Imported frozen durian is strictly monitored and inspected.

The signing of the Protocol on inspection, quarantine and food safety for frozen durian exported from Vietnam to China by the Ministry of Agriculture and Rural Development and the General Administration of Customs of China (GACC) has marked an important turning point for the durian industry.

With the high demand from this market, Vietnam can earn an additional 400 - 500 million USD from exporting frozen durian in 2024. Not to mention, the new product will help diversify processing, reduce seasonal pressure, harvest output, and create greater added value for the durian industry.

However, the signing of the Protocol does not mean that frozen durian can be shipped to the border gate immediately. Like fresh durian, frozen durian will be subject to strict inspection and supervision according to China's Food Safety Law.

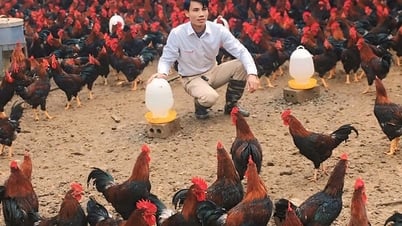

Peeling durian segments for freezing at a factory in Xuyen Moc district ( Ba Ria - Vung Tau province). Photo: PTM

According to the Plant Protection Department (Ministry of Agriculture and Rural Development), in the above Protocol, frozen durian (Durio zibethinus) includes whole durian fruit (with shell), pureed durian (without shell) and durian pulp (without shell), originating from fresh, ripe durian grown in Vietnam.

Frozen durian exported from Vietnam to China must be hand-selected to remove rotten and damaged fruits and ensure that they do not contain foreign metal impurities. Raw materials of frozen durian exported from Vietnam to China must originate from durian gardens registered with Vietnam.

The Vietnamese side will inspect the facilities producing, processing, and preserving frozen durian exported from Vietnam to China and introduce qualified enterprises to the Chinese side. Qualified enterprises must be registered with the Chinese side. Only after registration can enterprises export products to China.

Packaging materials for frozen durian exported from Vietnam to China must be clean, hygienic, unused, and comply with food safety and hygiene and plant quarantine requirements.

During the storage and transportation of frozen durian, the requirements of the International Food Standard - "Code of Practice for the Processing and Handling of Quick Frozen Foods" (CAC/RCP 8-1976) must be met.

Thus, frozen durian packaging facilities must meet requirements on food hygiene and safety, packaging processes, traceability and food safety control processes (HACCP). Along with that, there are some requirements on freezing capacity and cold storage.

Talking to Dan Viet, Ms. Phan Thi Men - General Director of SUTECH Science and Technology Consulting Company Limited said that the standards for frozen durian are much stricter than those for fresh durian, requiring manufacturers to comply with HACCP standards or equivalent such as ISO 22000:2018, BRC, FSCC 22000...

Frozen durian processing facilities must ensure that they prevent and avoid the risks of microorganisms, yeasts, and molds in the raw materials during harvest. The transportation process must be absolutely safe, without causing waterlogging or rotting of the product.

In particular, the dangers of pesticide residues, heavy metal residues... remaining in the cultivation process must be controlled and prevented.

The process of separating segments, separating seeds, and pureeing and freezing also requires high management and prevention of biological, chemical and physical hazards so that the product is not contaminated with E.Coli, Salmonella bacteria...

Regarding the factory, according to Ms. Men, the principle of factory layout must ensure one-way traffic, whereby the input of raw materials and the output of finished products are not on the same path to ensure no cross-contamination.

"For fresh durian packaging facilities, China is interested in quarantine measures for 6 pests on fresh fruit according to the Protocol. Packaging facilities must use physical measures to treat aphids such as spraying, washing, and manual treatment. As for frozen durian packaging facilities, it is necessary to ensure a closed, standardized process from the personnel involved in the process to the product processing and finished products," said Ms. Men.

Specifically, before participating in the production process, workers must change into protective gear (masks, helmets, gloves, disinfected clothes, etc.) to avoid dust and hair falling on the product.

During the production process, workers must comply with strict regulations on food safety conditions, identify hazards and prevent potential hazards at each stage of the production process; have logs and books to record the history of shipments. Conditions to ensure cold storage must comply with regulations (-45) degrees, deep freezing to maintain the value of processed products.

Hope to have specific instructions on exporting frozen durian soon.

In order to develop durian exports to the Chinese market sustainably, including frozen durian, Mr. Ngo Xuan Nam, Deputy Director of the Vietnam SPS Office (National Information and Enquiry Point for Food Safety and Animal and Plant Quarantine) said that producers need to fully meet the requirements of food safety, plant quarantine and traceability. In particular, pay special attention to 3 stages.

The first is the care of durian from flowering to harvest. This is the time to strictly comply with the Protocol on quarantine of fresh durian products signed with China, such as requirements on records, books, lists of pesticides, and ways to control 6 harmful organisms.

In addition, because China and Vietnam are both WTO members and participate in the RCEP Agreement (Regional Comprehensive Economic Partnership Agreement between 10 ASEAN countries and 5 partners: China, Korea, Japan, Australia and New Zealand), manufacturers also need to comply with related contents.

The second stage, according to Mr. Nam, is from the time of harvest to the time of transport to the packaging facility. In particular, Mr. Nam especially emphasizes the harvesting of durian at the right age (usually around 7.5 years old). This is a very important criterion to ensure the quality of durian segments.

In this step, packaging facilities need to strictly control the classification of durian according to the requirements of partners. For fresh durian, the surface of the fruit must be cleaned with clean water, free of soil, bark or other agents. In particular, avoid physical impact on the durian shell and thorns.

The final stage is from the packaging facility to the border gate. Since Vietnam's main durian growing areas are located in the Central Highlands and the Southwest, about half a week's transportation from China, the temperature at which durian is stored after preliminary processing will determine the freshness and deliciousness when it reaches the neighboring country.

According to SPS Office experts, durian needs to be kept cold at a temperature of 12-15 degrees Celsius before transporting to prevent it from rotting or spoiling.

From the perspective of an export consultant, Ms. Phan Thi Men added: "I, as well as businesses and cooperatives, am very happy that China has officially allowed the import of frozen durian, because for a long time we have mainly exported raw products, while agricultural products are seasonal. Processing products such as freezing, freeze-drying... will increase the value of exported products, diversify forms and markets."

However, Ms. Men emphasized that in the long term, businesses in the industry need to build an internal traceability process.

This means that the product of this batch will be traced back to growing area A or B to control the quality of the batch (including cultivation diary, care history, fertilization process, drug use...). On that basis, state management agencies will also find it convenient in food safety management and product traceability.

"The difficulty of the durian industry today is how to have consensus across the entire production chain, everyone working together to decode the challenges of the durian industry. As long as we do business properly, fruit products are strictly managed, and everyone does the right thing, we do not need to fear competition from Thailand, but on the contrary, Thailand "should be afraid". Because Vietnamese fruit has too many advantages in terms of land and climate; therefore, durian varieties originating from Thailand may have very good quality when grown in Vietnam."

Ms. Ngo Tuong Vy - General Director of Chanh Thu Fruit Import-Export Group Joint Stock Company

Regarding frozen durian exports, Mr. Trinh Dinh Duc - Deputy Director of Duc Hue Lam Dong Agricultural Co., Ltd. said that China will have higher requirements than fresh durian, the most important thing is that if there are orders, Vietnamese enterprises will be able to meet them.

"Thai frozen durian has been officially licensed to enter China for a long time, so we think they will apply the same criteria for Vietnamese durian," Duc analyzed.

Meanwhile, Mr. Nguyen Van Chau - Deputy Director of Lam Dong Department of Agriculture and Rural Development said that up to now, Lam Dong's agricultural sector has not received specific guidance documents from the Ministry of Agriculture and Rural Development on exporting frozen durian to China. However, the locality is still promoting for people to produce and grow durian in a safe manner, in accordance with the growing area code as well as the local crop planning.

According to Mr. Nguyen Van Chau, after receiving specific instructions from the Ministry of Agriculture and Rural Development, the locality will organize training and propaganda for people, businesses and cooperatives to produce durian according to export standards, meeting the requirements from China. From there, the export value of durian for Lam Dong in particular and Vietnam in general will be increased.

According to the Department of Agriculture and Rural Development of Lam Dong province, there are currently 23 enterprises and cooperatives in the area purchasing durian to supply the fresh fruit market, accounting for 88.8% of the total durian output of the province, equivalent to 110,042 tons of durian.

Along with that, businesses in Lam Dong province have also gradually switched to peeling and freezing processing with a capacity of 13,932 tons of fresh fruit/year (accounting for 11.2% of the total durian output of the province).

Source: https://baodaknong.vn/mo-vang-sau-rieng-loai-trai-cay-vua-cua-viet-nam-sau-rieng-dong-lanh-hieu-dung-de-xuat-khau-trung-bai-4-228532.html

![[Photo] Journalists moved to tears at the Memorial Service for the soldiers who died in Gac Ma](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/30/9454613a55c54c16bf8c0efa51883456)

![[Photo] National Conference "100 years of Vietnamese Revolutionary Press accompanying the glorious cause of the Party and the nation"](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/30/1cf6cd5c8a934ebfa347028dcb08358c)

![[Photo] General Secretary To Lam receives Chief of the Central Office of the Lao People's Revolutionary Party](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/30/140435f4b39d4599a3d17975dfb444c5)

![[Photo] A delegation of 100 journalists from the Vietnam Journalists Association visits the soldiers and people of Truong Sa island district.](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/30/0984a986227d4e988177f560d2e1563e)

Comment (0)