|

Companies in the AI server supply chain are ramping up production in the US at the invitation of President Donald Trump. Photo: Nikkei . |

At Foxconn's manufacturing center in Houston, Texas, hundreds of engineers and construction workers are working around the clock to expand AI server production lines, aiming to improve the proportion of GPUs and motherboards made in the US.

Currently, more than 90% of the above components are produced in Taiwan. However, sharing with Nikkei , a Foxconn leader emphasized that Houston is the company's "top priority".

The strategy of producing GPUs for AI servers in the US could help Foxconn improve its supply chain resilience amid geopolitical uncertainty. This could also be seen as a victory for US President Donald Trump, who has pursued a “Made in the USA” strategy through his recent tariff policy.

Ecosystem Development Strategy in the US

According to Nikkei , the “heart” of the AI server comes from the GPU and circuit board. Foxconn and Wistron are the companies that manufacture these parts for Nvidia, which require large engineering resources. The development process also requires close cooperation with TSMC, another important partner of Nvidia.

Foxconn has more than 1,000 engineers developing AI systems for Nvidia. Both Foxconn and Wistron plan to expand AI server production lines in Texas over the next 15 months, while TSMC aims to produce AI chips in Arizona this year.

SK Hynix, which makes memory for Nvidia, is moving production of high-bandwidth memory (HBM) chips to Indiana. Components and mechanical suppliers Delta Electronics, Lite-On Technology, Chenbro and Foxlink, and assembly partners Quanta Computer, Wywinn and Inventec are also building or expanding production in the United States.

|

Foxconn's AI server on display at Computex 2025 on May 20. Photo: Nikkei . |

The latest wave of expansion suggests that the supply chain for manufacturing AI servers — some of the world’s most complex devices — could be Mr. Trump’s first victory in his goal of bringing high-tech manufacturing back to the United States.

Simon Lin, chairman of Wistron, which supplies GPU modules and circuit boards to Nvidia, said the uncertainty over Trump’s tariffs made building an AI server manufacturing facility in the U.S. “more urgent.” The Taiwan-based company aims to complete the Texas factory in at least the next 12 to 15 months.

Pegatron, another Nvidia partner, said it will soon finalize plans to build an AI server manufacturing facility in the next 1-2 months, expected to be located in Texas.

The strategy to develop an AI server ecosystem in the US accelerated after Nvidia announced a plan to invest $500 billion to build supercomputers in the country.

The announcement comes weeks after Mr Trump first announced the tariffs in April. Since then, at least eight suppliers to Nvidia have announced new investment plans in the US, with six partners planning to build facilities in Texas.

New investment trends

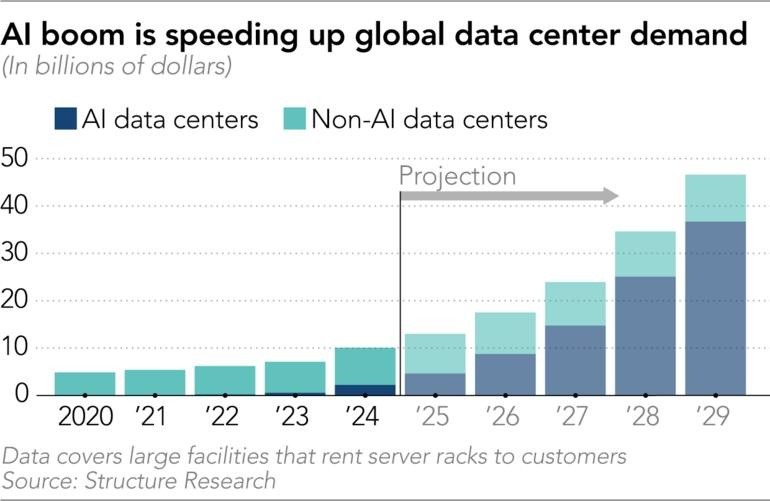

AI data centers will become a new development trend of the technology industry from 2022, when ChatGPT and generative AI tools will explode. Data centers are also an important aspect of the AI strategy of some countries, while the consumer electronics industry is slowing down due to low demand.

John McWilliams, director of data center insights at Cushman & Wakefield, said demand for AI data centers will surpass traditional data centers as early as 2026.

“We need to keep in mind that AI is still in its infancy. The landscape is only set in 2022 with ChatGPT, which is not that far away. Given the strong growth momentum over the past three years, we expect exponential growth to continue,” McWilliams said.

Baron Fung, data center analyst at Dell'Oro Group, also emphasized that the race to invest in AI infrastructure is very fast. He estimates that the amount of investment in AI infrastructure in 2025 will reach nearly $ 600 billion , up sharply from 2024 ( $ 457 billion ), with North America accounting for more than 50%.

|

Forecast of investment in traditional data centers and AI data centers through 2029. Photo: Nikkei . |

Currently, the Nvidia GB200 NVL 72 is the world's most powerful AI server system, one of the most complex pieces of technology. The system contains more than 1.2 million chips, components and other components, along with 130,000 billion transistors and more than 3 km of copper cable.

Each server cabinet weighs 1,800 kg and consumes about 1,000 kWh of electricity in 8 hours, three times the average Taiwanese household's electricity consumption in a month. Given their size, mass and $3 million price tag, manufacturing them in the US seems more logical than the iPhone.

Compared to AI servers, iPhone manufacturing requires a large amount of labor, while many components have profit margins of less than $1 . The US is also home to many of Nvidia’s major customers, such as Microsoft, Meta, Google, and AWS, which are all investing heavily in AI data centers.

Why Making AI Chips in the US is Easier Than iPhones

TSMC’s $165 billion investment in Arizona could be crucial to its plans to expand its supply chain in the U.S. Speaking to Nvidia CEO Jensen Huang in early June, TSMC CEO CC Wei said the company’s top priority is to expand its manufacturing capacity quickly enough to meet Nvidia’s surging demand for AI chips.

TSMC's investment in Arizona could serve 50% of US customers' chip demand by 2032, up from virtually none in 2024, according to Bernstein Research estimates.

That doesn’t mean all the components that make up AI chips will be made in the U.S., though. Huang acknowledged in May that some manufacturing and supply chain operations are necessary, but that it’s not possible to move everything to the U.S.

Specifically, production of some components such as substrates, quick-disconnect connectors, printed circuit boards (PCBs) still takes place in Asia due to cost and environmental protection issues, some industry executives cited.

|

Foxconn Chairman Young Liu (left) and Nvidia CEO Jensen Huang on May 20. Photo: Nikkei . |

TJ Tseng, chairman of Unimicron, one of the major chip substrate and PCB manufacturers, said his company had considered investing in the US, but had no concrete plans due to the lack of substrate supply chain and customer demand.

Shen Ching-Hang, president of thermal solutions provider Asia Vital Components, one of Nvidia's main partners, said the company is considering building a production line in the US but only for prototypes, not for mass production.

While not all of it, shifting production of some key AI server components to the US is still a win for the Trump administration. Compared to consumer electronics like the iPhone, Nvidia’s major customers, including Amazon, Google, Microsoft, etc., have the resources and means to support the shift in supply chains.

“Even if they see higher costs in the US supply chain, they are willing to ‘bear it’ because they have a lot of money. Gaining market share is very important and the number one priority, cost is just a secondary factor,” analyst Baron Fung emphasized.

Source: https://znews.vn/chien-thang-dau-tien-cua-ong-trump-khong-den-tu-iphone-post1560421.html

Comment (0)