A group of students in Da Nang used hydraulic pressing techniques with appropriate heating levels to successfully create a dish-forming machine from areca spathe, with a capacity of 60 products per hour.

Da Nang: Students create dish press machine from areca spathe to replace plastic products

Tuesday, November 26, 2024 14:33 PM (GMT+7)

A group of students in Da Nang used hydraulic pressing techniques with appropriate heating levels to successfully create a dish-forming machine from areca spathe, with a capacity of 60 products per hour.

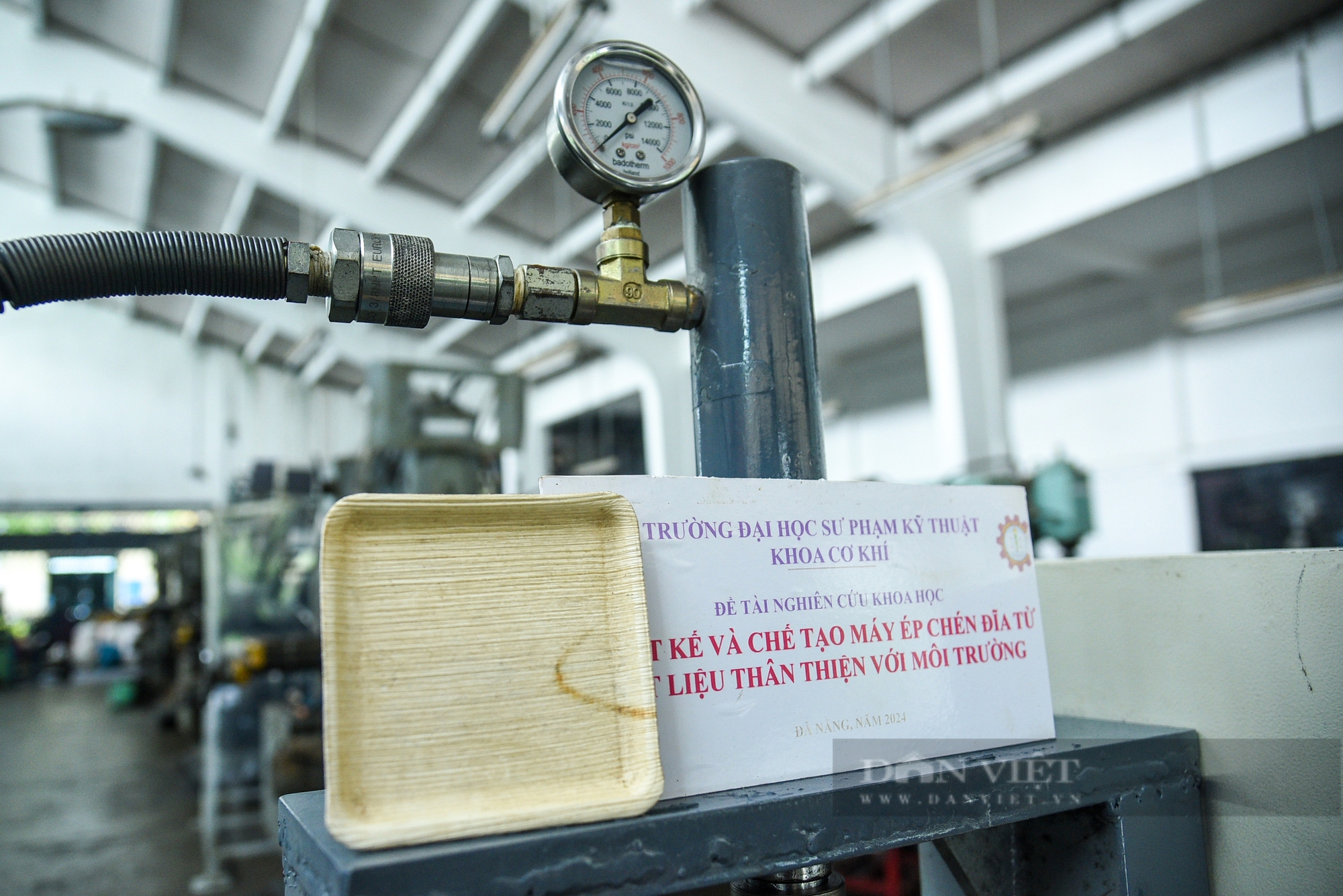

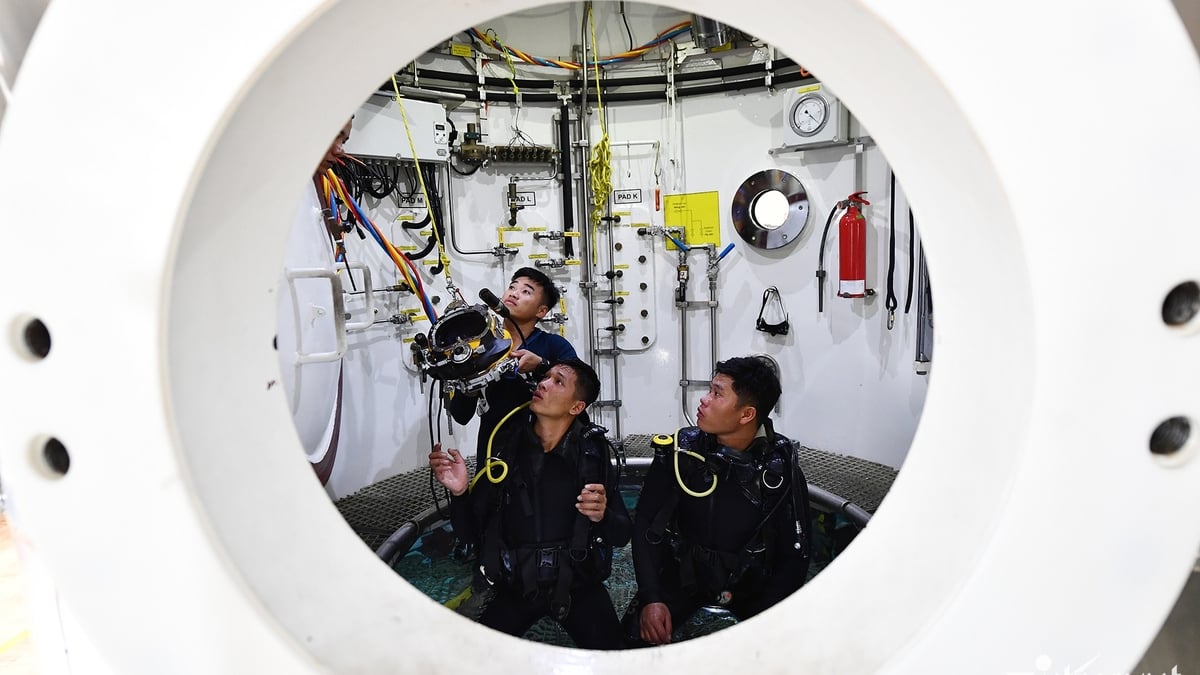

Using hydraulic pressing technique with appropriate heating level, a group of students from Da Nang successfully manufactured a dish-forming machine from areca spathe, with a capacity of 60 products per hour. This is the product of a group of students including Le Van Tuan, Dang Huu Tai, Mai Xuan Son, Phan Tan Sang, Ho Van Ly (Faculty of Mechanical Engineering, University of Technical Education, Da Nang University).

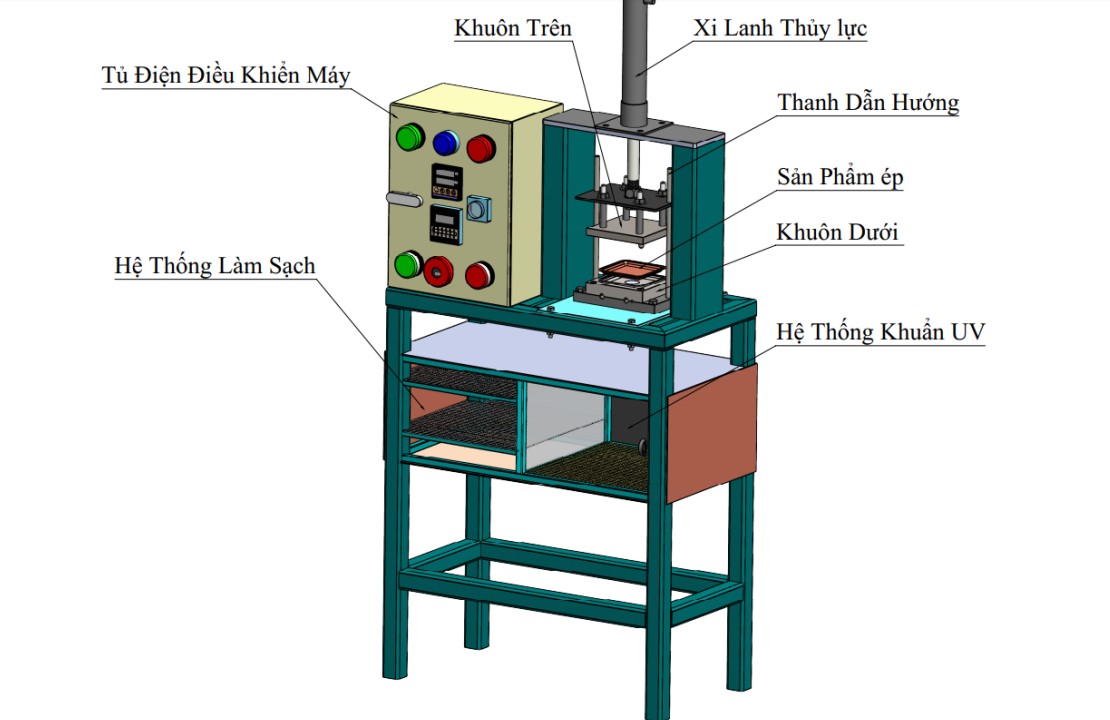

The machine is rectangular in shape made of steel pipes joined together, 1.2m high, nearly 70cm wide, and weighs about 150kg.

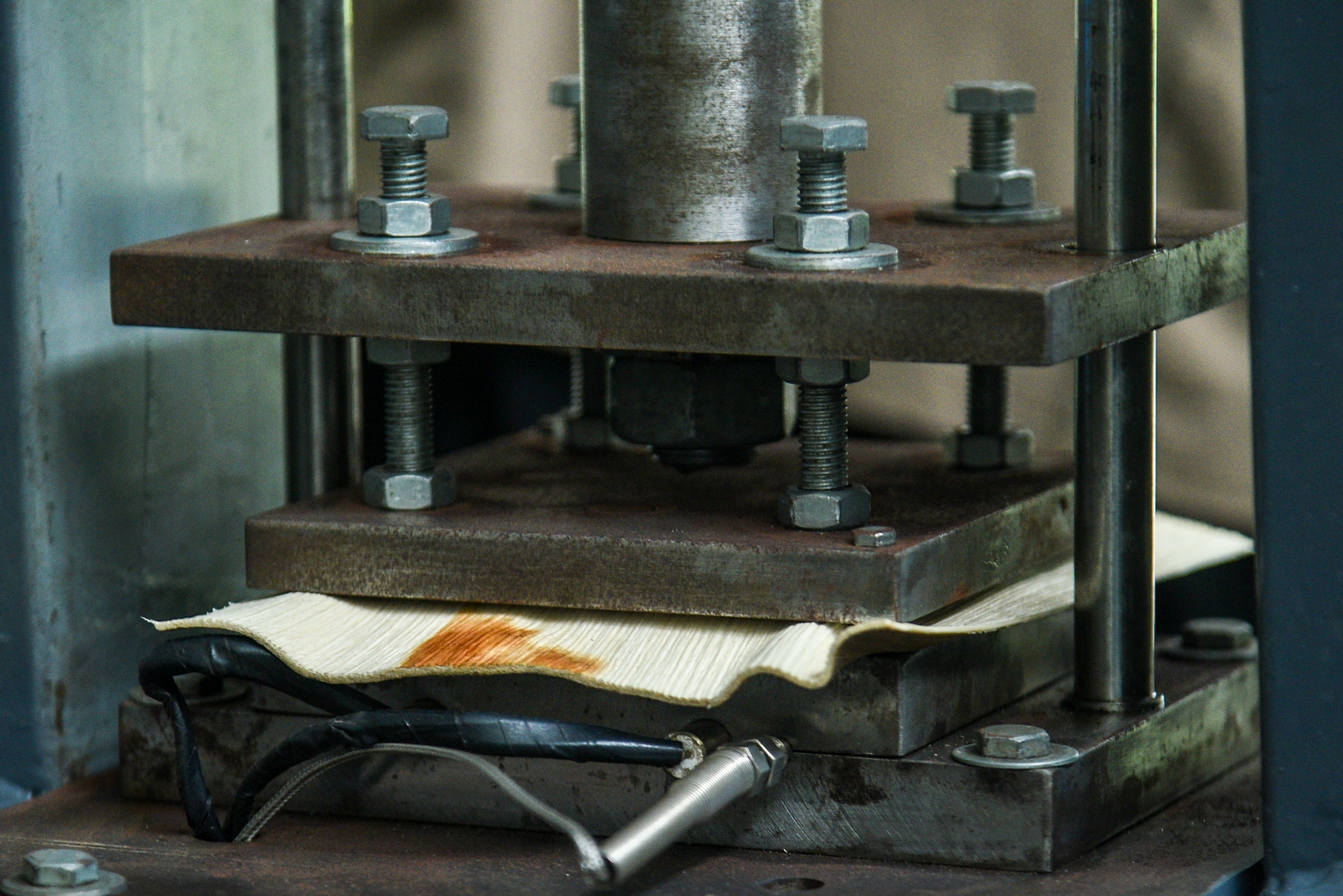

The machine has a hydraulic cylinder piston press, a dish forming mold, controls and a cleaning system.

When pressing the button on the control panel, the heating system starts to increase the temperature in the mold to about 120 - 180 degrees Celsius in 60 - 90 seconds.

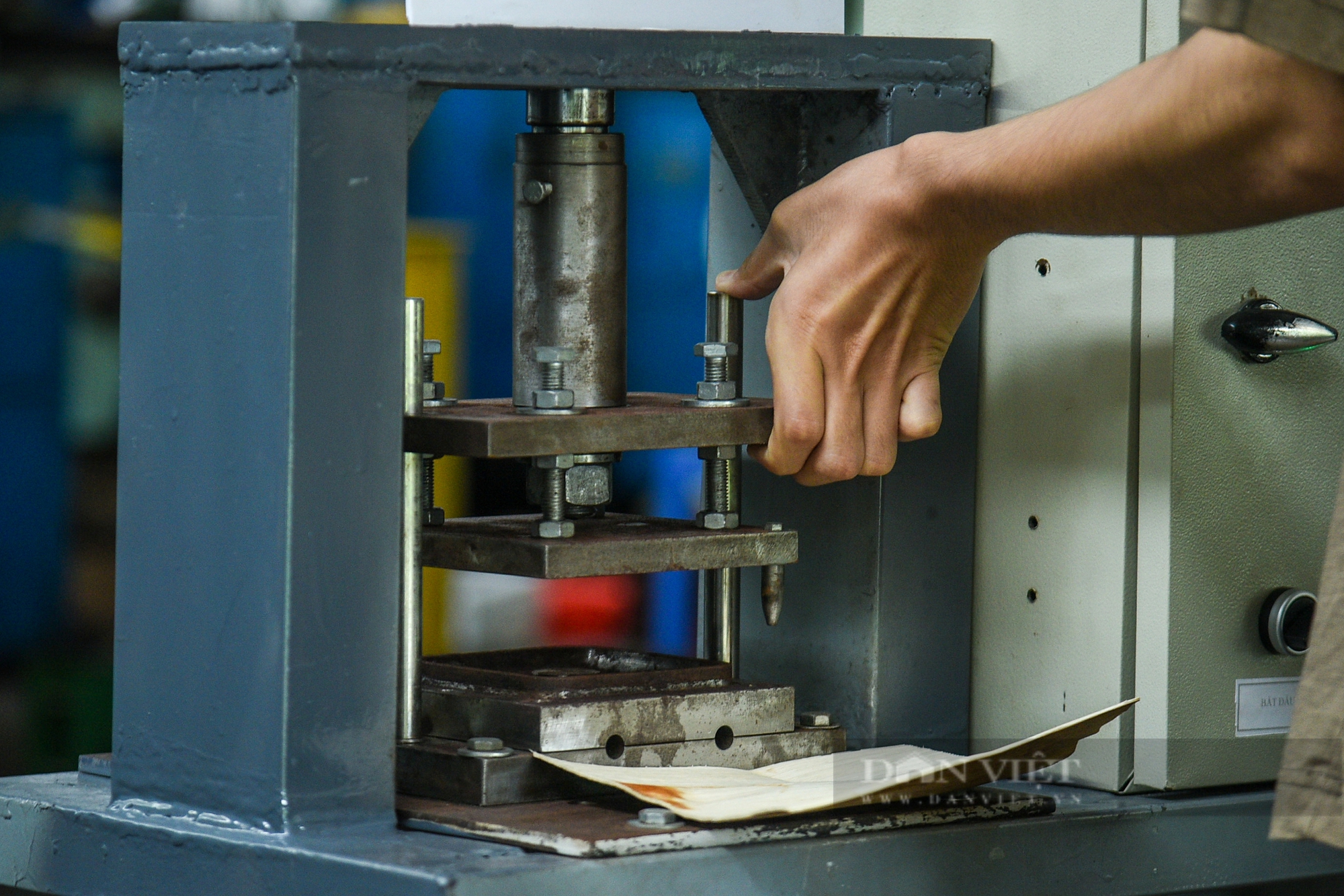

When feeding the raw material into the mold, the user presses the button on the control panel to supply power to the hydraulic machine. The piston performs the stroke to create pressing force to shape the product and then retracts back into the cylinder, ending the process.

Before being pressed, the areca spathe is cleaned with high pressure compressed air to blow out dirt, increasing the cleanliness of the material surface. After successfully shaping the dishes, they are cleaned with UV light in the machine's tray. During operation, in case of an emergency, the user will press the button to cut off the power and the parts will stop working.

"For each different material, the temperature will be adjusted appropriately to create the best quality product. With areca spathe and bamboo shoots, pressing time is one minute to produce one product, meaning the machine can create 60 products in one hour," shared group member Ho Van Ly.

The selected materials are areca spathe, bamboo shoots, coconut fiber shells, and leaves that are abundant in nature, with high cellulose content, so when pressed into shape, they have high durability and usability.

Phan Tan Sang (a member of the research team) said that during the manufacturing process, the team encountered many difficulties. Especially in researching the force generation system, because the actual stamping force is divided into many levels of force to be able to press and block the blank, deform the material and overcome the friction between the material and the upper and lower molds.

"After a period of testing, the team chose a hydraulic control system to optimize the force to create the most perfect product shape. Specifically, when putting the areca spathe into the mold, the user presses the air cleaning button on the control panel to power the control circuit. Air from the pressure tank will pass through the 5/2 valve to the nozzle, creating a high-pressure air flow to push dirt on the surface. A significant advantage is that the machine is optimally designed with a compact size, aesthetics, high safety, and ease of use...", Phan Tan Sang shared more.

Funding is also a headache for students. It is known that to manufacture the dish press, the student group received 4 million VND from the school. Then, group members and Dr. Bui He Thong (lecturer of the Faculty of Mechanical Engineering) contributed another 2 million VND to start researching and manufacturing.

"If we receive financial support for the design and improvement of the machine in the future, the research team can focus on more in-depth research to improve machine productivity, evaluate factors affecting the product to have a good product in terms of quality as well as price. The research team really hopes that the product can be developed and replicated or can be applied in production," said Dr. Bui He Sy.

3D design of the machine. Photo: NVCC

Writing

Source: https://danviet.vn/da-nang-sinh-vien-che-tao-may-ep-chen-dia-tu-mo-cau-thay-the-do-nhua-20241126135108069.htm

Comment (0)