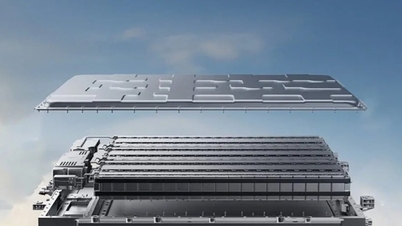

Chery Automobile has unveiled a prototype solid-state battery module with an energy density of up to 600 Wh/kg, significantly higher than that of common electric vehicle batteries today. This density, it claims, could extend the driving range to about 1,300 km per charge, while also improving safety and charging speed. However, high manufacturing costs and material challenges remain major barriers to commercialization.

600 Wh/kg and what it means for operating range

Energy density is a key variable that determines the range and weight of a battery pack. Compared to the nickel–cobalt–aluminum (NCA) batteries in some Tesla models, which typically reach 200–260 Wh/kg, the Chery prototype’s 600 Wh/kg is a significant jump. In theory, higher density allows for battery pack weight reduction while maintaining capacity, or for the same weight while extending range.

According to Chery, at 600 Wh/kg, the range could reach around 1,300 km per charge. This figure surpasses many current models; by comparison, the Lucid Air Grand Touring gets over 500 miles per charge. The difference shows the potential of high energy density in real-world applications.

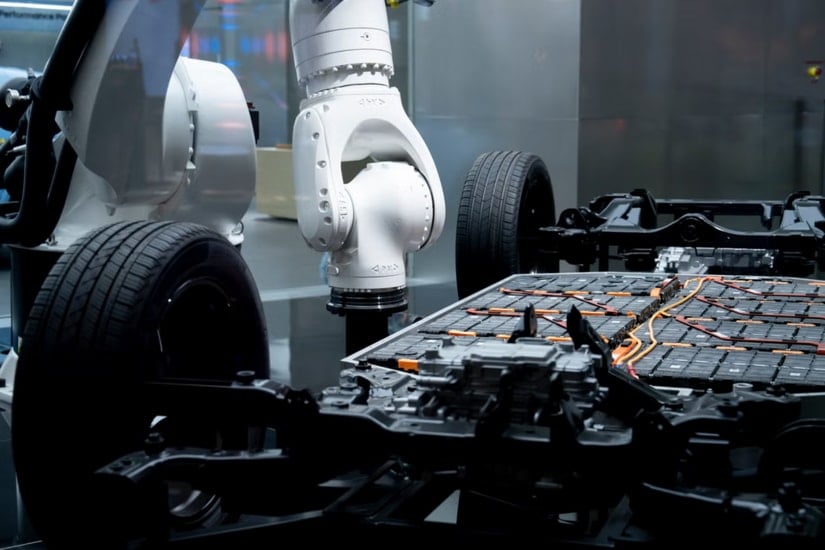

Puncture safe, flexible in battery pack design

One key advantage of solid-state batteries is safety: solid electrolytes are resistant to fire, reducing the risk of fire and uncontrolled overheating. According to Chery’s testing, the modules can be pierced or drilled without igniting or producing smoke. This is an important difference from many liquid-based battery systems, where mechanical failure can easily trigger a thermal reaction.

The solid electrolyte structure also opens up more flexible form factors, allowing manufacturers to arrange battery packs in complex shapes to optimize chassis space. If implemented, this could bring benefits in packaging, mass distribution, and cooling system layout efficiency.

Fast charge 4–6 times and expect durability

Chery says solid-state batteries can charge 4–6 times faster than traditional lithium-ion batteries, thanks to a stable solid environment that supports the flow of lithium ions. Solid-state technology is also expected to improve performance and extend life over time. However, detailed figures for charge-discharge cycles or degradation rates are not included in the announcement and will need to be verified when moving towards commercial products.

Cost, sulfide materials and barriers to commercialization

Despite the advantages of density, safety and fast charging, solid-state batteries currently have an estimated production cost of about 2.8 times higher than the popular lithium-ion technology. In addition, the sulfide materials involved in the solid electrolyte system are considered complex to manufacture. These two factors are significant barriers to scaling up and reducing costs.

Progress toward commercialization therefore depends on the ability to simultaneously solve two problems: process optimization and materials supply chain. If prototypes can overcome this hurdle, the benefits in range, charging speed, safety, and design potential could be transformative for electric vehicles.

Tech race: patents show warming up

It's not just Chery that's making significant investments in solid-state. Toyota currently leads the field in terms of patents, with more than 1,700 patents, reflecting the intensity of competition in this field. According to Popularmechanics, if prototypes are soon commercialized, solid-state technology could be the next tipping point for the electric vehicle industry.

Summary of key data by publication/source

| Category | Information |

|---|---|

| Module energy density | Up to 600 Wh/kg (Chery) |

| Compare references | NCA on some Tesla models: 200–260 Wh/kg |

| Potential range | About 1,300 km per charge (according to Chery) |

| Charging speed | 4–6 times longer than traditional lithium-ion batteries |

| Safety | Penetration/drilling without ignition or smoke generation (Chery test) |

| Current production costs | About 2.8 times higher |

| Related patents | Toyota has more than 1,700 patents |

Conclude

Chery’s 600 Wh/kg solid-state battery prototype paints a compelling picture of the future of electric vehicles: longer range, faster charging, and greater safety. However, the cost and sulfide material hurdles may determine how quickly the technology can be brought to commercial vehicles. If overcome, solid-state could become the next generation of battery platforms, reshaping how electric cars are designed and operated in the coming years.

Source: https://baonghean.vn/pin-the-ran-chery-600-whkg-tiem-nang-1300-km-10312648.html

![[Photo] Close-up of heavy damage at the school located on the banks of the Ban Thach River](/_next/image?url=https%3A%2F%2Fvphoto.vietnam.vn%2Fthumb%2F1200x675%2Fvietnam%2Fresource%2FIMAGE%2F2025%2F11%2F26%2F1764152130492_ndo_bl_img-8188-8805-jpg.webp&w=3840&q=75)

![[Photo] VinUni students' emotions are sublimated with "Homeland in the Heart: The Concert Film"](/_next/image?url=https%3A%2F%2Fvphoto.vietnam.vn%2Fthumb%2F1200x675%2Fvietnam%2Fresource%2FIMAGE%2F2025%2F11%2F26%2F1764174931822_10-3878-jpg.webp&w=3840&q=75)

![[Photo] Opening of the 28th Session of the Hanoi People's Council](https://vphoto.vietnam.vn/thumb/402x226/vietnam/resource/IMAGE/2025/11/26/1764155991133_image.jpeg)

Comment (0)