Improve construction quality and save costs.

Currently, the building materials industry has met the needs of construction and infrastructure development nationwide. Many products have entered the export market, such as clinker, energy-saving glass, tiles, paving stones, sanitary ware, etc. The development of building materials has gradually focused more on sustainable development and environmental protection.

To date, along with the development of science and technology, building materials have been increasingly researched and many types have been produced with new, superior characteristics, being environmentally friendly and highly durable, such as: self-healing concrete, green concrete, ultra-high performance concrete; artificial paving stones, etc.

For example, energy-saving glass can help save 52% on heating costs, reduce air conditioning power consumption by 53%, and block up to 99% of harmful UV rays. PVD coating technology for faucets offers many superior features such as water saving, environmental protection, safety for users' health, exceptional durability, easy cleaning, and a wide variety of colors.

Furthermore, building materials that utilize nanotechnology in their production offer high economic efficiency, such as those used in the manufacture of paints or additives for cement and concrete. 3D printing technology helps minimize material waste and save labor costs. Simultaneously, 3D printing is used to create detailed architectural models, allowing contractors and architects to easily visualize and adjust designs before construction begins.

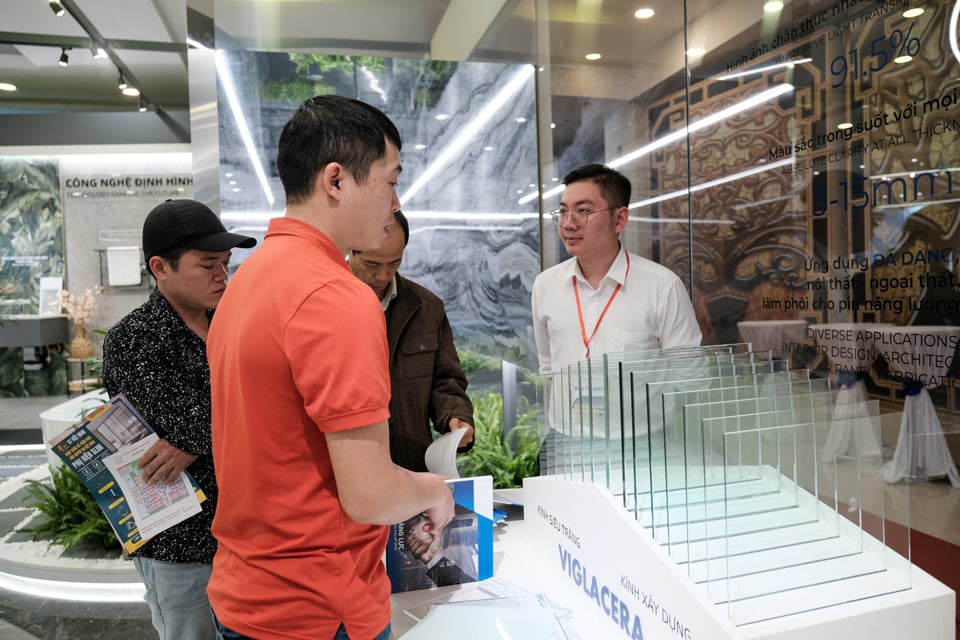

Interior partition materials (walls, dividers, etc.) are also trending away from brickwork and towards hollow concrete panels, compact panels, fiber cement flat panels, glass, gypsum boards, and sound-absorbing mineral fiber panels. These materials offer numerous advantages such as shorter construction time, greater flexibility in use, improved aesthetics, space savings, and better sound and heat insulation than traditional building materials.

According to Engineer Le Cao Chien, Deputy Director of the Center for Equipment, Environment and Occupational Safety at the Institute of Building Materials, there are six global trends in the use of green materials: energy efficiency in buildings; recycling and reuse of building materials; use of materials from renewable resources; materials that are friendly to human health; biotechnology and biodegradable materials; and the use of smart technologies and materials.

With the development of biotechnology and smart materials, the future of green construction will continue to flourish. Furthermore, industry experts recognize that, in the current context, green building materials are increasingly replacing traditional building materials and are poised for significant growth.

In terms of legal framework, Vietnam has issued a system of documents, such as the Law on Environmental Protection with regulations on environmentally friendly products, green procurement and green bonds; Decision No. 889/2020/QD-TTg, approving the National Action Program on Sustainable Production and Consumption for the period 2021-2030; Decision 1658/QD-TTg on the National Strategy on Green Growth for the period 2011-2020 and vision to 2050; Decision No. 1266/QD-TTg on the Strategy for the Development of Construction Materials in Vietnam for the period 2021-2030, orientation to 2050…

Furthermore, building materials were selected as one of four proposed sectors that will receive preferential green loans (agriculture, forestry and fisheries; industry; renewable energy and building materials) to meet the production and sustainable development requirements of the industry, especially in the context of Vietnam's relatively large need for infrastructure and civil works construction.

Focus on investing in training and human resource development.

Vietnam has many opportunities to develop the green building materials industry thanks to its abundant natural resources, potential for recycling various materials, and increasing demand from global trends. However, to effectively capitalize on these opportunities, strong investment in infrastructure, supportive policies, and increased consumer awareness of the benefits of green building materials are needed.

However, Vietnam still lacks a set of criteria for green labels/eco-labels/green building materials, leading to the existence of many counterfeit, imitation, and substandard products, which significantly affect consumers.

Although there are approximately 465 green labels in 199 countries worldwide, covering 25 industries, the green labeling programs are all voluntary, with a certification body affixing the label to products to indicate their environmental friendliness.

Furthermore, there is no established system of standards for the production and use of green building materials in construction projects; preferential policies and mechanisms for the production, business, and use of building materials labeled with the Vietnam Green Label/green materials and of high quality are limited; and the human resources, from the production of green materials to the consulting, project planning, design, construction, and acceptance of projects using green materials, do not meet the needs.

According to Tran Van Hoa, Director of Hoa Thanh Building Co., Ltd., typically, the cost of a civil construction project is 30% for the rough construction phase and 30-40% for the interior finishing phase. Therefore, building materials account for 70-80% of the total construction cost. Using high-quality building materials can save contractors tens of billions of dong on repairs and maintenance thanks to the use of solar power, natural ventilation systems, and energy optimization solutions.

However, many businesses and investors have not yet fully recognized the fundamental long-term benefits of green materials, such as reduced energy consumption, improved indoor air quality, and minimized environmental impact. Finding energy-efficient building materials is difficult, and there is a shortage of skilled personnel. Therefore, to boost the number and quality of green buildings in Vietnam, finding solutions to address these concerns is crucial.

"Therefore, in addition to improving product quality, businesses in the building materials industry need to focus on providing an efficient supply chain to meet the material needs of construction projects, contributing to accelerating construction progress and minimizing the risk of unexpected costs."

"In addition, the workforce must be well-trained and possess high professional skills to perform the job with the best quality. This requires investment in training and human resource development," Mr. Tran Van Hoa shared.

To date, Vietnam has 559 green-certified buildings with 13.6 million m2 of floor area. Of these, EDGE (Excellence in Design for Greater Efficiencies) certification accounts for the largest proportion (41.80%) of the total number of green buildings. This is followed by LEED ( Leadership in Energy and Environmental Design) certification and Green Mark certification.

Source: https://kinhtedothi.vn/co-hoi-rong-mo-cho-vat-lieu-xanh.html

![[Image] The tenacious fighting spirit of Vietnamese women's football](/_next/image?url=https%3A%2F%2Fvphoto.vietnam.vn%2Fthumb%2F1200x675%2Fvietnam%2Fresource%2FIMAGE%2F2025%2F12%2F17%2F1765990260956_ndo_br_4224760955870434771-copy-jpg.webp&w=3840&q=75)

![[Live] 2025 Community Action Awards Gala](/_next/image?url=https%3A%2F%2Fvphoto.vietnam.vn%2Fthumb%2F1200x675%2Fvietnam%2Fresource%2FIMAGE%2F2025%2F12%2F16%2F1765899631650_ndo_tr_z7334013144784-9f9fe10a6d63584c85aff40f2957c250-jpg.webp&w=3840&q=75)

![[Photo] Prime Minister Pham Minh Chinh receives the Governor of Tochigi Province (Japan)](/_next/image?url=https%3A%2F%2Fvphoto.vietnam.vn%2Fthumb%2F1200x675%2Fvietnam%2Fresource%2FIMAGE%2F2025%2F12%2F16%2F1765892133176_dsc-8082-6425-jpg.webp&w=3840&q=75)

Comment (0)