|

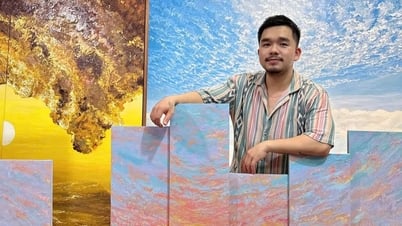

| Applying new machinery and technology is indispensable to improve the production efficiency of enterprises. Illustration photo: Van Gia |

To increase productivity and optimize operational efficiency, businesses are paying more attention to and applying more solutions to streamline production and improve the competitiveness of their goods and services.

Solutions to improve business performance

In the production process, there are actually stages where waste occurs. If businesses can limit this, production efficiency will increase.

Director of Hanh Gia Management Consulting Company Limited ( Ho Chi Minh City) Le Phuoc Van said: In wood production alone, in the past, up to 80% of production activities and production costs did not create added value, or were wasteful. Wastes are closely linked. Wastes include: overproduction, waste inventory, transportation and then damage, product defects... In addition, in production there are other waste issues such as: waiting, waste of operations or process deviations... Enterprises are forced to streamline to minimize these wastes.

Sharing the same view, Mr. Huynh Minh Quoc, General Director of Athena I&E Joint Stock Company (Ho Chi Minh City), an expert in applied lean management, said: Researching and applying a comprehensive lean 4.0 enterprise management system combined with planning and building a digital transformation strategy in the new situation is an appropriate and necessary step that enterprises need to research and implement. From there, it helps the human resource apparatus to be more streamlined, labor productivity to be higher, performance to be better, and rapid and stable development in both breadth and depth. "Digitalization" will help enterprises go fast and far thanks to the application of modern science and technology. Each enterprise has a different way of managing production, different processes, so it can proactively propose suitable solutions, achieving higher efficiency.

To produce lean and green production, managers or business leaders need to have a long-term mindset with a long-term roadmap, not a short-term leap; at the same time, pay attention to and train a team of human resources who share the same philosophy as themselves to increase efficiency when applying. |

Chairman of the Board of Directors of GC Food Joint Stock Company (Ho Nai Industrial Park) Nguyen Van Thu said: By increasing product productivity, enterprises can better implement strict requirements on environmental protection. The company aims to build an operating system capable of monitoring risks, ensuring transparency and creating conditions for long-term growth. The five factors: organization, supply chain, products, people and customers are the factors that enterprises base on to implement sustainable development solutions.

Increase applications to optimize production

Binh Tien Consumer Goods Manufacturing Company Limited (Biti's) has factories in Dong Nai , Ho Chi Minh City and other localities. According to Ms. Vu Le Quyen, General Director of the company, at the factories, Biti's has been optimizing area, reducing costs, improving productivity and shaping an effective operating model. The greatest achievement is the transformation in thinking and team capacity, the foundation for sustainable success. After more than 5 years of practicing lean, Biti's factory has optimized area, reduced costs, improved productivity and shaped a more effective operating model. Biti's will continue to apply lean and efficient production to produce new products and expand this model in the future.

Similarly, according to Mr. Nguyen Tan Loc, Chairman of the Board of Directors of GSB Steel Structure Joint Stock Company (Tan Trieu Ward, Dong Nai Province), the company is gradually greening its production process to improve business efficiency. In recent times, the company has always strived to find optimal construction solutions, both minimizing costs for partners and aiming to create sustainable, environmentally friendly works. GSB has cooperated with partners from Australia to take advantage of their technology and advantages to apply to its production process, both creating high efficiency in work and providing green factory construction solutions for partners.

Sharing his experience, according to Mr. Le Phuoc Van, to produce effectively, enterprises need to go through 3 stages. The first is investing in equipment, using external forces to increase productivity; the second is standardizing production, standardizing resources and finally innovation. Currently, most enterprises often focus on technological equipment and do not pay due attention to the remaining factors. That means enterprises have focused too much on external forces and forgotten internal forces, which can proactively adjust and change themselves. The human factor is the most important, how will people choose the right equipment, operating and production processes to optimize costs because the productivity index is the issue that enterprises aim for in the end.

Van Gia

Source: https://baodongnai.com.vn/kinh-te/san-xuat-kinh-doanh/202508/doanh-nghiep-huong-den-san-xuat-tinh-gon-6fa0031/

![[Photo] Prime Minister Pham Minh Chinh attends a special art program called "Hanoi - From the historic autumn of 1945"](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/8/15/c1c42655275c40d1be461fee0fd132f3)

![[Photo] Red and yellow stars at the launching ceremony of the program "Moving Forward with Vietnam"](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/8/16/076df6ed0eb345cfa3d1cd1d7591a66f)

![[Photo] The special solidarity relationship between Vietnam and Cuba](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/8/15/5f06c789ab1647c384ccb78b222ad18e)

![[Photo] Firmly marching under the military flag: Ready for the big festival](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/8/15/86df2fb3199343e0b16b178d53f841ec)

![[Photo] Prime Minister Pham Minh Chinh talks on the phone with Cambodian Prime Minister Hun Manet](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/8/15/72d3838db8154bafabdadc0a5165677f)

![[Photo] National Assembly Chairman Tran Thanh Man attends the inauguration ceremony of President Ton Duc Thang Memorial House](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/8/16/23555950872d428a8708a1e2f94cbf59)

Comment (0)