Placed next to porcelain bowls from Japan and China, countries famous for their ceramic industry, Vietnamese bowls are not inferior. "Suddenly I thought about the crude ceramic bowls at home, a strange feeling welled up in my mind. A burning desire to grow up to make beautiful ceramic bowls, even more beautiful than their bowls...", Mr. Ly Minh Long recalled. That year, he was only 12 years old.

But without waiting to "grow up", returning from the exhibition, the boy Ly Ngoc Minh buried his head in the "research room", which was actually a small corner in the family's kiln, learning about glaze, color... Admitting that he was only a "third grader from a village school", the ability to understand, prepare, research experiments, find the right glaze color; then how to fire without tilting, clear patterns, what color to produce... all had to be self-taught, read many books in the fields of chemistry, geology, physics and spent a lot of time researching, pondering, testing...

Mr. Minh said: "The ceramic industry has its own characteristics. In addition to many questions that can only be answered by science and technology, which at that time was very backward compared to the world, the more difficult thing was to learn from heaven and earth, from nature. I joked that an iron bird (airplane - PV) had to learn from real birds to know how to fly, but an eagle knows how to fly by birth, it doesn't need to be learned. We learn from nature like that. When facing difficulties, getting closer to nature, learning how to observe and analyze using scientific methods, will reveal many things. We must apply science and technology to compete with them on price but still maintain our own unique features" - Mr. Minh concluded.

At the age of 16, he replaced his mother in managing several pottery kilns, became the owner of the business and was filled with the hope of escaping poverty, "there was no other way but to research to get higher quality glaze colors".

Together with his friend Duong Van Long, the two spent day and night researching how to mix colors of glaze to paint ceramic products without having to import them from Japan or England. Heaven did not disappoint them, the technology to mix and create "Western glaze" colors was successful within a year.

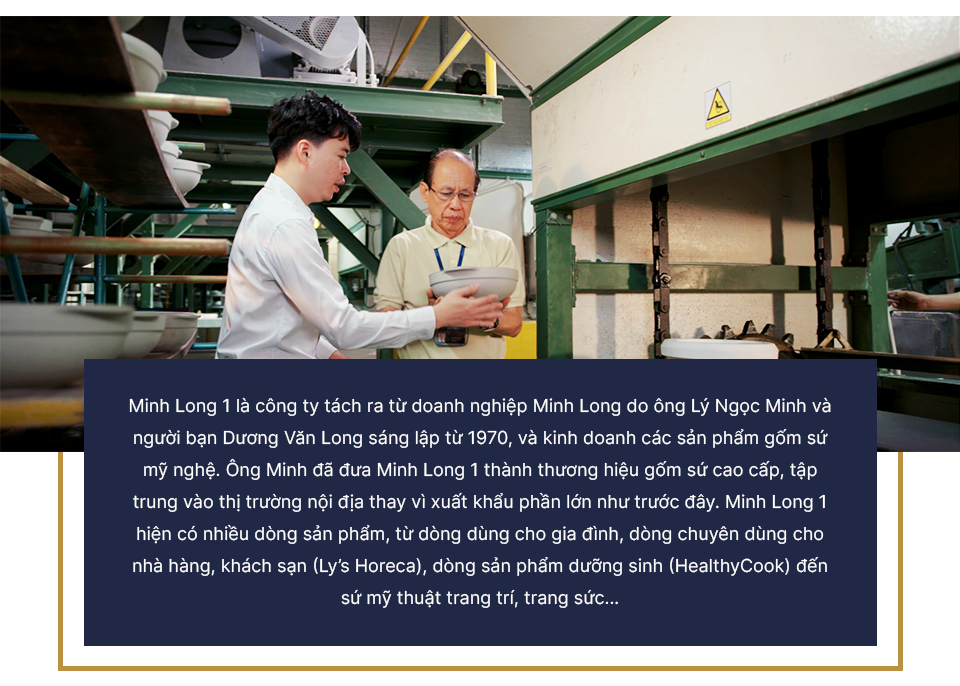

In 1970, the two decided to establish a company to use the "Western glaze" color they had successfully researched to create the first batches of fine art ceramics. Two years after its establishment, the batches of sparkling, shiny fine art ceramics from Minh Long ceramic kiln were officially exported and were immediately welcomed by the market.

Many people who used to like foreign ceramic products come back to buy Minh Long 1 products.

Nguyen Nga

But the fun was short-lived. After 1975, the world's ceramic export production slowed down. Difficulties piled up, Mr. Minh had to switch to making toothpaste, brewing wine, and growing papaya to make a living and nurture his ceramic ambition. He was the one who brought the Taiwanese papaya variety to grow in Binh Duong, which produced fruit close to the ground and had a denser flesh than the traditional variety. Thanks to papaya, he was able to accumulate 8 taels of gold to return to ceramics.

The following decade was a difficult period, not only for Minh Long but also for the whole country after reunification. However, the desire to bring Vietnamese ceramic products to the world never stopped flowing in the hearts and minds of the people of the ceramic region.

In 1990, Minh Long 1 became one of the first private enterprises to receive an export license, which was also a milestone marking the official revival of the Minh Long 1 ceramic brand. Five years later, export turnover increased continuously, and Minh Long 1 soon built a solid market for itself in many European countries. 1995 was considered the "peak" of Minh Long 1's export career with 98% of products being exported, realizing the dream of bringing Vietnamese ceramic products abroad of businessman Ly Ngoc Minh.

"If you want to successfully bring bells to foreign countries, you must try to bring sophisticated products that other people do not have. Do not try to bring something that many people already have. It will be difficult to gain market share. Or maybe other people already have that product. You have to improve it in a different way, better than others, to survive" - Mr. Minh said about his secret to conquering the market.

Up to now, after 50 years of establishment, Minh Long 1 Company Limited has affirmed its position as the number 1 domestic ceramics company and has set the ambition to be in the top 10 international ceramics companies by 2030. In a conversation with us, Mr. Ly Ngoc Minh said that many people call his 30-year journey a journey of lighting, maintaining and passing on the fire of the third descendant of the Ly family, a family with a tradition of building a career and success from the land.

As for Mr. Minh, what helped him make that journey was his strange, inexplicable passion for ceramics. "What makes me most satisfied is that each product I create has a soul and culture in it. A product without a soul is like a person without knowledge, without beingeducated to grow up. A product with a soul will naturally tell the story of Vietnamese ceramics," said Mr. Minh.

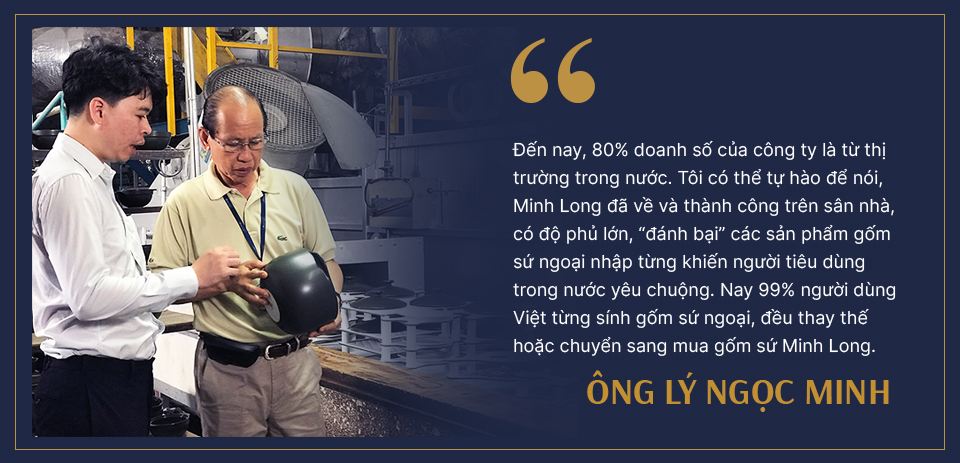

But the greatest desire of businessman Ly Ngoc Minh is not only to conquer foreign markets. Vietnamese ceramics not having a foothold in the domestic market has ignited a passion in him and that fire has never been extinguished.

"I will never forget the memory of the late General Secretary Do Muoi, who once visited Binh Duong and wondered why the whole province made porcelain but could not produce a tea set to entertain guests, and had to buy it from abroad," Mr. Minh recalled and admitted: "At that time, the domestic bowls, cups and glasses were flooded with Chinese, French, and Japanese goods... Binh Duong province only had a few pottery kilns operating at a low level. Although the Vietnamese ceramic industry was born very early, it was sluggish because it could not compete with foreign goods."

So, despite his success in the world market, he decided to return to the domestic market, but things were not simple. Domestic consumers were too used to using foreign goods. To win them over, there had to be something different, special, and outstanding.

He began to travel abroad to explore and learn continuously. There was no country with a developed ceramic industry that he had not set foot in. The more difficult and challenging it was, the more it aroused the desire to conquer in businessman Ly Ngoc Minh. "Back then, the village had nearly 20 ceramic kilns, the scenery was poetic and beautiful, but poor. My mother was the owner of a ceramic production facility, but life was always short of money, only when she sold her products did she have money to buy rice. However, the difficulties helped to forge a spirit of perseverance" - Mr. Minh shared.

There are two major milestones in Minh Long 1's journey that come from this "persistence". The first is the success of the single-firing technology. Mr. Ly Ngoc Minh said that to burn at high temperatures, Western ceramic companies chose the double-firing technology. But he set a goal of only burning once, even though a Western company had tried for 7 years without success and had given up because the cost was too high. "It took me 12 years of research to succeed. In life, perseverance is the difference," Mr. Minh said.

Some products of Minh Long

Nguyen Nga

The story of Minh Long 1's "one-time firing" in ceramic production is a proud highlight of the domestic and world ceramic industry. The General Director of Germany's number one famous ceramic company, Rosenthal, in an interview with VTV affirmed: The world fires at a temperature of 1,380, but only Minh Long 1 fires once. In fact, for the ceramic industry, firing temperature is very important. Germany has the highest technology, firing up to 1,380 degrees Celsius but twice. Japan is up to 1,450 degrees, France is 1,350 degrees.... Switching to one-time firing technology has helped Minh Long 1 save maximum costs and improve quality. Thanks to that, Minh Long 1 ceramic products with thousands of designs have covered all market segments from hotels, households, used as gifts for heads of state in important events of Vietnam.

Second is the health pot set, Mr. Long spent 15 years researching production techniques, conducted hundreds of experiments, and traveled to countless quarries to find raw materials... before he succeeded.

Actually, Japanese ceramic pots have been made for more than 20 years, then China and Korea also made them. However, because of the nature of ceramic, when salty substances are added, the glaze cracks immediately, so after a while of use, this problem occurs.

"I researched and experimented with the production of ceramic pots using the thermal shock method from 750 degrees, up to 850... then took them out and soaked them in minus 5 degrees salt water. When I took them out, the pot was still intact and not broken. But I still didn't dare to release it. After two years of successful testing by my family, I announced it to the public. The clay pot is a dream of my mother's cooking pot that I spent all my heart, mind, and strength and 15 years to create. Not only that, health-preserving ceramic is also a gift of health. Whatever you do in life, think about human happiness and the greatest happiness in life is to have health" - he said.

Possessing superior technology, having different products, "defeating" foreign ceramic brands and setting the ambition to be in the top 10 largest enterprises in the international ceramic industry by 2030. But for businessman Ly Ngoc Minh: "A pearl thrown around is just like a stone, but if someone polishes it, the pearl will shine and have value. Minh Long 1 always wants to do better than what has been achieved and accepts hardships, surely heaven will not disappoint those who try."

The desire to put Vietnamese ceramics on the world map has always urged this man to work tirelessly. In 2022, he officially left the position of general director, transferring the captain's seat of the company to his son Ly Huy Sang, but in the position of chairman, he still works tirelessly. Every day, he starts at 5 am, exercises, and finishes breakfast at 7 am, he goes to work at the company. "I always tell my children that they must use all their human resources to know their destiny. If they are satisfied with what they have and have done, it is considered the end."

Therefore, after 53 years of establishment, Minh Long 1 products have been exported to many countries around the world, firmly established in the domestic market. In particular, Minh Long ceramics are always present on many national and international agendas, gifts for heads of state... However, Mr. Ly Ngoc Minh is still not satisfied when the large market of 1.4 billion people, China, is still "just approaching". He said, there are many difficulties in penetrating the cradle of world ceramics but "difficult does not mean impossible. So exporting goods to China needs to take longer. Only now do we see that we have enough strength to be able to do it".

Mr. Minh admitted that price is a challenging factor for exporters today when the world market is competing to use the most modern technology to produce competitive prices. A thin-screen TV used to cost 12,000 USD, but now it costs only a few hundred dollars to have something beautiful. The same goes for handmade products, which are much cheaper today than they were in the past. Therefore, according to Mr. Minh, when the world competes on price, Vietnamese goods must apply science and technology to compete with them. Each business has its own formula for success, but the general formula is to aim for the best, to be the best.

"I call the quintessential ceramic product that, because it is distilled from the two most quintessential and best elements. Besides, the more difficult it is, the more you have to focus on doing it with determination to the end with transparency and consistency. The world is flat, there is a lot of information, but learning and digging deep to understand a product and market is never out of fashion" - the white-haired man said, seeing no signs of rest in this businessman.

Thanhnien.vn

source

![[Photo] Panorama of the Opening Ceremony of the 43rd Nhan Dan Newspaper National Table Tennis Championship](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/19/5e22950340b941309280448198bcf1d9)

![[Photo] General Secretary To Lam attends the conference to review 10 years of implementing Directive No. 05 of the Politburo and evaluate the results of implementing Regulation No. 09 of the Central Public Security Party Committee.](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/19/2f44458c655a4403acd7929dbbfa5039)

![[Photo] Close-up of Tang Long Bridge, Thu Duc City after repairing rutting](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/19/086736d9d11f43198f5bd8d78df9bd41)

![[Photo] President Luong Cuong presents the 40-year Party membership badge to Chief of the Office of the President Le Khanh Hai](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/19/a22bc55dd7bf4a2ab7e3958d32282c15)

![[Photo] Prime Minister Pham Minh Chinh inspects the progress of the National Exhibition and Fair Center project](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/19/35189ac8807140d897ad2b7d2583fbae)

![[VIDEO] - Enhancing the value of Quang Nam OCOP products through trade connections](https://vphoto.vietnam.vn/thumb/402x226/vietnam/resource/IMAGE/2025/5/17/5be5b5fff1f14914986fad159097a677)

Comment (0)