A group of students from the University of Technical Education (University of Danang ) have just created a machine that presses leaves and natural materials into cups, plates, glasses...

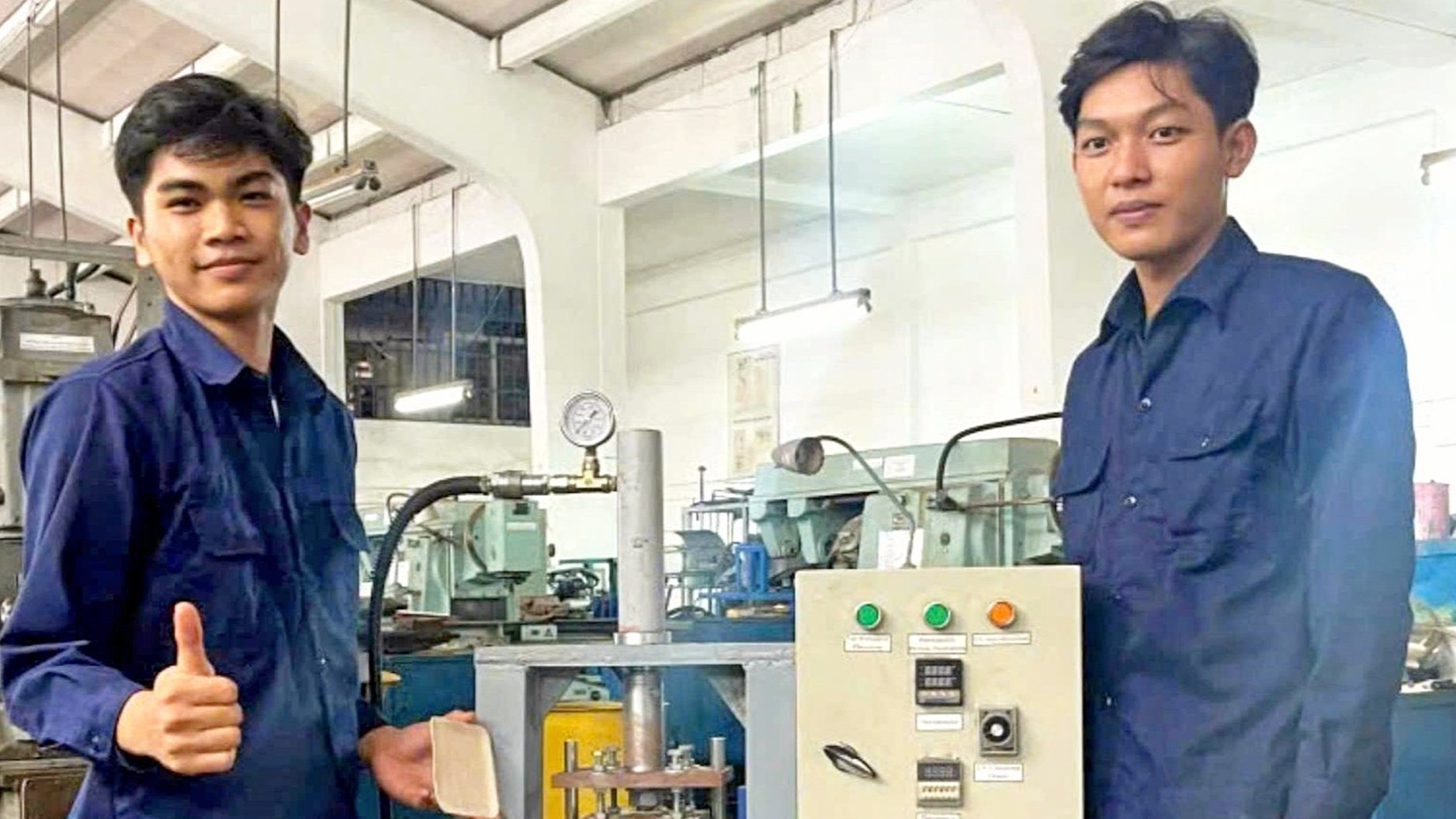

The press that creates dishes from natural materials by Da Nang students - Photo: LVT

The initial non-optimal mold design also caused many obstacles, but we constantly improved and optimized the production process to be able to create a complete product.

Student LE VAN TUAN

The group includes students Le Van Tuan, Dang Huu Tai, Mai Xuan Son, Phan Tan Sang and Ho Van Ly. They have researched and designed a leaf press machine, using banana leaves, areca spathes, bamboo shoots, lotus leaves... as materials and created many products to replace plastic products and foam boxes.

Team leader Le Van Tuan said that the idea was formed in early 2024 and together they researched for about half a year to gradually complete the press model.

After being cleaned and disinfected, the natural materials will be put into the mold. The pressing process takes about 30 seconds or less depending on the material to form products such as bowls, plates, and glasses. The products will then go through a UV sterilization system to remove bacteria and mold, ensuring safety for users.

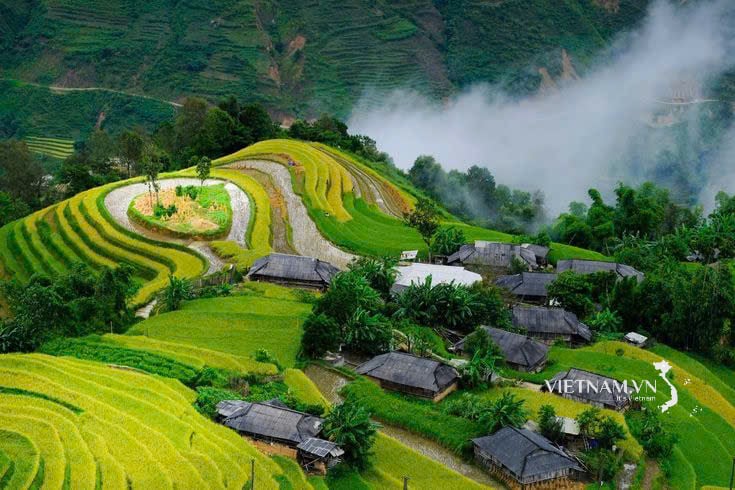

Areca spathe, bamboo shoots, banana leaves, lotus leaves... are agricultural waste products that are often discarded. However, through research, the group has taken advantage of them and created useful products that are easily biodegradable in the environment and do not cause pollution like plastic.

Student Le Van Tuan said one of the biggest challenges is that the school lacks processing equipment. Therefore, students have to borrow machines from outside processing factories.

The initial results give you the confidence to research other materials to see if they can be used. At the same time, we are also testing products that can withstand higher temperatures so that hot food bowls and plates will not affect the quality.

Although not yet fully commercialized, there have been customers contacting the group to place orders, especially restaurants and souvenir shops in Da Nang. This makes them more confident because the source of agricultural waste materials in the Central region is abundant, and products can be produced at reasonable and competitive prices.

Instructor Bui He Sy said that there are similar dish presses on the market, but he is confident because his student's product integrates UV sterilization technology along with the conversion of technology from hydropneumatic to improved hydraulic.

Mr. Thong said that although the whole process has not been fully optimized or automated, the product created with only a few million VND is very encouraging.

"The machine not only brings practical value but also helps students develop creative thinking and realize the knowledge they have learned in the classroom," emphasized Mr. Thong.

Unique dishes made from leaves

Unique dishes made from leavesSource: https://tuoitre.vn/may-ep-la-cay-mo-cau-thanh-chen-dia-khu-khuan-bang-tia-uv-20250304235853042.htm

![[Maritime News] Two Evergreen ships in a row: More than 50 containers fell into the sea](https://vphoto.vietnam.vn/thumb/402x226/vietnam/resource/IMAGE/2025/8/4/7c4aab5ced9d4b0e893092ffc2be8327)

Comment (0)