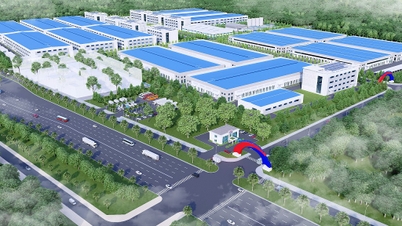

On November 13, the Aircraft Engine Corporation of China (AECC) announced the completion of the first test flight of a domestically developed and manufactured ultra-light miniature jet engine using advanced 3D printing technology.

This is the first time China has successfully tested the flight of a 3D-printed ultra-light miniature jet engine in the 160kg thrust class.

The engine is built using multidisciplinary topology optimization design and additive 3D printing techniques to achieve the design goals of ultra-light weight and high performance.

More than 75% of the total weight of the engine, including all rotating parts and major components, is manufactured using 3D printing technology. This manufacturing method significantly reduces the number of components, optimizes mass, and simplifies operations and maintenance (O&M) processes.

Flight test results showed that in 30 minutes, the engine reached a maximum altitude of 6,000m with a speed of Mach 0.75. The engine operated normally and stably.

This achievement follows the initial test flight conducted in July, in which the engine was able to operate stably and reliably in complex environments and at higher operating altitudes.

The success lays the foundation for future flights to reach higher altitudes and speeds. With the increasing application of design optimization and 3D printing technology in the field of aviation engines, the development cycle for future engines is expected to be shortened, accelerating China's progress in R&D and independent production of aviation power systems./.

Source: https://www.vietnamplus.vn/trung-quoc-thu-nghiem-thanh-cong-dong-co-phan-luc-sieu-nhe-in-3d-post1076927.vnp

![[Photo] General Secretary To Lam receives Vice President of Luxshare-ICT Group (China)](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/11/15/1763211137119_a1-bnd-7809-8939-jpg.webp)

![[Photo] Prime Minister Pham Minh Chinh meets with representatives of outstanding teachers](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/11/15/1763215934276_dsc-0578-jpg.webp)

Comment (0)