At the age of 60, Mr. Tran Hoai Nam is still covered in mud, rolling up his sleeves in the yard, but in the eyes of the villagers, he is the "village engineer". Originally a military soldier, after leaving the army, Mr. Nam worked as an auto repairman in Vinh city, then returned to his hometown to do agricultural production. But he always had one thing in mind, that was the time of famine, in the lean season, the rice in the field was only ripe with a few ears, his parents harvested each branch, threshed by hand, and roasted each grain in a pan to get rice to cook to fight hunger.

.jpg)

“Back then, roasting rice in a cast iron pan and pounding it with a pestle was very hard work. But strangely, the rice cooked from that roasted rice was more delicious and fragrant than rice dried in the sun,” Mr. Nam recalled, his eyes looking far away. Later, having the opportunity to travel to many places, from the Mekong Delta to Thailand, he realized a common point: The quality of delicious rice depends largely on the drying technology after harvest.

Thinking is doing, in 2024, he started researching and manufacturing a rice dryer - something that few people believed a farmer could do. With no capital, no standard design, and no modern technological equipment, he studied each principle, watched videos online, took pictures of factory dryer models, took meticulous notes on each page of old notebooks and experimented.

"The difficulty for farmers in inventing is not thinking but capital and design. The rest, just need to grasp the principle to do it," Mr. Nam shared.

.jpg)

For a whole year, his yard was filled with the sound of cutting machines, the smell of welding smoke, and piles of scrap metal. He bent, welded, assembled, tested, and then disassembled and adjusted. By the end of May 2025, his first rice dryer was officially operating smoothly. No one expected that his machine would be "tested by fire" at the same time Nghe An suffered from prolonged unseasonal rains, causing large areas of rice to not be able to dry, become moldy, and even sprout.

When people were struggling to save their rice, Mr. Nam’s dryer became a “lifesaver”. “When we heard that Mr. Nam had successfully invented a dryer, everyone was happy. Luckily, thanks to his machine, my 5 tons of rice were saved from sprouting”, said Ms. Nguyen Thi Huong in Hung Son hamlet, Kim Lien commune.

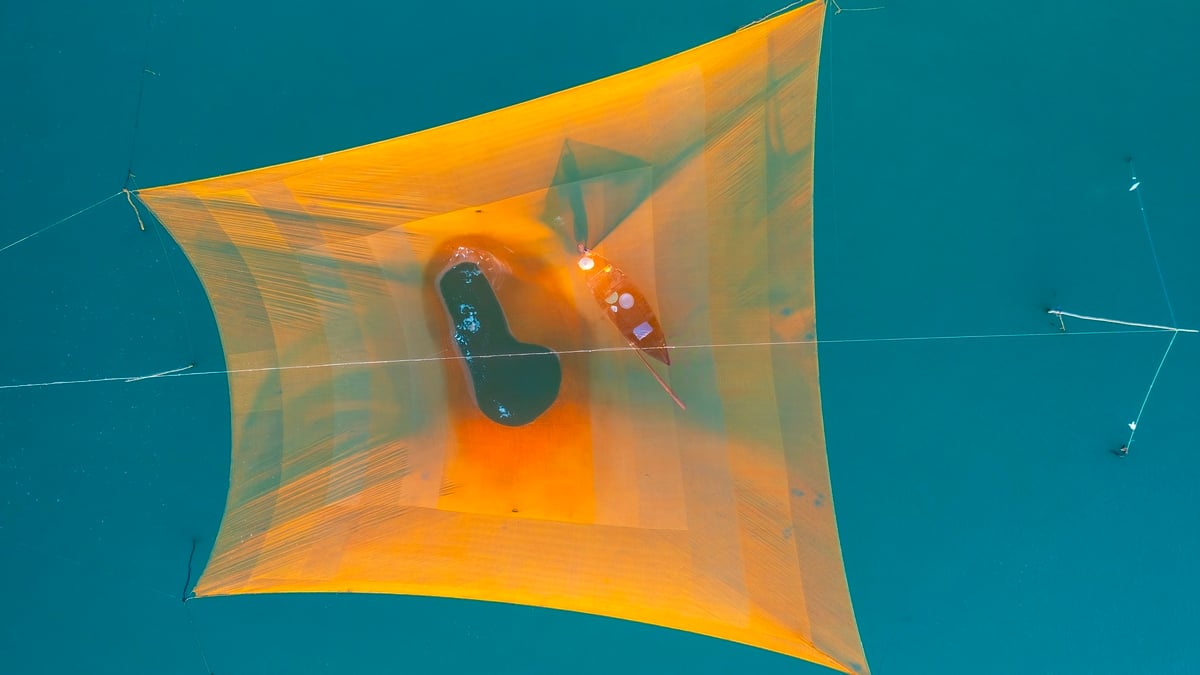

Mr. Nam's rice dryer has a capacity of 1.5 tons per batch, drying time of 4 hours, using charcoal fuel, but is designed to absorb heat in a closed system, does not create smoke, does not pollute the environment. The dryer has a fan system that blows hot air, goes through the inverter, and absorbs moisture to dry the rice grains evenly. Each batch only consumes about 15 kg of firewood and a few kWh, the cost is much lower than other dryers on the market.

Mr. Nguyen Duc Thuan - a trader specializing in purchasing and exporting rice shared: "I brought the first batch of rice to try drying with Mr. Nam's machine. The result was unexpected: The rice reached the ideal moisture level, the rice was fragrant, sticky, firm, beautiful in appearance and more profitable than drying in the sun. If we added an automatic rice pouring and unloading mechanism, it would be great."

.jpg)

While the machine was being tested, the whole village came to watch, everyone was amazed. Some brought bags of rice waiting to be dried, others took photos and videos to share. Mr. Nam operated the machine, adjusted the temperature, and watched the clock, not letting it get too hot or too low. Although the machine was overloaded and there were no assistants, Mr. Nam still did not refuse any of the villagers. Because he understood that each grain of rice was the result of a whole season's work, it would be heartbreaking to let the rice steam and germinate because of the rain and then throw it away.

Not only stopping at technical solutions, the dryer also changes the awareness of farming and post-harvest preservation for farmers. “The deliciousness of rice is thanks to the bran layer. When dried properly, the rice bran turns into essential oils, permeates inside, making the rice more sticky and fragrant. Drying also helps kill germs, prevent termites, and increase preservation time,” Mr. Nam analyzed.

.jpg)

Mr. Tran Van Thien - Chairman of the Farmers' Association of Kim Lien commune affirmed: "Mr. Nam's invention of the dryer is a big step forward for farmers in the rice fields. During the rainy season, without a dryer, hundreds of tons of rice can be damaged. We are preparing a dossier to request recognition of him as a 'Scientist of farmers'".

As for Mr. Nam, after a whole year of tinkering with the invention, he only has a simple wish: “The machine is currently being tested and gradually perfected. I am willing to share the entire design and operating process of the rice dryer. I just hope that each hamlet and each cooperative will have a dryer like this, so that people will no longer have to worry about the rice grains changing color in the yard during the rainy season, and our hometown rice can reach further.”

Amidst the erratic weather, amidst the fields still struggling with the issue of “good harvest, low price – good price, bad harvest”, Mr. Nam’s invention not only dries rice but also proves that farmers can completely master technology, and create value from their own fields.

Source: https://baonghean.vn/nong-dan-nghe-an-sang-che-may-say-lua-tu-ky-uc-doi-ngheo-10298385.html

![[Photo] Nghe An: Provincial Road 543D seriously eroded due to floods](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/8/5/5759d3837c26428799f6d929fa274493)

![[Photo] Discover the "wonder" under the sea of Gia Lai](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/8/6/befd4a58bb1245419e86ebe353525f97)

Comment (0)