|

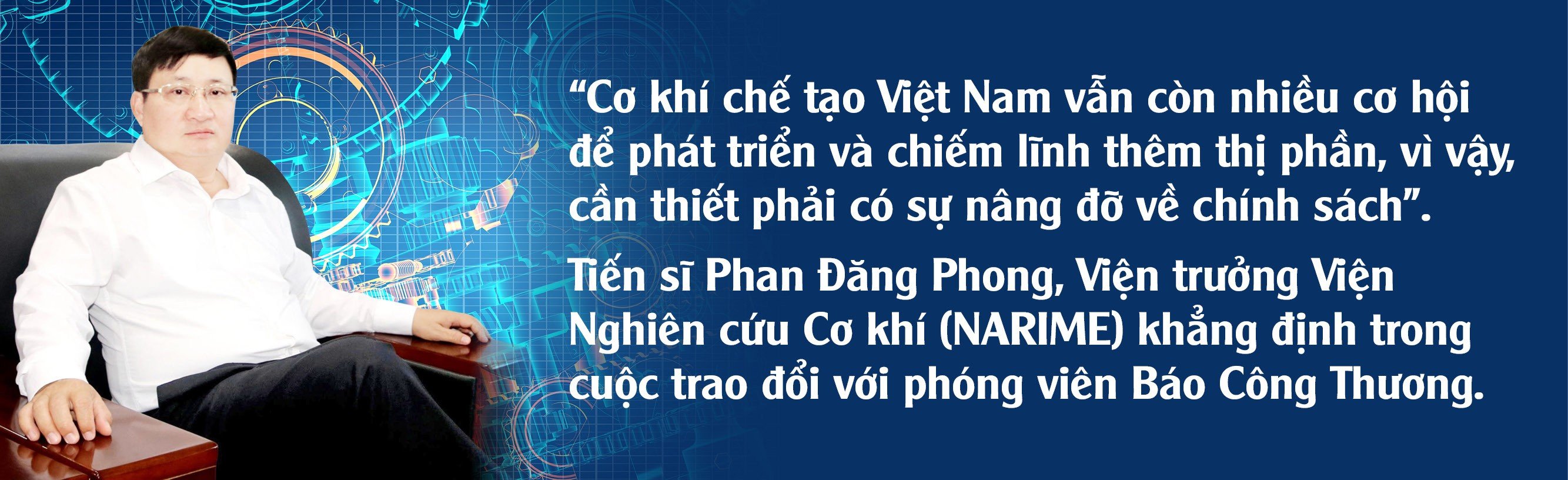

Dr. Phan Dang Phong: In recent times, the Vietnamese mechanical industry has developed with many positive changes, gradually mastering technology, expanding investment to improve product quality, increasing the localization rate and developing the market. Many products that were previously completely imported have now been gradually replaced by products manufactured by the domestic mechanical industry. Enterprises and research institutes have clearly demonstrated good capacity in a number of areas such as complete equipment lines in a number of industrial fields, molds of all kinds, mechanical components, electric cables, plastic components, technical rubber, etc. In particular, it has gradually participated in the production chain, supplying products to a number of large enterprises such as Toyota, Thaco , Thanh Cong, VinFast... creating momentum to promote the development of other industries and economies, thereby directly and indirectly creating jobs for millions of workers. According to some studies, domestically produced metal components have met about 15 - 40% of the demand for components for automobile production (depending on the vehicle type). For the railway sector, for locomotives, freight cars, and passenger cars, if the orders have suitable quantities, domestic units can participate in manufacturing with a localization rate of up to 60%. |

For example, currently, NARIME is the main supplier of equipment lines and welding fixtures, replacing foreign contractors for large domestic automobile factories. Specifically, NARIME has been designing, manufacturing, integrating, installing, and instructing the operation of equipment lines and welding fixtures for VinFast electric car models (such as VFe34; VF8; VF9; VF5; VF6; VF7; VF3) - jobs that were previously only performed by large foreign contractors (such as Thailand; Japan, Germany...), and no domestic unit could undertake. Or, we have also successfully implemented many automation projects, applying artificial intelligence (AI) to production processes in industrial factories such as: Project "Design, supply, installation and operation instructions for automatic loading and unloading robot system" for LIX Detergent Joint Stock Company; Project "SCADA system to monitor the entire detergent factory"; Project "Manufacture, supply and install automatic weighing system for Unilever detergent bagging"... The success of these projects has brought high economic efficiency to investors, saved human resources and contributed to modernizing the production process of existing lines. |

|

Dr. Phan Dang Phong: In the past time, with preferential support mechanisms and policies from the Government, the Ministry of Science and Technology, the Ministry of Industry and Trade in research activities, technology transfer, along with the efforts of the Institute of Mechanical Research in investing in capacity building and technology mastery, we have achieved some successes in scientific and technological research activities in the mechanical engineering - manufacturing industry for many fields of hydropower, thermal power, bauxite, cement, solar power... Many scientific and technological products implemented by NARIME have been granted exclusive patents and exclusive utility solution patents. For example, in the field of hydropower, the Institute has worked with domestic mechanical units to independently design and manufacture hydromechanical equipment for more than 29 medium and large hydropower projects in the country, including Son La hydropower project (2400 MW) and Lai Chau hydropower project (1200 MW), creating more jobs for the domestic mechanical industry with revenue from this sector bringing in about 8,000 billion VND, contributing to reducing product costs from 4.4 USD/1kg of product to 1.5 USD/1kg of product, contributing to generating electricity 3 years earlier for Son La hydropower plant and 1 year earlier for Lai Chau hydropower plant, bringing high economic efficiency to the projects. |

Or, in the field of thermal power, NARIME has also gradually mastered the technology of designing and manufacturing electrostatic dust collection systems, ash and slag disposal systems, coal loading and unloading systems, and fire prevention and fighting systems for the thermal power plants Vung Ang 1, Thai Binh 1, Song Hau 1, and Nghi Son 2. In particular, the project to research, design, manufacture, integrate and successfully put into operation the coal loading and unloading and transportation system for Song Hau 1 Thermal Power Plant with a localization rate of 50.6%, equivalent to technology equipment from G7 countries, is the first project implemented domestically, opening up a new development direction for the domestic mechanical engineering industry. In the field of construction materials production, the Institute has coordinated with Vietnam Machinery Installation Corporation to implement a large-scale science and technology project: "Research, design and manufacture key equipment for a synchronous production line of rotary kiln cement with a capacity of 2,500 tons of clinker/day, replacing imported products, implementing the localization process" with 3 topics (automatic bagging machine, large-capacity dust filter equipment and automatic control of factory equipment lines), successfully applied to the Song Thao rotary kiln cement project, achieving a localization rate of about 40% of the value... |

Dr. Phan Dang Phong: Studies show that the market potential of the mechanical engineering industry is huge. From now until 2030, the demand for the Vietnamese mechanical engineering market is about 310 billion USD, of which the demand for the automobile market alone is 120 billion USD. This industry also has many opportunities to benefit from production shifts, plus the ability to expand markets and attract investment when Vietnam participates in many free trade agreements. What domestic mechanical enterprises need most now is for the State to create markets, especially large-capacity markets such as urban railways, inter-regional railways, gas-fired power plants, offshore wind power projects, nuclear power, raw material production, etc. For example, if there are mechanisms and policies to prioritize reasonable development in the urban railway industry, the domestic localization rate can reach more than 79% - 83%, equivalent to 39.18 - 41.16 billion USD. This is a very large market, but foreign equipment suppliers are still dominating, and domestic mechanical enterprises participate very limitedly. In addition, Vietnam's choice to restart its nuclear power development plan also opens up opportunities for the mechanical engineering industry. The Government and the Ministry of Industry and Trade need to develop a research program for nuclear power equipment development, including a series of scientific and technological topics and projects. When each of these topics is successfully implemented, we will move towards completing the process of localizing nuclear power plants. |

I would also like to emphasize that we need to have policies to encourage the acquisition and mastery of technology in the first projects. With specific policies to increase the participation of Vietnamese enterprises in EPC complexes for nuclear power plants and railways in the coming time, it will be a good condition for us to be able to approach and learn from international experience from the beginning, and move towards mastering technology. In addition, some preferential mechanisms on finance, investment, tariffs... are very reasonable and good for mechanical enterprises. However, when applied in practice, there are still many problems, even slow and delayed, making it difficult for enterprises to apply. Some policies are still relatively strict, not really suitable, so it is very difficult for enterprises to access. On the other hand, it is necessary to evaluate and summarize the implementation process of the Strategy for the development of Vietnam's mechanical industry to 2025, with a vision to 2035, in order to review, adjust and supplement some contents of the strategy to suit the new situation, especially the need to adjust and supplement key mechanical products to suit the economic and social situation at home and abroad. Based on the adjusted Strategy for the development of the mechanical engineering industry, it is necessary to develop a comprehensive state program to support research and technology mastery in each specific field that is prioritized for development. Topics/projects registered and approved annually will closely follow the goals set out in this program. Obviously, Vietnamese mechanics still have many opportunities to develop and gain more market share, so it is necessary to have policy support from ministries, branches and the State in creating markets, linking product commercialization and improving technological capacity for enterprises. The issuance of policies to encourage the consumption of domestic mechanical products owned by Vietnamese research units is always expected by domestic research units. Along with that, research institutes and specialized mechanical units need to develop research programs, invest in scientific and technological potential to study and receive technology transfer to master the design and manufacture of entire equipment lines in these fields. Thank you! |

Quynh Nga Graphics: Hong Thinh |

Source: https://congthuong.vn/de-co-khi-che-tao-but-pha-can-don-bay-chinh-sach-388527.html

![[Photo] Scientific workshop "Building a socialist model associated with socialist people in Hai Phong city in the period of 2025-2030 and the following years"](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/21/5098e06c813243b1bf5670f9dc20ad0a)

![[Photo] Prime Minister Pham Minh Chinh receives Rabbi Yoav Ben Tzur, Israeli Minister of Labor](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/21/511bf6664512413ca5a275cbf3fb2f65)

![[Photo] Coming to Son La, let's "show off" with the Wallflowers](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/21/627a654c41fc4e1a95f3e1c353d0426d)

![[Photo] Prime Minister Pham Minh Chinh receives the President of Asia-Pacific region of PowerChina Group](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/21/0f4f3c2f997b4fdaa44b60aaac103d91)

Comment (0)