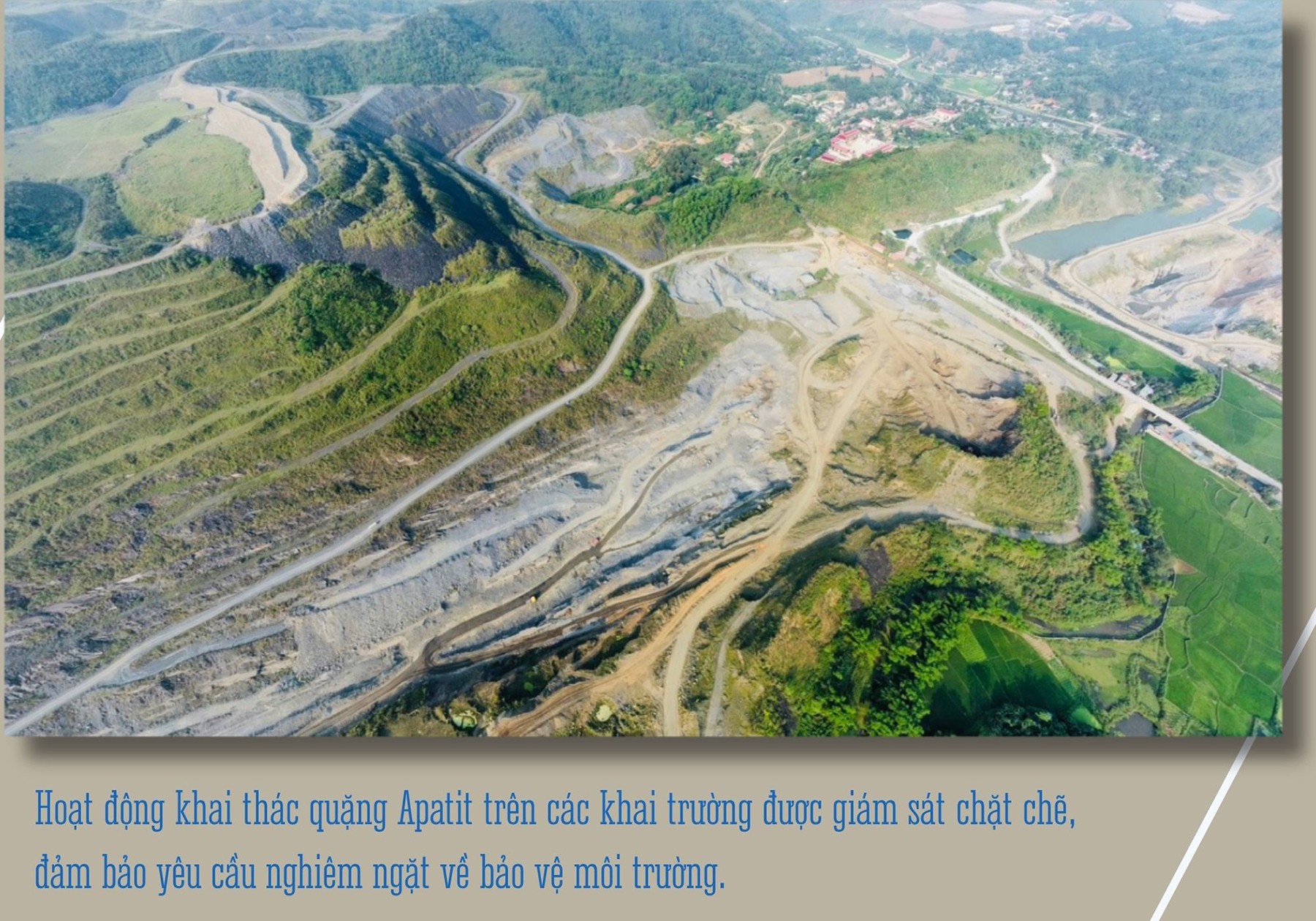

Lao Cai has great potential for minerals with nearly 300 mines and mining points belonging to 17 mineral groups such as: Sin Quyen copper, Quy Sa iron, white limestone (Luc Yen, Yen Binh), notably Apatite with reserves of billions of tons, along with over 400 mineral mine points for common construction materials. This is an invaluable resource of the country, therefore, the development of the mineral exploration, exploitation and deep processing industry is associated with rational, economical, effective and environmentally friendly use.

Previously, the filtration stage of Tang Loong Processing Plant (Apatit Vietnam Co., Ltd.) used a disc-type vacuum filter. After using the disc filter, there were limitations such as: the flow of the filtered ore sludge circulating back to the concentration tank was more than designed due to ineffective filtration; the process of concentrating the ore was consumed a lot; the ore concentrate product was lost on the way to consumption, affecting the landscape and environment...

From the above situation, to stabilize the technology, increase the productivity of the filtering stage, reduce the humidity of the filtered ore; reduce the cost of electricity, repair, noise of the filtering stage; reduce the loss of selected ore in the overflow water of the ore concentrate tank, the factory has innovated the filter press equipment to replace the vacuum filter of the ore concentrate filtering technology line.

This solution has brought practical results, that is, the yield of refined ore products increased by >1%, due to no loss of product through the refined ore concentration tank. The power consumption was reduced by 5kw/ton of refined ore. Using the filter press, the moisture content of refined ore was reduced by 3%, minimizing the loss of resources and the impact on the environment and landscape.

This is just one of many initiatives and innovative solutions in technology and equipment in mining, production and processing applied by Apatit Vietnam Company Limited to increase productivity, ensure safety, save resources and minimize environmental impacts, contributing to the stable and sustainable development of the Company over the past time.

As a business operating in the mining sector, which is prone to environmental pollution, Sin Quyen Copper Mine Branch, Lao Cai - Vimico has prioritized investment resources to innovate technology, increase mining and transportation equipment, along with good management and operation of drilling and blasting, loading, transportation, maintaining the stability of the mineral processing plant chain, so the copper concentrate products produced are of high quality and protect the environment...

In particular, to ensure safety and prevent environmental incidents during the production process, Sin Quyen Copper Mine Branch has been approved by Vinacomin to invest in the construction and execution of the "Project for waterproofing the waste lake of the Mineral Selection Plant".

After the project is completed, all the sludge after selection will be stored in a reservoir, ensuring standards and limiting the amount of wastewater seeping into the environment.

Together with Apatit Vietnam Co., Ltd. and Sin Quyen Lao Cai Copper Mine Branch, mineral exploitation and processing enterprises in the province have proactively invested in technology and equipment to reduce emissions and limit impacts on the environment. Wastewater treatment systems, dust filtration systems, conveyor belt covers, water recovery and reuse in the production process have been applied at a number of facilities.

In addition, the enterprise fully implements environmental records, commits to depositing environmental restoration funds and deploys incident prevention plans to ensure labor safety.

Ensuring the harmony of economic development with environmental protection has been one of the province's consistent goals in recent years. In response to the need to effectively exploit mineral resources for industrial purposes, the province has proactively improved management mechanisms, strengthened supervision, guided enterprises in technological innovation, and promoted environmental restoration after exploitation to ensure sustainable development.

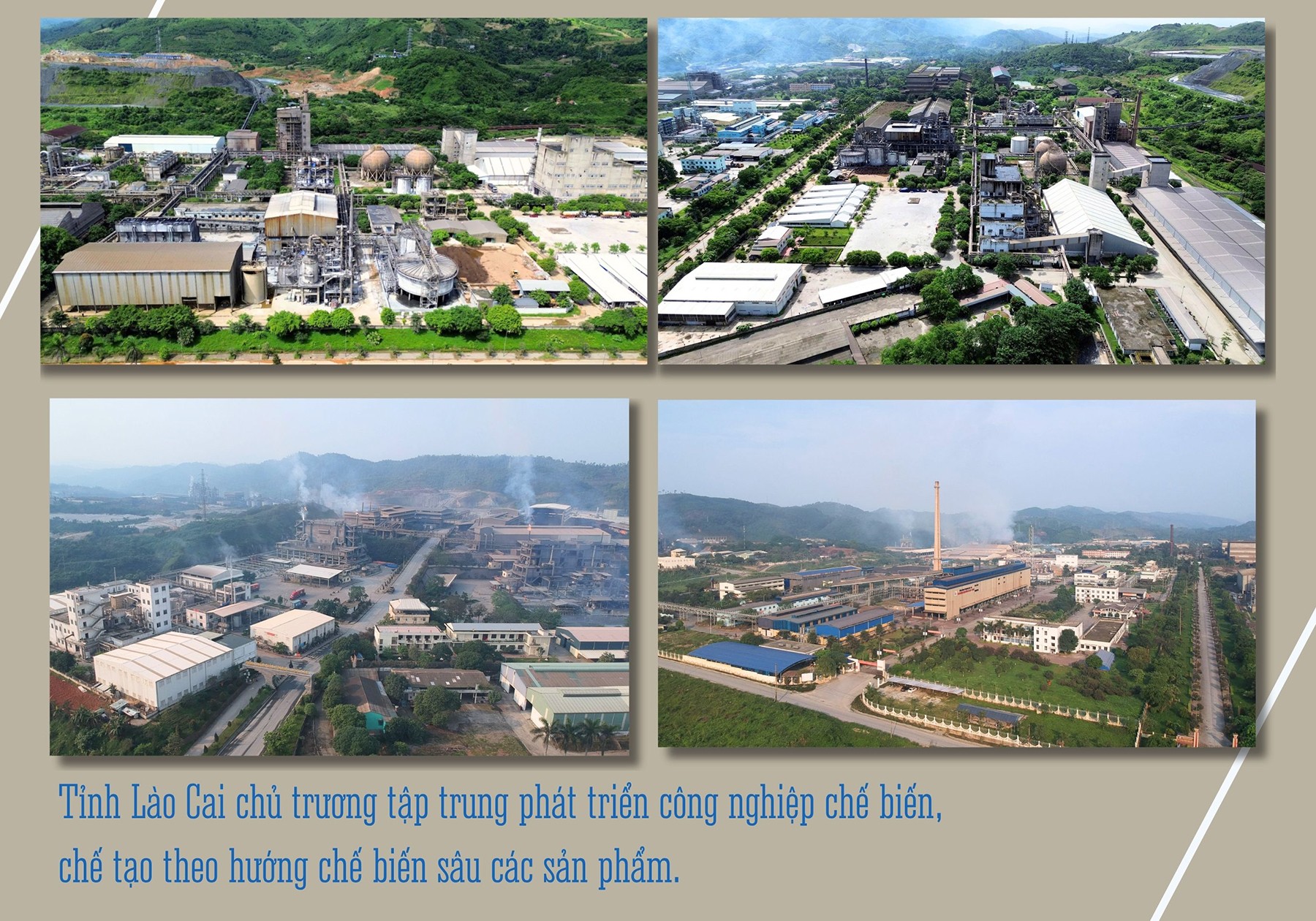

Resolution of the 1st Lao Cai Provincial Party Congress, term 2025 - 2030 emphasized the viewpoint of "developing environmentally friendly industry with high technology content and added value".

The province focuses on developing the processing and manufacturing industry in the direction of deep processing of products and expanding and developing the post-metallurgical, chemical and fertilizer industries associated with the strategy of exploiting and effectively using important minerals such as apatite, copper, iron, stone, rare earth, graphite, precious stones, white stones, especially forming a metallurgical - chemical industrial production chain to serve key national projects.

Continue to develop industrial zones and clusters in the Northern region, gradually converting Tang Loong industrial zone into a green industrial zone; plan, expand and invest in a synchronous and modern Southern industrial zone, striving to have an additional 2,000 hectares of industrial land and industrial clusters by 2030. Prioritize attracting the development of high-tech, environmentally friendly industries.

From this consistent orientation, the province has directed departments and branches to review and assess the impact of industrial project development on social security. New investment projects are required to assess environmental impacts and have environmental treatment solutions before investment is approved. Assess the current environmental status of all existing production facilities, especially in industrial parks and clusters; inventory the main sources of pollution, periodically monitor and analyze to propose effective treatment solutions.

Gradually concentrate production in industrial zones and clusters. Construct wastewater and solid waste treatment facilities in industrial zones and clusters. For mineral exploitation activities, in addition to environmental protection measures prescribed by the State, there should be measures to force enterprises to carry out environmental restoration work immediately after the end of exploitation.

For existing production facilities, it is necessary to modernize each part and innovate equipment technology at each stage and each part of the production line, gradually modernizing the entire line to improve product quality, reduce costs, and increase product competitiveness. For new investment projects, it is necessary to consider applying modern, advanced technology suitable for each stage of development, not importing outdated technology and equipment.

Gradually eliminate energy-intensive technologies; encourage the use of clean technologies that cause less environmental pollution. Apply tax exemption and reduction policies for enterprises investing in technological innovation and equipment, tax exemption and reduction for capital for technological innovation research and products that meet quality standards to replace imported goods within a certain period of time.

Mineral exploitation and processing associated with environmental protection in Lao Cai has had positive changes, demonstrating the determination of the government and the sense of responsibility of enterprises. Continuing to promote institutional improvement, applying science and technology and increasing community participation will be the key for Lao Cai to effectively exploit resources, ensure living environment and sustainable development.

Source: https://baolaocai.vn/khai-thac-che-bien-khoang-san-gan-voi-bao-ve-moi-truong-post886733.html

![[Photo] General Secretary To Lam receives Vice President of Luxshare-ICT Group (China)](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/11/15/1763211137119_a1-bnd-7809-8939-jpg.webp)

![[Photo] Panorama of the 2025 Community Action Awards Final Round](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/11/15/1763206932975_chi-7868-jpg.webp)

![[Photo] General Secretary To Lam receives Governor of Kanagawa Province (Japan) Kuroiwa Yuji](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/11/15/1763204231089_a1-bnd-7718-5559-jpg.webp)

Comment (0)