The Ministry of Health proposes new regulations on conditions for granting Certificates of eligibility for cosmetic production facilities.

According to the draft, to be granted a Certificate of eligibility for cosmetic production, a cosmetic production facility must meet the requirements on personnel, factory, production equipment and auxiliary systems, quality management system, etc.

In particular, the personnel conditions must meet the following requirements: Sufficient staff with professional qualifications appropriate to the assigned job position and trained in basic knowledge of CGMP and related professional knowledge; the organizational structure must have a production department and a quality control department managed by different people, independent of each other; the person in charge of production of the facility is a full-time employee of the facility, has a university degree in one of the following majors: Pharmacy, medicine, chemistry, biology, biochemistry, biotechnology or other majors, has been trained in cosmetics production and has worked in cosmetics production for at least 24 months.

In addition, the person in charge of quality assurance is a full-time employee of the facility, has a university degree in one of the following majors: Pharmacy, medicine, chemistry, biology, biochemistry, biotechnology or other majors, has been trained in cosmetic quality management (quality assurance, quality control) and has worked in the field of quality management for at least 24 months.

Production personnel: There are enough workers with specialized knowledge, experience, skills, and capacity to meet the scale and production conditions of the facility and are trained in production operations according to CGMP principles.

Factory conditions

According to the draft, in terms of location and environment, the facility must have enough space to arrange the cosmetic production area, auxiliary areas and be convenient for the production, storage and transportation of cosmetics; the cosmetic production and storage area must not be flooded or stagnant; must not be affected by animals, insects, harmful microorganisms; must not be affected by areas polluted with dust, toxic chemicals and other sources of pollution.

Regarding the design and construction of the production workshop, the production workshop and auxiliary areas must be designed and built with enough space to accommodate the equipment of the cosmetic production line and in accordance with the design function of the facility. The workshop is designed and arranged according to the one-way principle, ensuring production at consecutive locations in a reasonable order consistent with the sequence of operations.

There must be defined areas for the following operations: Receiving raw materials, sampling raw materials, receiving goods and quarantining, storing input raw materials, weighing and supplying raw materials, mixing, storing products awaiting packaging, packaging products, quarantining before shipping, storing finished products, loading and unloading goods, testing room, cleaning equipment.

Wall and ceiling surfaces shall be smooth and easy to maintain. Floors in the preparation area shall have surfaces that are easy to clean and sanitize.

Effective measures must be taken to ensure hygiene and sanitation in the production of cosmetics; to avoid contamination from the surrounding environment and animals.

There must be a clean air treatment system for rooms/areas where raw materials and semi-finished products are in direct contact with the environment (The system has an AHU including primary filters, intermediate filters and HEPA filters).

The warehouse for storing raw materials, packaging and finished products must ensure separation between raw materials, packaging and finished products; have separate areas for storing flammable and explosive substances, highly toxic substances, rejected, recalled and returned raw materials, materials and products, etc.

Conditions on production equipment and auxiliary systems

Regarding equipment, the surface of the equipment that comes into direct contact with the raw materials during the preparation process must not react with or adsorb those raw materials.

Equipment shall not adversely affect product quality through valve leakage, oil leakage, improper adjustment or replacement of parts and shall be easy to clean; equipment shall be designed and arranged for the production of the type of cosmetic product to avoid obstruction and obstruction of the passageway and shall be properly labelled to ensure that products are not mixed or confused with each other.

Water, steam and compressed air or vacuum lines, if installed, shall be easily accessible during operation. These lines shall be clearly labeled.

The ventilation system ensures ventilation for the areas of the facility and is suitable for the requirements of the type of cosmetic production; easy to maintain and clean. The wind direction of the ventilation system must ensure that it does not blow from areas at risk of contamination to clean areas.

The lighting system ensures light to meet production requirements, quality control, product safety; light bulbs must be safely covered with boxes and nets to avoid breakage and ensure that broken pieces do not fall into cosmetics.

The water supply system ensures enough clean water for cosmetic production and must at least meet the national technical standards on drinking water issued by the Minister of Health .

Conditions on Quality Management System

According to the draft, establishments must establish and maintain a quality management system to control the production process to ensure that all products manufactured by the establishment meet the announced quality standards and are safe for users until the expiry date.

Implement and maintain complete records and documents on production, quality control, distribution circulation to trace the history of all product batches and records of all other activities performed at the facility.

All production operations must be carried out according to procedures and instructions. Apply inspection and monitoring measures during the production process to prevent the risk of confusion, contamination, and cross-contamination. Record results immediately when performing operations or immediately after completing the production stage in the file.

There is a testing room separate from the production area to check the quality of raw materials, semi-finished products, and finished products; there is a quality control department to ensure that products are manufactured under appropriate conditions and processes and meet established standards; necessary tests have been performed; raw materials for use and products for sale must be inspected and evaluated by the quality management department to meet the required quality; products must be monitored for stability; there is a production process for each product.

Raw materials and packaging used in cosmetic production must meet the manufacturer's quality standards. Semi-finished products put into production must have quality standards and meet the manufacturer's quality standards.

In case of cosmetic testing under contract, the contract recipient must meet the conditions prescribed by law on providing cosmetic testing services.

The draft clearly states that cosmetic manufacturing establishments that have been granted a Certificate of eligibility for cosmetic manufacturing and are operating under the Certificate of eligibility for cosmetic manufacturing as prescribed in Decree No. 93/2016/ND-CP dated July 1, 2016 of the Government regulating the conditions for cosmetic manufacturing shall comply with the roadmap prescribed in Clause 4, Article 66 of this Decree.

According to the draft, cases of revocation of Certificate of eligibility for cosmetic production facilities include:

1. Cease cosmetic production activities.

2. Not meeting one of the conditions for granting a Certificate of eligibility for cosmetic production as prescribed in Article 14 of this Decree.

3. Certificate of eligibility for cosmetic production facility issued without proper authority or with illegal content.

4. Not operating for 12 consecutive months without notifying the state agency managing cosmetics.

Please read the full draft and give your comments here.

Wisdom

Source: https://baochinhphu.vn/dieu-kien-cap-giay-chung-nhan-co-so-du-dieu-kien-san-xuat-my-pham-102250519112757799.htm

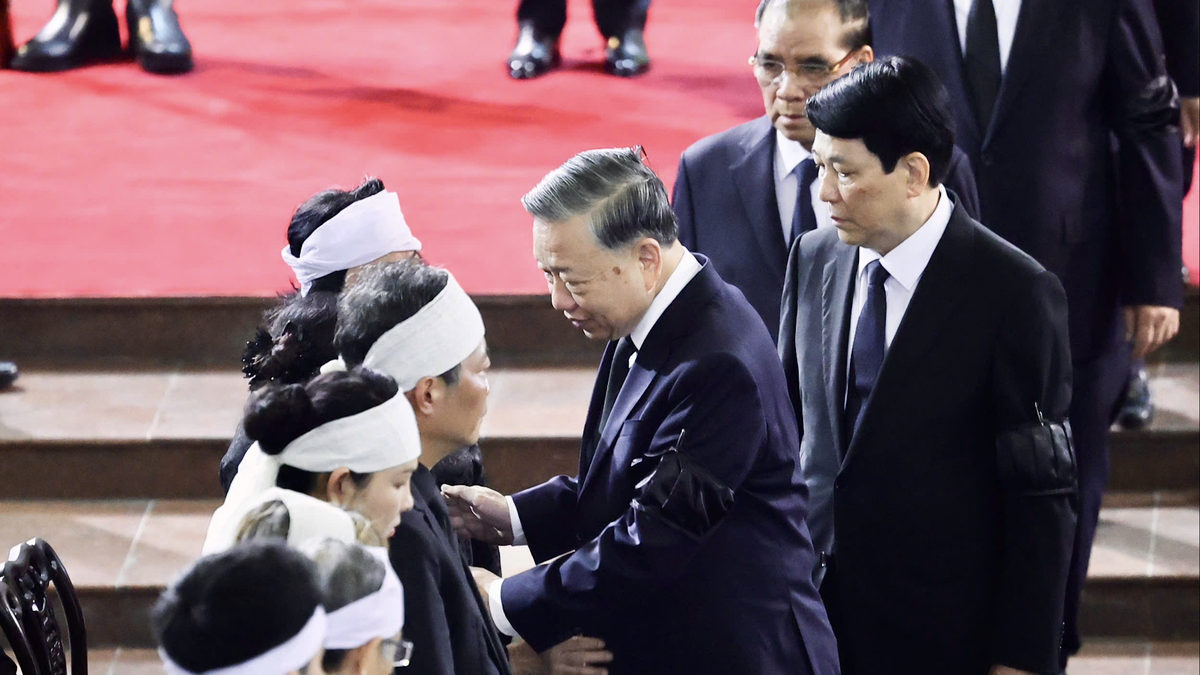

![[Photo] Party and State leaders visit former President Tran Duc Luong](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/24/960db9b19102400e8df68d5a6caadcf6)

![[Photo] Ho Chi Minh City holds funeral for former President Tran Duc Luong](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/24/9c1858ebd3d04170b6cef2e6bcb2019e)

Comment (0)