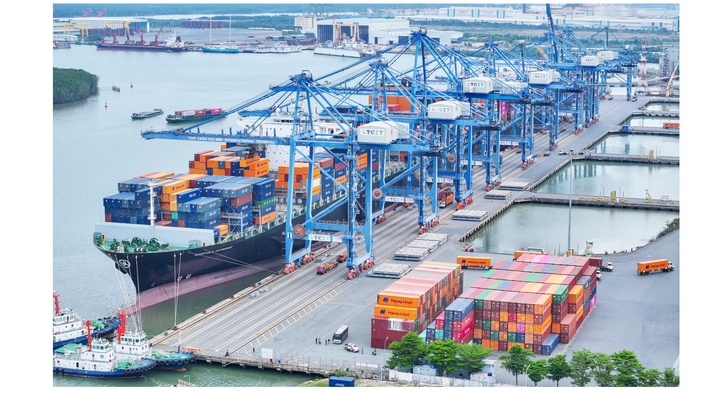

Vietnam's logistics currently contributes about 4-5% of GDP and creates jobs for more than 1 million direct workers.

According to ModorIntelligence, Vietnam’s logistics currently contributes about 4-5% of GDP and creates jobs for more than 1 million direct workers. It is forecasted that by 2030, the industry’s size could reach 71 billion USD.

Data from PwC and the Vietnam Logistics Business Association shows that Vietnam's LPI (Logistics Performance Index) only reached 3.3 points on a scale of 5, equivalent to the Philippines and lower than Thailand or Malaysia. Logistics costs account for about 17% of GDP, significantly higher than the average of 8-10% in developed economies .

These figures reflect a reality: despite its geographical and market advantages, Vietnam’s logistics operations capacity is still under great pressure due to its unsynchronized transport infrastructure, weak connections between transport modes, and especially low levels of technology application. Therefore, digital transformation is considered the key to unlocking new productivity for this important service industry.

"Technology" every meter of the wharf

At Saigon Newport Corporation - an enterprise that accounts for more than 90% of the import-export container market share in the Southern region, technology is not only a supporting factor, but also becomes the core foundation in port operations.

In just the first week of the Lunar New Year 2025, Tan Cang - Cat Lai Port handled up to 110,000 TEUs, equivalent to 1.5 million tons of cargo, up 9% over the same period last year. This impressive figure was operated by about 1,100 direct workers thanks to the automation of most of the stages of exploitation, dispatching, and container inspection.

Tan Cang Saigon started its transformation journey very early. In 2008, when the concept of "electronic port" was still unfamiliar, the enterprise mastered the TOPX planning software to optimize operations. By 2015, the TOPOVN container data management software was born, helping to shorten the delivery time from 2-3 hours to only 30 minutes/container, a breakthrough in port productivity.

In 2016, when the e-Port application was put into operation at Cat Lai, transport enterprises can check delivery conditions, customs clearance status, vehicle registration, electronic payment, and receive online delivery orders without having to go to the port. Combined with the Smart Gate automatic identification system, the vehicle inspection time at the gate is only 10-15 seconds, instead of 5-10 minutes as before.

Currently, e-Port has integrated virtual assistant Pi - a tool that uses artificial intelligence (AI) and natural language processing to respond to 100% of customer requests on the website, Fanpage and Zalo. Every day, thousands of business inquiries are answered immediately, reducing the load on the customer care center and optimizing operating costs.

Viettel Post and the "robot symphony" in modern logistics

In early 2024, Viettel Post put into operation the Smart Sorting Technology Complex at Exploitation Center No. 5, Quang Minh Industrial Park ( Hanoi ), the first model in Vietnam to synchronously combine autonomous robot technology (AGV), large sorting system Wheel Sorter Matrix and Cross-belt Sorter conveyor system.

Thanks to this combination, processing capacity increased by 40%, reaching 1.4 million postal items/day, bringing the total capacity of the entire Viettel Post system to 4 million postal items/day, equivalent to 50% of the country's e-commerce capacity. The error rate is almost zero, the entire delivery time is shortened to 8-10 hours, while operating costs are reduced by 40%, and personnel costs are reduced by 60%.

The system is monitored by Smart Warehouse, a smart warehouse that can track the journey of each order in real time. The "Digital Twin" model simulates the entire warehouse in 3D space, helping managers operate and forecast risks accurately down to the minute.

Viettel Post also masters the AGV robot technology "Made by Viettel Post" with 15% higher efficiency and helps save 25% of human resources compared to imported systems. Currently, 300 robots produced by the enterprise have been operating stably and are expected to expand to 1,200 robots in major centers in Hanoi, Da Nang, Ho Chi Minh City and Can Tho.

From a traditional postal enterprise, Viettel Post is moving closer to a model of fully automated logistics, where humans and robots work together to ensure optimal speed, accuracy and efficiency.

The success stories of Tan Cang Sai Gon or Viettel Post show that digital transformation is no longer an option, but a way to survive for logistics businesses. However, in the entire logistics industry, only a small percentage of businesses have achieved such strong progress.

Associate Professor Dr. Nguyen Thi Xuan Hoa, School of Economics - Hanoi University of Science and Technology, commented: "Limited investment resources, lack of technology-savvy personnel, and especially the lack of a specific roadmap are the biggest barriers for small and medium-sized enterprises in the digitalization process."

Ms. Pham Thi Lan Huong, Vice President of the Hanoi Logistics Association, believes that businesses should convert part by part, starting from the simplest applications, such as using cloud computing platforms (on-cloud) instead of writing expensive separate software. At the same time, it is necessary to build specific plans and KPIs for each department and ensure that all employees clearly understand their role in this roadmap.

Training and improving digital skills for the logistics workforce is also vital, because no matter how modern technology is, it still needs people to operate, monitor and innovate on that platform.

From port management to postal services, from sorting robots to smart warehouses, data Data is becoming the new "fuel" for the entire supply chain. If logistics is the blood vessels of the economy, then digital transformation is the heartbeat that helps that flow operate faster and more accurately. And on that journey, pioneering enterprises such as Tan Cang Saigon or Viettel Post are proving that technology not only changes productivity, but also reshapes the operating culture of a strategic economic sector in the digital age./.

Source: https://mst.gov.vn/chuyen-doi-so-trong-logistics-tu-cang-thong-minh-den-chuoi-cung-ung-so-hoa-197251113085702819.htm

![[Photo] Prime Minister Pham Minh Chinh meets with representatives of outstanding teachers](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/11/15/1763215934276_dsc-0578-jpg.webp)

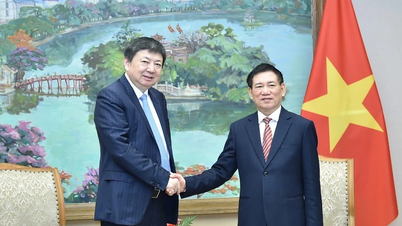

![[Photo] General Secretary To Lam receives Vice President of Luxshare-ICT Group (China)](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/11/15/1763211137119_a1-bnd-7809-8939-jpg.webp)

![[Photo] Panorama of the 2025 Community Action Awards Final Round](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/11/15/1763206932975_chi-7868-jpg.webp)

Comment (0)