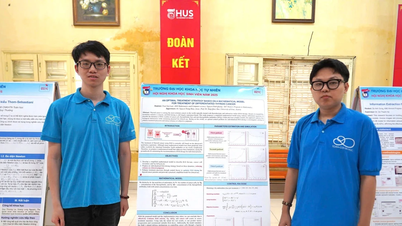

Surpassing hundreds of projects, a group of students from Hanoi University of Civil Engineering won first prize in the 2025 student startup idea contest organized by the Ministry of Education and Training. The authors of the project are 3 final year students from the Faculty of Construction Materials: Dam Duc Son, Nguyen Quang Minh and Doan Dinh Huy.

Team leader Dam Duc Son said that, faced with the complicated situation of many fires occurring recently, along with the increase in industrial waste, the group came up with the idea of creating a product to solve those urgent problems.

The main idea of the project is to use industrial waste Cenospheres (replacement of sand) and fly ash in the coal burning process of thermal power plants to create fireproof and insulating mortar. This special mortar product will be sprayed on steel structures (basic parts divided from structures in reinforced concrete or steel structure works) in warehouses and industrial buildings. This method helps increase the insulation time, thereby increasing the load-bearing capacity of the warehouse and providing more time to put out fires or evacuate people, helping to reduce damage from fires and explosions.

“We have studied many types of materials, and through lessons at school, we learned about Cenospheres - a non-flammable inorganic material, a component of fly ash produced during the coal burning process at thermal power plants. The group decided to use Cenospheres waste because they have a structure consisting of tiny hollow parts inside, are light - suitable for insulation materials. The group believes that the structure of Cenospheres will increase insulation and fire resistance for mortar products and after many tests, the product was produced,” Son said.

The mortar components of the group include: Cenospheres (replacement for sand), ash, cement, reinforcing fibers, additives and water. The mixing ratio of each type is the secret that makes the difference for the product.

Through practical testing, the group's mortar products have superior heat resistance compared to conventional mortars made from sand or other materials.

“When the front side was heated for 5 minutes, the results showed that when the temperature of the fire contact surface was 300 degrees Celsius, the back side of the group's product remained almost unchanged compared to the original, at 30-30.5 degrees Celsius. Meanwhile, the temperature of the back side of the conventional mortar (using sand and following the standard mix ratio) increased from 34 to 85 degrees Celsius. This shows the superior insulation ability of the product.

Not to mention, the prices of fireproof and insulating materials on the market are quite high, making it difficult for many businesses to access them," Son said, adding that the group's products have a better price than other fireproof and insulating mortars on the market by about 20%.

To get the product today, the team spent 1 and a half years of persistent research and testing from the time of the idea.

The most difficult part was finding information, because there are still few studies on the physical properties of Cenospheres in Vietnam. “At first, the group had difficulty in researching this material, while having to clearly identify the physical properties of the material to be able to decide on the appropriate mortar mix ratio. However, after receiving support from the instructor, the group made progress to perfect the product,” Son said.

In addition to the laboratory, the team also conducted experiments at two locations outside Hanoi to "measure" adhesion; resistance to destruction, cracking,... and received very good results.

According to the group of students, there is currently no unit researching and selling products from this material in Vietnam. “Cenospheres is a fairly new material, is waste and is completely available in Vietnam so the cost will not be high,” the group of students are confident in their direction.

With this project, the group of young people hope to not only help reduce human and property damage when fires and explosions occur, but also contribute to promoting industrial development, helping to reduce the amount of ash and toxic gases released into the environment; at the same time, reduce the need to use and exploit natural resources, helping to save investment costs for businesses.

“We are very happy to be able to solve the waste problem and create a new solution to reduce investment costs in fire prevention and fighting, increasing safety for constructions,” Son said.

Associate Professor Dr. Le Ba Danh, Deputy Head of the Department of Science and Technology of the Hanoi University of Civil Engineering, said that this is a very practical project for life, especially in the current context. “Cenospheres are a waste, but are very effectively applied in the production of lightweight concrete and modern construction materials thanks to their special properties such as lightness, insulation, sound insulation and good mechanical strength. This material will open up great potential and prospects for the student group's project,” said Mr. Danh.

The group of young people said that in the future, they will continue to research and complete the project, develop more wall and floor tiles, etc. made from this mortar product and can be used for civil houses.

Source: https://vietnamnet.vn/nhom-sinh-vien-xay-dung-ho-bien-phe-thai-thanh-vat-lieu-chong-chay-cach-nhiet-2394441.html

Comment (0)