At the age of 64, Director Nguyen Van Tri still deftly adjusts the precision mechanical equipment worth tens of billions of dong at the factory in District 7 (HCMC). This mechanical factory once made molds to produce hundreds of millions of Colgate toothbrushes, which were sold globally.

But not only toothbrush molds, Lap Phuc Company Limited also specializes in precision mechanics, manufacturing molds for many products and product details of brands such as Tesla, GM (General Motors), Suzuki, Panasonic, Sanyo...

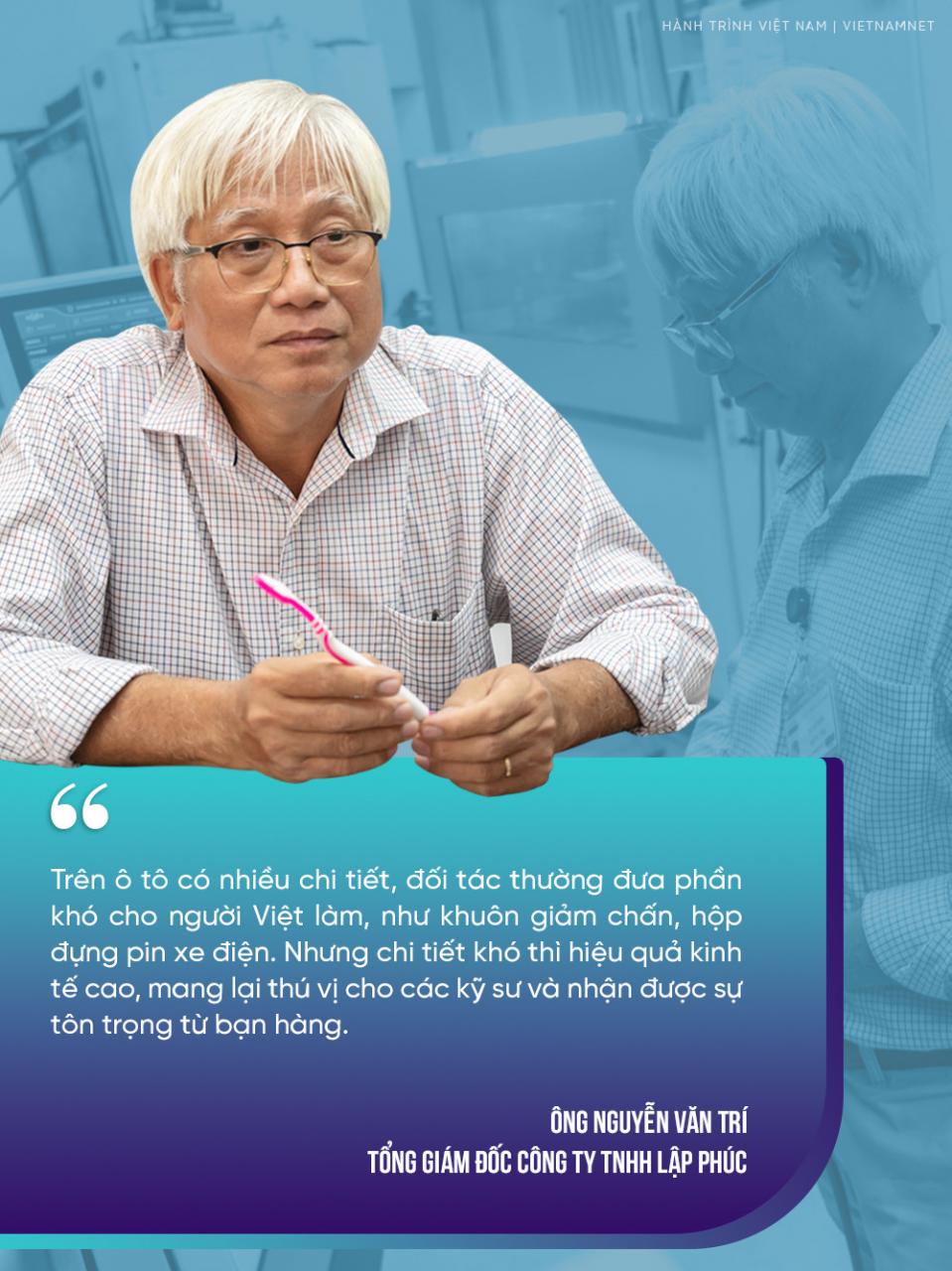

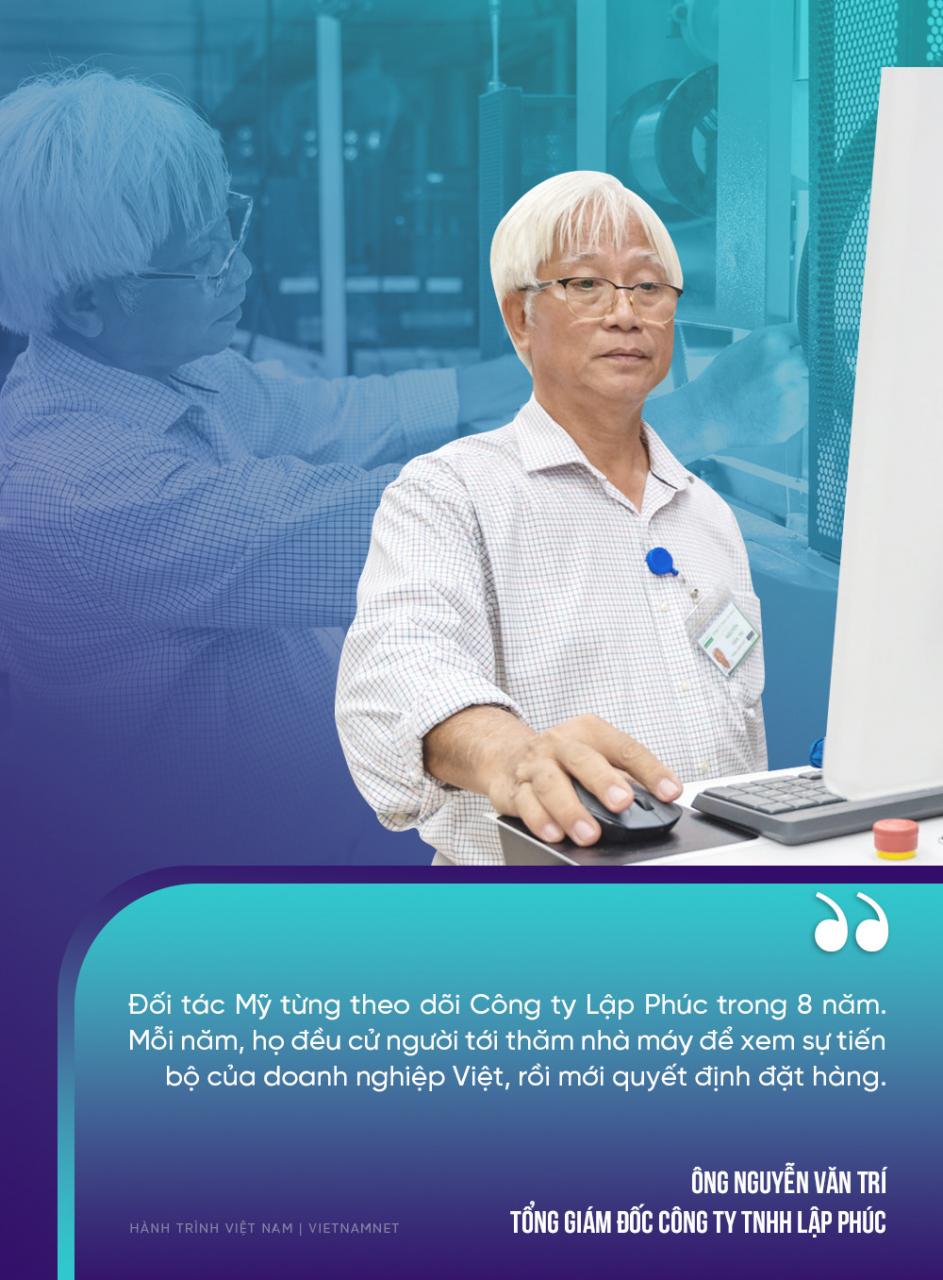

Talking with his mouth and working with his hands, Mr. Nguyen Van Tri, General Director of Lap Phuc Company Limited, quickly adjusts a system of precision mechanical equipment worth tens of billions of VND/machine at a factory in District 7 (HCMC). At the age of 64, he shows no signs of fatigue, his eyes showing great passion for the job. Every day, he still works at the factory, observing and instructing mechanics when needed.

More than 30 years ago, Mr. Tri was an employee of the Southern Agricultural Machinery Company (Vikino), which was one of the leading mechanical units in the Southern region at that time. During his time working here, he learned the meticulous work process of the Japanese. In addition, he also actively accumulated knowledge through self-study in books. Gradually, from a technician, he was appointed to become the factory manager of the enterprise.

In 1994, Vikino Company downsized its staff, he proactively asked to resign, making way for the younger generation and decided to start a business at the age of 35. Mr. Tri chose to be a role model, due to his long-standing knowledge related to mechanics.

However, experience is not enough, he said, high-tech machines are needed to apply in production, to improve competitiveness. High-tech design will be like the heart of the precision mechanical industry. That is why, right from the company's establishment, he went to Taiwan (China) to buy CNC milling machines from that country for use. This was one of the most modern milling machines in Vietnam at that time, helping mechanics understand digital technology, measuring, and cutting precisely in three-dimensional space.

To own the milling machine, he had to borrow a lot of money from family and friends. He agreed to sell his 80 m2 house on Hoa Hung Street (District 10) to save money to buy the machine. “I calculated that selling my house was only enough to buy 1/4 of the machine. However, if I had not invested a large amount of money, the company would not have been able to make progress like today,” he said.

To produce products that meet and join the global value chain of large corporations in Europe and the US, it is a journey of effort from the General Director as well as his colleagues at Lap Phuc Company.

One of the first major partners of the company was the Colgate Company. 13 years ago, the multinational company Colgate-Palmolive (USA) set a very high standard for toothbrush production. To understand better, hold a toothbrush in your hand and look closely. Few people know that the toothbrush is made up of two halves joined together. The boundary between the two halves is a line thinner than a hair, running from the handle of the toothbrush to the head of the toothbrush, it is almost non-existent.

The partner requires that the Colgate toothbrush head must be smooth, with a thin line on top that is not wavy, not sharp, and not causing injury to consumers when putting the toothbrush in their mouth to brush their teeth. This requirement is to protect the health and safety of consumers.

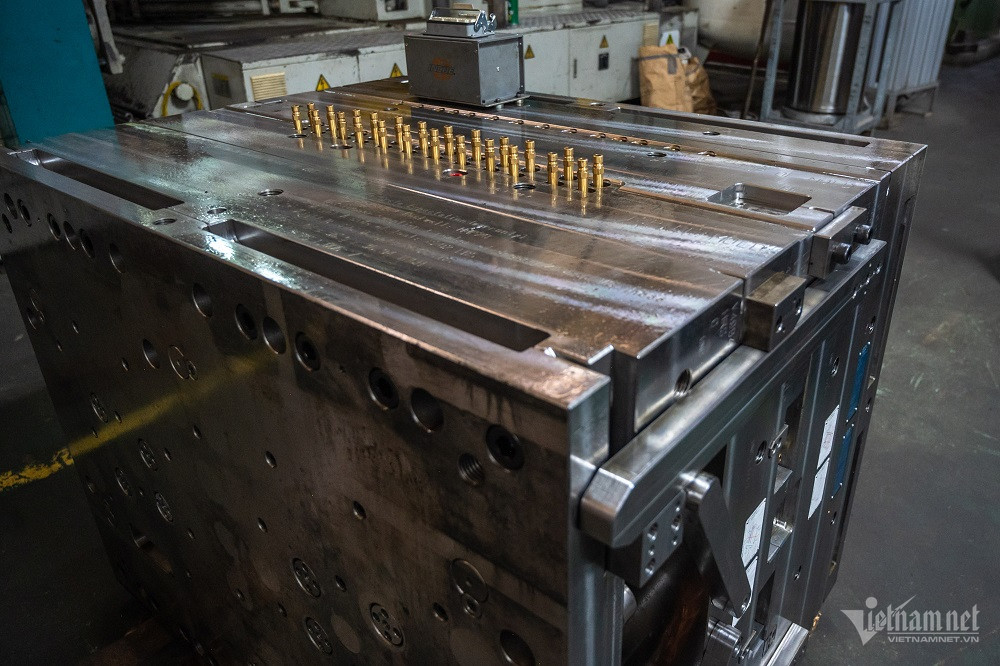

With the above difficult problem, Mr. Tri said, the company had to manufacture two halves of the toothbrush mold, so that when put together, there would be almost no unevenness, absolute asymptotic precision, and the border between the two toothbrush pieces would not appear clearly on the final product.

In addition, Colgate also asked Lap Phuc Company to make molds to press 24 toothbrushes at a time. A single precise mold is difficult, now the company has to make 24 molds to press the product precisely at the same time.

To solve the problem, each new toothbrush mold is made, the worker must look at the mold under a microscope hundreds of times to check for errors at the factory, before sending it to the American partner for acceptance. If not satisfied, the partner can return the product and request for corrections, which is normal.

After a whole year of hard work, Mr. Tri's company finally created a satisfactory mold product for the customer. Many mechanical units had participated in producing toothbrush molds for Colgate but gave up halfway. 13 years ago, Lap Phuc was the only enterprise in Vietnam to successfully carry out this project. From the above precise molds, Colgate-Palmolive Vietnam Company in My Phuoc III Industrial Park (Binh Duong) has produced about 250 million toothbrush products/year, for global consumption.

After the successful project for Colgate, American customers introduced each other to the identity of a precision mechanical processing unit in Vietnam. From here, Lap Phuc Company gradually participated in the large global value chain of Suzuki, Panasonic, Sanyo or Omron... 4 years ago, the company started making precision molds for famous car manufacturers such as Tesla, GM (General Motors).

“There are many details on cars, partners often give difficult parts to Vietnamese people to make such as shock absorber molds, electric car battery boxes, etc. The molds must be made according to the right technique, otherwise, when the product is pressed out, the car will crack after running for several hours. Not to mention, the details must be considered to be able to withstand exposure to rain and sun, there are highly precise molds with sizes larger than people,” the General Director shared.

Regarding the products that the company has manufactured, Mr. Tri said that each precise mold has its own level of difficulty, and the company likes to take on difficult details because of the high economic efficiency. In addition to the difficulty, the higher the difficulty, the more interesting it is for engineers in the mechanical profession and the more respect they receive from customers.

He cited that the American partner had been following Lap Phuc Company for 8 years. Every year, they sent people to visit the factory to see the progress of the Vietnamese enterprise, and then decided to place an order.

Specifically, on the stainless steel drum of the Whirlpool washing machine, there is a round plastic frame detail, which helps keep the machine balanced when rotating the water centrifuge drum. If the mold is not made properly, the washing machine will vibrate when drying. This is a detail with a difficult mold. This project of the Whirlpool Home Appliance Corporation (USA) has 5 mold samples. The intermediary partner is the A1 Group (a famous unit specializing in precision mechanics, headquartered in the US), ordering Lap Phuc Company to make 4 products, they make 1 product.

At first, the US side did not believe that the Vietnamese company could do the job. When Mr. Tri went to meet the partner, the leaders of the other company only greeted him politely, shook hands and then left. Five years later, when Lap Phuc Company produced 4 Whirlpool washing machine component molds that met the requirements, he returned to A1 Group to work, the leaders of the partner company showed a completely different attitude. They hugged Mr. Tri and called him "colleague", showing respect. Lap Phuc Company helped the intermediary partner win orders from a large global production chain.

“In the past 30 years, we have not been lucky in winning contracts,” Mr. Tri affirmed, adding that part of the success was due to the company having to reinvest large amounts of money in mechanical equipment.

Regarding the future direction of the enterprise, he said that the enterprise wants to be a processing unit of large global mechanical corporations. That is, Lap Phuc Company becomes a key mold factory, an international processing specialist, providing precision mechanical products.

Currently, contracts come to the unit through international mechanical corporations as intermediaries (mostly contracts come from the US). Mr. Tri commented that the precision mechanical engineering field in the US does not have a successor generation. 100% of American mold companies are immigrants from Germany, the owners are German-Americans. These companies have been established for 2-3 generations, skilled workers have reached retirement age. Up to now, young Americans do not want to continue their lineage and follow the heavy mechanical profession.

Therefore, American mechanical corporations will mainly receive work and then transfer it to processing companies like Lap Phuc to carry out production. In the future, American mechanical enterprises will be like international product warranty agents. With this cooperation method, even during the epidemic season, orders are still stable, and the 220 employees of Lap Phuc Company never lack work. Along with that, when cooperating through intermediaries, Vietnamese mechanical companies do not have to compete directly with domestic or international mechanical enterprises.

![[Photo] Prime Minister Pham Minh Chinh receives Swedish Minister of International Development Cooperation and Foreign Trade](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/12/ae50d0bb57584fd1bbe1cd77d9ad6d97)

![[Photo] Prime Minister Pham Minh Chinh works with the Standing Committee of Thai Binh Provincial Party Committee](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/12/f514ab990c544e05a446f77bba59c7d1)

![[Photo] Prime Minister Pham Minh Chinh starts construction of vital highway through Thai Binh and Nam Dinh](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/12/52d98584ccea4c8dbf7c7f7484433af5)

Comment (0)