Collaborative robots – A new lever for production efficiency.

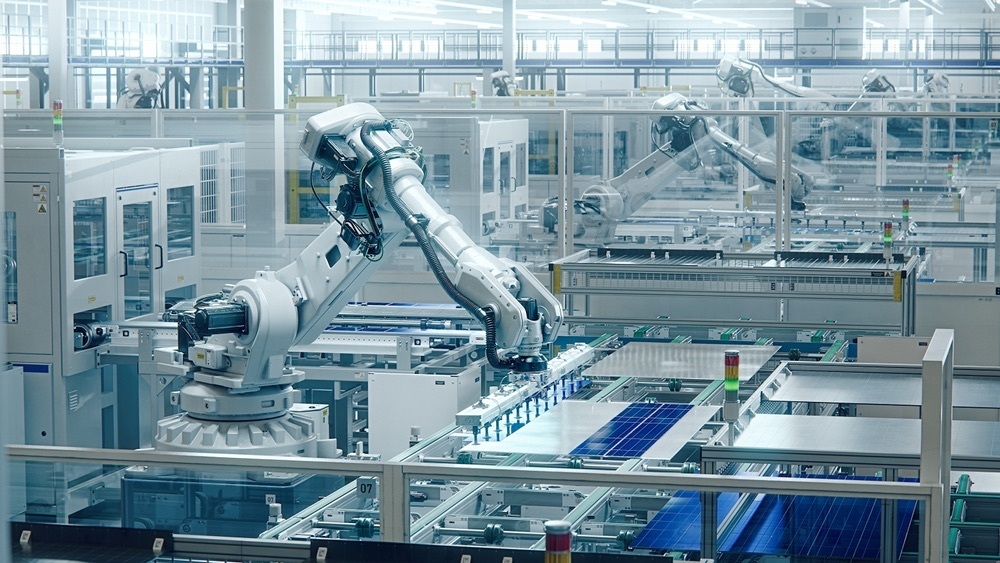

The world is witnessing a quiet but profound revolution in manufacturing.

These aren't giant robots confined in glass cages like before, but intelligent robot "colleagues" that can work alongside humans safely and efficiently. This is no longer science fiction, but a reality unfolding right before our eyes.

According to the latest report from McKinsey & Company, the global industrial robotics market has reached a record $16.5 billion in new installations, with more than 4.28 million robots operating in factories worldwide.

This figure not only reflects the industry's strong growth but also signals a new era in which robotics is no longer a luxury solution reserved for large corporations.

The biggest difference between the current wave of robots and previous generations is their ability to "cooperate" with humans.

These "collaborative" robots are designed to work alongside workers, not to completely replace human labor, but to support and enhance productivity. With advanced sensors and intelligent control systems, they can detect the presence of humans and adjust their movements accordingly, ensuring absolute safety.

The collaborative robotics market is booming with impressive growth rates. From $2.14 billion in 2024, this market is expected to reach $11.64 billion by 2030, equivalent to a compound annual growth rate (CAGR) of 31.6%.

This figure reflects the growing demand from businesses for flexible and easy-to-deploy automation solutions.

From pilot to full scale

One of the biggest challenges businesses face is not the pilot deployment of robots, but rather scaling up their application.

According to a McKinsey survey, approximately 40% of executives stated that while their robotics pilot projects were exciting and generated significant interest in manufacturing, their actual business value remained unclear.

The collaborative robot market is booming with impressive growth rates (Image: Genedge).

This doesn't mean robots aren't effective; the issue lies in the approach. Instead of viewing robots as mere tools to be purchased and used, businesses need to think about building overall automation capabilities. This represents a crucial shift in mindset from investing in equipment to developing operational capabilities.

Ujjwal Kumar from Teradyne Robotics shared: “The big difference is that traditional automation is a perfect solution made specifically for one application. The new generation of AI-integrated robots has standard products that serve a wide range of applications. You can deploy them for many applications through software and some differences in end-user tools.”

This means that instead of needing 100,000 different configurations like the previous technology, Universal Robots now only needs 6 configurations to serve 100,000 collaborative robot installations worldwide.

This is key to drastically reducing the total cost of ownership for the next generation of automation.

AI - The soul of the new generation of robots

The trend of integrating artificial intelligence into robots is growing stronger. By leveraging diverse AI technologies, robots can perform a wide range of tasks more efficiently.

Analytical AI enables robots to process and analyze large amounts of data collected by their sensors. This helps manage variability and unpredictability in external environments, in high-mix/low-volume production, and in public spaces.

Robots equipped with computer vision systems, for example, analyze past tasks to identify patterns and optimize their operation for greater accuracy and speed.

Computer vision systems play a crucial role in manufacturing robots (Photo: New Ocean).

Robot and chip manufacturers have recently been investing in developing specialized hardware and software that simulates real-world environments. This physical artificial intelligence allows robots to train themselves in virtual environments and operate based on experience rather than rigid programming.

Marc Theermann from Boston Dynamics explains: “Our vision is to create versatile robots that can go wherever humans can go, understand and interact harmoniously with their surroundings.”

And only when they can do all three of those things do you really have a versatile robot. For the last 30 years, we've been working on the "go anywhere" part, and we've become pretty good at that. Now, our robots can go almost anywhere humans can.”

The next two challenges they are trying to address are semantic understanding and manipulation. That's where they are spending most of their time.

These are the basic building blocks for the massive scale that people are anticipating for these types of robots.

Technology is changing the game.

Another significant breakthrough in the field of robotics is the Digital Twin technology.

Digital twins are virtual replicas of physical systems that mirror their real-world counterparts in real time. These models use data from sensors and machines to simulate the behavior and performance of their respective physical devices.

By providing a detailed digital representation, Digital Twin enables continuous monitoring, analysis, and optimization of the systems it replicates. This technology is particularly significant in mitigating the risks of robotic deployment.

As Ujjwal Kumar commented: “With Digital Twin, some of the risks you’re talking about disappear. Now you can deploy a new automation system in the virtual world, test it, refine it, and then from that very Digital Twin, you can download the code into the production environment.”

Digital Twins are virtual replicas of physical systems that mirror their real-world counterparts in real time (Image: Future).

This allows businesses to simulate and optimize production systems using Digital Twin before making actual capital investments. Companies can project a return on investment within one to three years and minimize integration risks with existing IT and OT systems, making robotic adoption smoother.

One growing trend in robotics that will continue to develop this year and beyond is the evolution of mobile manipulators, often referred to as MoMa.

These industrial robots are the result of combining tasks performed by robotic arms, such as grasping, lifting, or moving objects, with the ability of robots to navigate through space.

MoMa consists of an autonomous mobile robot (AMR - autonomous moving robot) integrated with a robotic arm equipped with appropriate tools.

Mobile handling robots can perform predefined production tasks on equipment or retrieve components from the production line or warehouse. This flexibility enables the automation of material handling to any location, introducing a new level of efficiency in manufacturing and warehouse management.

This mobility not only expands the robots' operating range but also allows them to adapt to changing factory layouts and meet the demands of mobile, flexible manufacturing.

Instead of being fixed in one location, MoMa can be deployed flexibly according to work needs, optimizing resource usage and improving overall efficiency.

One of the biggest barriers to robot adoption has always been the high initial investment cost, especially for small and medium-sized enterprises (Image: ITG Technology).

One of the biggest barriers to robot adoption has always been the high initial investment cost, especially for small and medium-sized enterprises.

Robot-as-a-Service (RaaS) robots are changing this by allowing companies to deploy robots on a subscription or rental basis instead of buying them outright.

The RaaS model offers several advantages including scalability, resilience, and flexibility, making it an ideal choice for search and rescue, environmental monitoring, manufacturing, agriculture, and space exploration missions.

RaaS helps companies scale up local production without significant capital risk, essentially “allowing producers who manufacture near home to move production closer to consumer markets without sacrificing cost efficiency.”

Challenges and opportunities ahead

Despite its positive outlook, the robotics industry still faces significant challenges. One of the biggest obstacles is the skills gap in the current workforce.

The current workforce lacks the expertise to deploy and manage automated robots. While this has led to labor shortages, one way to address this is to make robots more accessible through targeted education and training programs that equip workers with the right skills.

Technological advancements have far outpaced current educational and training frameworks. Workers often find themselves unprepared to handle modern robotic systems, from programming to maintenance.

This asymmetry slows the adoption of automation and exacerbates labor shortages as companies struggle to find qualified personnel.

Addressing this issue requires updating the education curriculum to include advanced robotics and automation technologies.

Industry partnerships can provide hands-on training and real-world experience through internships and apprenticeships. As Ani Kelkar from McKinsey noted: “When we surveyed executives about barriers, 61% of them reported that one of the main barriers was, even if they found a good business plan, they simply lacked the internal capacity to implement it.”

The current workforce lacks the expertise to deploy and manage automated robots (Photo: Mecalux).

To successfully deploy robots, businesses need to shift their approach from focusing solely on efficiency to prioritizing flexibility.

Ujjwal Kumar advises leaders to rethink automation through the lens of flexibility, not just efficiency. Traditional automation tools are built for high-volume, low-variability production environments. But today's market demands agility.

Social and labor impacts

A common concern regarding robots is their potential to replace human labor. However, the reality is that robots, especially collaborative robots, primarily supplement human labor rather than completely replace it.

Ani Kelkar emphasized: “This isn’t about replacing people. It’s about making work safer, more flexible, and more meaningful; it frees up workers to focus on higher-value tasks. There are so many repetitive tasks that don’t fully utilize the skills of our workforce.”

Automating these tasks while simultaneously investing in capacity building helps enhance the workforce and prepare it for the future of the operation.

In fact, according to Deloitte Consulting, 2 million new jobs could emerge in the manufacturing sector by 2025. This reflects the trend of robots creating more jobs than they eliminate, particularly in engineering, maintenance, programming, and systems operations.

Workforce challenges, including an aging population and declining interest in factory work, are driving the adoption of robots.

For example, the United States is short 400,000 welders, while Europe reported more than 200,000 job openings in the construction industry in 2020.

Robots fill these gaps by performing repetitive, physically demanding tasks, making them valuable assets for both small and large businesses.

Prospects for new technologies in the future.

Robotics technology is moving towards new breakthroughs. Generative AI is being integrated into robots to create more intelligent and adaptive behaviors.

These projects aim to create "ChatGPT moments" for Physical AI, where robots can understand and interact with their environment as naturally as humans.

Advanced sensor technology is making robots more sensitive to their surroundings.

Bionic sensors are being developed to provide a sense of subtlety similar to human skin. Advances in gripper technology utilize biology to achieve high gripping power with virtually no energy consumption.

Swarm robotics is opening up the possibility of deploying many small robots working together to accomplish complex tasks.

This approach offers several advantages including scalability, resilience, and flexibility, making swarm robots an ideal choice for search and rescue missions, environmental monitoring, manufacturing, agriculture, and space exploration.

Source: https://dantri.com.vn/cong-nghe/cuoc-cach-manh-robot-hop-tac-tuong-lai-cua-nha-may-thong-minh-20250905101445097.htm

![[Image] The tenacious fighting spirit of Vietnamese women's football](/_next/image?url=https%3A%2F%2Fvphoto.vietnam.vn%2Fthumb%2F1200x675%2Fvietnam%2Fresource%2FIMAGE%2F2025%2F12%2F17%2F1765990260956_ndo_br_4224760955870434771-copy-jpg.webp&w=3840&q=75)

![[Photo] Prime Minister Pham Minh Chinh receives the Governor of Tochigi Province (Japan)](/_next/image?url=https%3A%2F%2Fvphoto.vietnam.vn%2Fthumb%2F1200x675%2Fvietnam%2Fresource%2FIMAGE%2F2025%2F12%2F16%2F1765892133176_dsc-8082-6425-jpg.webp&w=3840&q=75)

![[Live] 2025 Community Action Awards Gala](/_next/image?url=https%3A%2F%2Fvphoto.vietnam.vn%2Fthumb%2F1200x675%2Fvietnam%2Fresource%2FIMAGE%2F2025%2F12%2F16%2F1765899631650_ndo_tr_z7334013144784-9f9fe10a6d63584c85aff40f2957c250-jpg.webp&w=3840&q=75)

![[Image] Leaked images ahead of the 2025 Community Action Awards gala.](/_next/image?url=https%3A%2F%2Fvphoto.vietnam.vn%2Fthumb%2F1200x675%2Fvietnam%2Fresource%2FIMAGE%2F2025%2F12%2F16%2F1765882828720_ndo_br_thiet-ke-chua-co-ten-45-png.webp&w=3840&q=75)

![[Photo] Prime Minister Pham Minh Chinh receives Lao Minister of Education and Sports Thongsalith Mangnormek](/_next/image?url=https%3A%2F%2Fvphoto.vietnam.vn%2Fthumb%2F1200x675%2Fvietnam%2Fresource%2FIMAGE%2F2025%2F12%2F16%2F1765876834721_dsc-7519-jpg.webp&w=3840&q=75)

![[Live] Closing Ceremony and Award Presentation for the "Impressive Vietnam Tourism" Video/Clip Creation Contest 2025](https://vphoto.vietnam.vn/thumb/402x226/vietnam/resource/IMAGE/2025/12/17/1765974650260_z7273498850699-00d2fd6b0972cb39494cfa2559bf85ac-1765959338756946072104-627-0-1338-1138-crop-1765959347256801551121.jpeg)

Comment (0)