In 2025, Khe Cham Coal Company aims to exploit more than 2 million tons of coal. This is one of the units with high underground coal mining output of TKV. To achieve this goal, the Company proactively takes advantage of favorable weather, arranges human resources and equipment reasonably, and maintains stable production. Tunnel digging and site preparation work is being carried out vigorously, ensuring progress and meeting production requirements.

By the end of July 2025, Khe Cham Coal had completed many important targets with raw coal output reaching 1.3 million tons and coal consumption reaching 1.31 million tons. Under conditions of increasingly deep mining, weak rock walls and difficult construction, the tunnel excavation volume was nearly 10,000m3. Notably, the average salary of workers reached 23.5 million VND/person/month, of which miners alone reached 23.15 million VND, ensuring a stable life and income for workers throughout the Company.

Not only making efforts in production, Khe Cham Coal also promotes the application of mechanization and automation in coal mining and tunneling. The automatic monitoring and control system in phase I has been completed, promoting efficiency in serving production. Technical management has been enhanced, from production and mining planning to synchronous construction of transportation routes, electricity, water and ventilation systems to improve working conditions in the mine.

Comrade Le Dinh Duong, Director of Khe Cham Coal Company, said: In the third quarter, the Company aims to produce and consume 450,000 tons of coal, and dig 4,690m of new tunnels. To achieve this goal, the Company has built a group of drastic management solutions, closely following production practices. In particular, focusing on continuing to implement measures to prevent cutting, lowering the foundation, and renovating the tunnel system to improve working conditions and increase transportation efficiency in the tunnel; speeding up the construction of tunnel lines according to the plan to go deep to -300 to -460; maintaining molding work in key areas, regularly checking terrain, ground and preventing storms.

The unit reviews and develops monthly and quarterly technical and technological plans to ensure adequate production space and improve productivity; focuses on improving working conditions for workers by installing hoists and cable cars to serve the needs of travel and material transportation in the tunnels. At the same time, closely follows the scene and prepares a plan to transfer the tunnel to ensure progress in the third quarter and the whole year.

Regarding cost management and administration, the Company focuses on tightening production discipline, promoting the responsibility of leaders; promoting mechanization, automation and digital transformation in production stages. Management solutions are implemented drastically, focusing on assigning contracts, controlling internal costs close to reality, and strictly managing wages linked to productivity and working days. The Company also implements transparent cost settlement, clearly assigning material responsibilities to each unit to promote the spirit of saving, improve efficiency and income of workers.

The recovery and reuse of old equipment and materials are enhanced to reduce new investment costs. The energy saving program is implemented synchronously, associated with the application of information technology in management, especially the application of electronic signatures, contributing to streamlining processes and improving the efficiency of production and business operations.

The care for workers continues to be maintained with many practical policies. The company arranges shuttle buses to pick up workers from their residence to the mining site, supports accommodation conditions, provides periodic health check-ups, invests in air conditioning, wifi, elevators in the dormitory area and has special policies for people in difficult circumstances. Cultural and sports activities, competitions on occupational safety and hygiene are also held regularly, creating a competitive atmosphere throughout the company.

Source: https://baoquangninh.vn/khe-cham-tang-toc-thuc-hien-muc-tieu-quy-iii-3370235.html

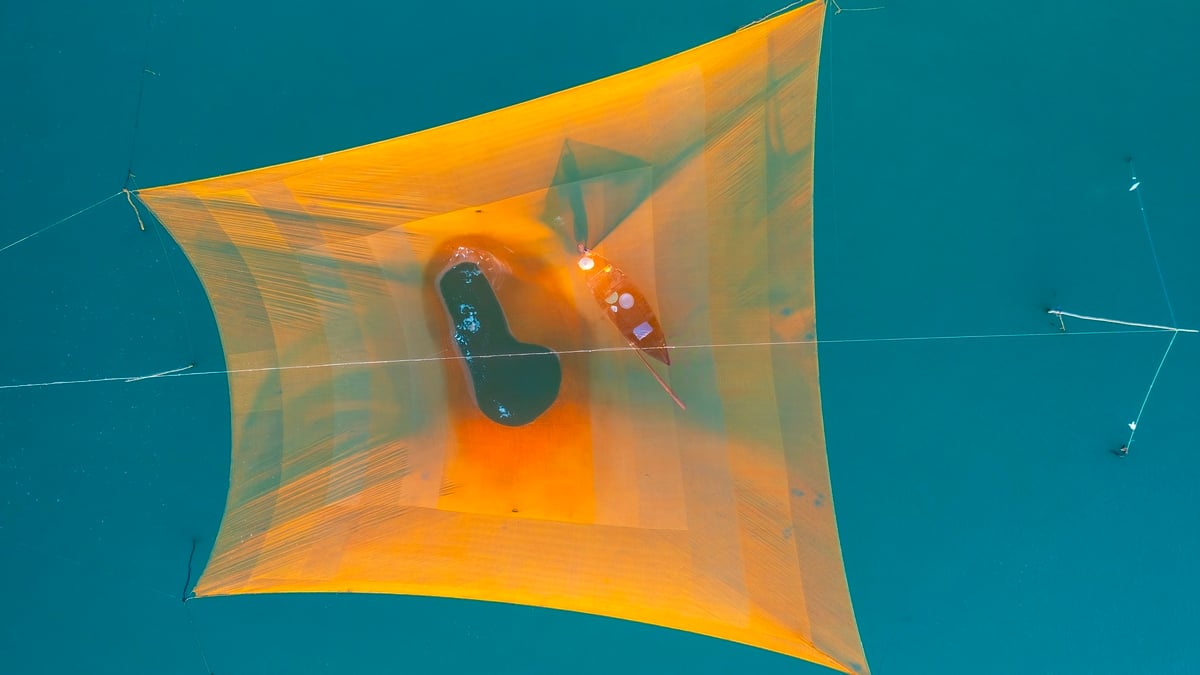

![[Photo] Discover the "wonder" under the sea of Gia Lai](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/8/6/befd4a58bb1245419e86ebe353525f97)

Comment (0)