphite mine - Quang Ngai, the remaining 02 mines have not been explored.

During the period 2021 - 2030 and vision 2050, there will be no planning for the exploitation and processing of sillimanite and its inclusion in the national mineral reserve area.

31. Serisite mineral

Maintain the design capacity of the Son Binh serisite mining project, Huong Son district, Ha Tinh province according to the license of the Ministry of Natural Resources and Environment.

New investment in 02 projects for mining and selecting serisite ore in Bac Yen district, Son La province, with total new investment capacity from 70,000 - 130,000 tons/year.

Supplement new planning for exploration and exploitation projects when new mines are discovered and have been investigated, evaluated, and have a market for product consumption.

During the period 2021 - 2030 and vision 2050, maintain exploitation and processing of projects invested before 2030 and invest in projects when new discoveries are made.

Details of sericite mining and processing projects are in Appendix III.29 and IV.26 attached.

32. Vermiculite mineral

Supplement new planning for exploration and exploitation projects when mines are investigated and evaluated as having potential and have a market for product consumption.

During 2021 - 2030 and vision to 2050, the planning of Vermiculite Son Thuy - Tan Thuong, Son Thuy commune, Van Ban district, Lao Cai province.

Details of Vermiculit exploitation projects in Appendix III.30 attached.

33. Mineral water and natural hot water

a) Exploration

- Stage to 2030: New exploration ≈ 150 mines (drill holes) with the goal of exploitation ≈ 56,990m3 mineral water/day - night to serve the needs of resort and drinking water in: Ha Giang (4); Tuyen Quang (5); Lai Chau (21); Son La (1); Peace (12); Dien Bien (6); Hanoi (1); Phu Tho (6); Yen Bai (19); Bac Kan (1); Hung Yen (5); Thai Binh (6); Ninh Binh (2); Thanh Hoa (5); Nghe An (1); Ha Tinh (1); Thua Thien Hue (5); Quang Tri (1); Da Nang (2); Quang Nam (8); Binh Dinh (8); Phu Yen (4); Khanh Hoa (8); Binh Thuan (2); Kon Tum (2); Long An (4); Tien Giang (3), ...

- The period after 2031 - 2050: Depending on the need, it will be licensed when there is a proposal.

Details of the exploration projects are in Appendix II.31 attached.

b) Exploitation

- Period up to 2030: Maintain the operation of 66 licensed mining points (exploitation boreholes) and grant new mining licenses for 166 mining points (exploitation boreholes) with a total exploitation output of ≈ 80,000 m3 of mineral water/day and night.

- Phase 2031 - 2050: Maintain drilling holes nationwide to meet the needs of resort tourism and bottled drinking water. Consider issuing new licenses when needed.

Details of mineral water and natural hot water exploitation projects are in Appendix III.31 attached.

c) Processing: Producing bottled water and exploiting to serve the needs of bathing and resort, not planning processing projects.

III. PLANNING FOR USE OF MINERALS

Exploration planning projects are linked to exploitation planning projects, exploitation projects are planned to provide raw materials for processing projects according to the balance of market demand.

1. For metal minerals: Raw minerals after mining, through selection for enrichment, separation of components (if polymetallic minerals) into refined ore meeting the prescribed standards according to the requirements for each processing technology to supply to projects/processing plants for production into metal products, alloys or intermediate products listed in Table 3 to supply domestic demand and export.

- Gypsum bauxite minerals in the Central Highlands: Exploiting and selecting refined ores to supply alumina factories. Alumina and hydroxide products provide raw materials for aluminum electrolysis plants, other domestic needs and exports. Diaspo bauxite minerals in the Northern provinces are exploited and selected into refined ores to supply grinding stone factories... and the Ministry of Industry and Trade is responsible for considering the export according to the proposal of the People's Committee of the province or city where the mine is located based on the balance of domestic supply and demand.

- For products processed from rare earth ores: Total rare earth (oxide, hydroxide, salt) with TREO content ≥ 95% and separate rare earth oxide (REO) to supply domestic demand and consider for export.