Updated date: 03/28/2024 09:36:12

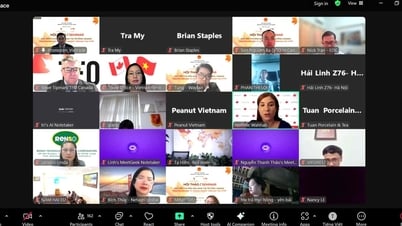

DTO - On the morning of March 28, the Department of Science and Technology organized a training course on "Awareness of Lean production methods and productivity improvement tools". Attending were representatives of leaders of economic /economic and infrastructure departments of districts and cities, along with production facilities and enterprises in the province.

Training class scene

According to experts, Lean is a systematic, continuous improvement method that focuses on creating more value for customers while eliminating waste in the production and service delivery processes of an organization, thereby helping to cut costs (which means increasing profits), optimize the use of resources, shorten production and service cycle times, and increase the ability to flexibly respond to the ever-changing and increasingly demanding requirements of customers.

In recent times, improving and promoting productivity has been one of the core issues for the economy. In the context of international integration and fierce competition, increasing productivity is the decisive factor for the competitiveness of the economy and each enterprise. For enterprises, increasing productivity creates greater profits and more investment opportunities to expand production. For workers, increasing productivity leads to higher wages and better working conditions. Increased labor productivity reduces product costs and helps improve product quality because it saves on wages per unit of product.

At the training course, experts shared information about the benefits and goals of the Lean production method; tools used to improve productivity, quality, benefits and application methods; practice of Lean production methods... Thereby, helping businesses gain more knowledge about the Lean production management model according to the Lean - 5S tool and eliminate challenges and waste in operations, be flexible and adapt to fluctuations due to the market; accumulate experience and capacity to improve efficiency and sustainable development. Along with that, businesses will gain many benefits when applying Lean such as: improving labor productivity, improving product or service quality, reducing administrative procedures, reducing pressure on employees and engaging employees more with their work.

JAPAN

Source

Comment (0)