Some common issues of ecological innovation in the textile industry

Eco-innovation is the process of creating new changes in products, processes, technologies and business models to minimize environmental impacts and optimize resource use. Unlike traditional innovation that focuses only on economic efficiency, eco-innovation aims at the dual goal of creating economic value and contributing to environmental protection. In sustainable economic development, eco-innovation plays an endogenous driving force, helping to transform from a linear economic model to a circular economy. This process not only addresses environmental challenges but also creates new competitive advantages, improves resource efficiency, and promotes high-quality economic growth.

For the textile industry, ecological innovation is reflected in three aspects, including: Innovation in production technology (saving energy, water, reducing chemicals); product innovation (recycled materials, environmentally friendly); business model innovation (sustainable supply chain, circular economy). This combination helps the textile industry meet international environmental requirements, improve competitiveness and contribute to sustainable economic growth.

According to the Organization for Economic Cooperation and Development (OECD), eco-innovation is “the process of developing new products, processes, services, technologies and business models that reduce negative environmental impacts, optimize resource use and create new value for businesses and society” (1) . In the textile industry, eco-innovation brings dual environmental and economic benefits. Clean technology investment projects in the textile industry have an average payback period of 1-3 years, with an internal rate of return much higher than conventional investment projects (2) . Research shows that textile companies that adopt sustainable business models are significantly more likely to increase their stock value than their competitors in the industry (3) .

In the context of globalization and deep international integration, the world textile and garment industry is facing an urgent need to transform its development model towards sustainability. The textile and garment industry has a significant impact on global greenhouse gas emissions, consumes huge amounts of water and discharges large amounts of industrial wastewater (4) . A report by the Ellen MacArthur Foundation indicates that a significant proportion of fabric produced is wasted during the cutting and sewing process (5) . According to Fashion Revolution, the majority of garments end up in landfills every year (6) . Important export markets have introduced many new regulations on environmental standards. The European Union (EU) implemented the Sustainable Textile Strategy 2022, from 2025 applying the Carbon Border Adjustment Mechanism (7) . The United States enacted the Pollution Prevention Priorities Act and the Clean Water Act. Japan applies the Law on Promotion of Green Procurement, South Korea implements the Carbon Labeling Program (8) . These pressures require the textile industry to transform from a linear economic model to a sustainable circular economic model (9) .

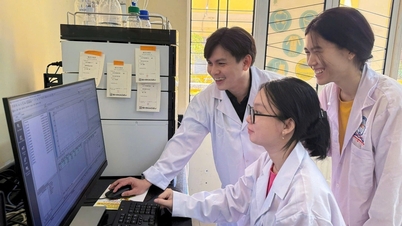

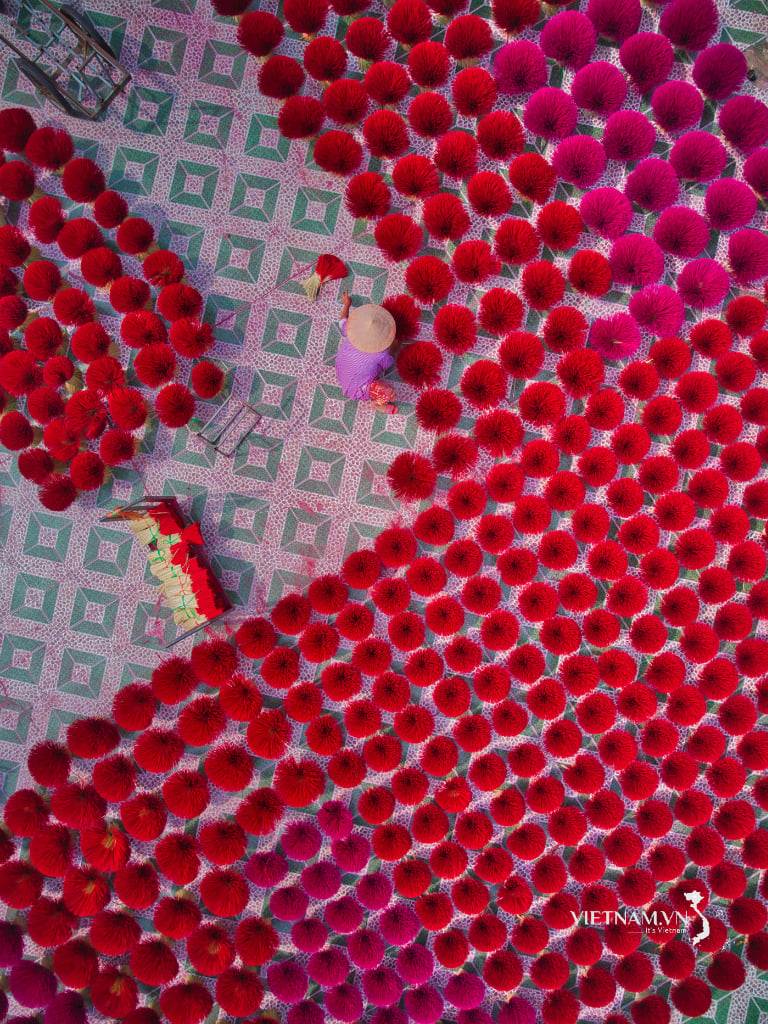

The textile and garment industry is one of the key export industries and creates jobs for about 2.5 million workers in Vietnam_Source: nhiepanhdoisong.vn

Recognizing the importance of sustainable development, our Party and State have put forward many strategic policies. The documents of the 13th National Party Congress set out the requirement for rapid and sustainable development based mainly on science and technology, innovation and digital transformation. Resolution No. 57-NQ/TW, dated December 22, 2024, of the Politburo , on "Breakthrough in science, technology, innovation and national digital transformation" affirms that the development of science, technology, innovation and national digital transformation is the top important breakthrough. In Vietnam, the textile and garment industry is one of the key export industries, with a turnover of over 40 billion USD per year, contributing about 16% of total export turnover and creating jobs for about 2.5 million workers (10) . However, according to a report by the Ministry of Natural Resources and Environment, textile and dyeing production facilities discharge large amounts of wastewater with high levels of pollutants and consume a significant proportion of electricity in the industrial sector with low energy efficiency (11) .

In the context of deep international integration, proactively applying ecological innovation not only helps the Vietnamese textile and garment industry respond to environmental challenges but also creates new competitive advantages, enhances its position in the global value chain, and contributes to the goal of sustainable economic growth. According to forecasts, if Vietnamese textile and garment enterprises apply ecological innovation solutions, by 2030, the industry can significantly reduce carbon emissions, save energy and water costs, increase export value and create many new green jobs (12) . International experience shows that Vietnam needs to have a comprehensive strategy on ecological innovation for the textile and garment industry, in which building a suitable legal framework and economic tools; promoting public-private partnership in research and development; improving capacity for enterprises, especially small and medium enterprises; and strengthening international cooperation to access advanced technology (13) are necessary. At the same time, take advantage of opportunities from free trade agreements to attract investment, transfer technology and participate in the global green value chain.

Ecological innovation in Vietnam's textile industry in recent times

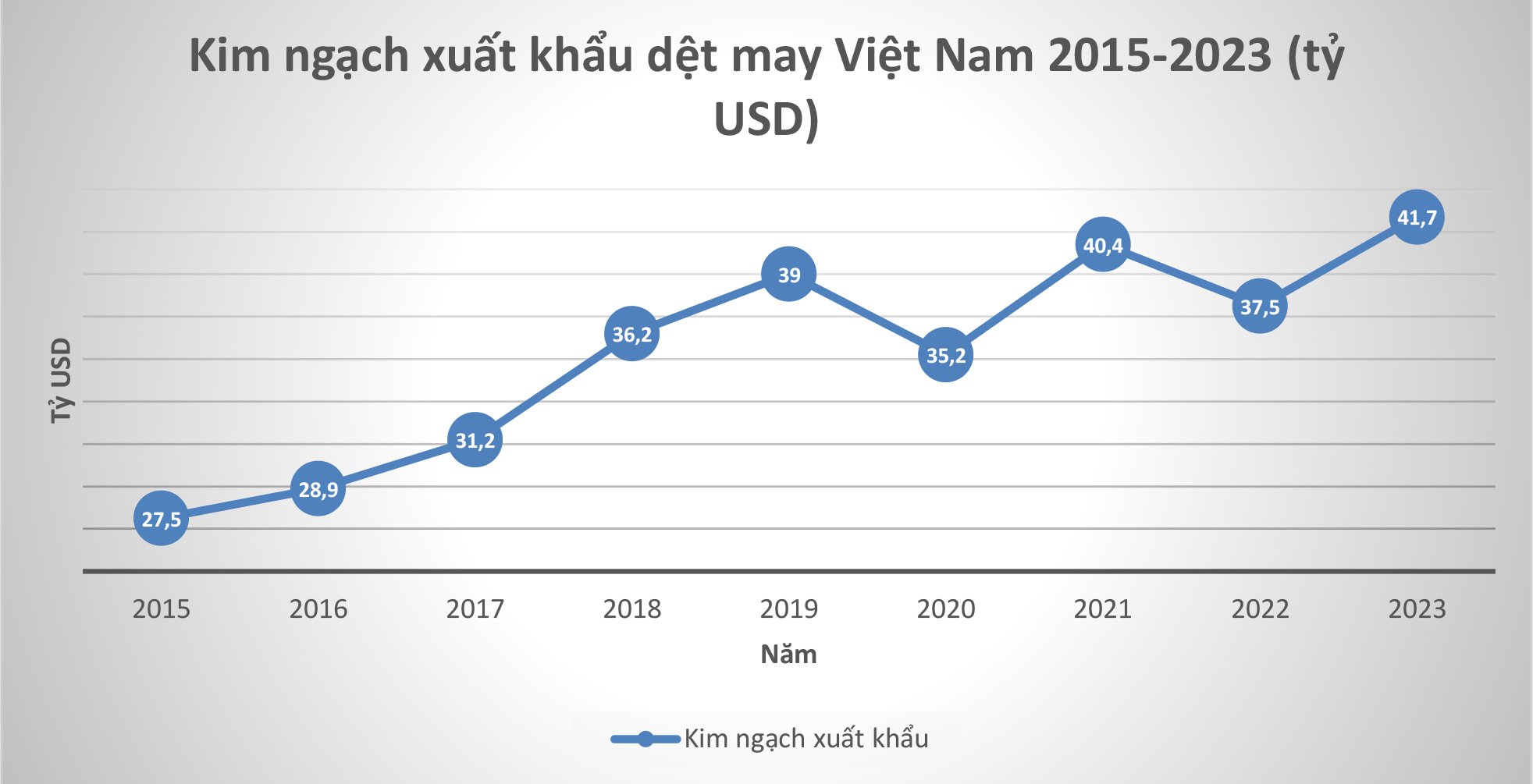

Vietnam's textile and garment industry has made remarkable progress over the past decade, affirming its important position in the economy. According to data from the Vietnam Textile and Apparel Association (VITAS), in 2024, textile and garment export turnover reached 44 billion USD, making Vietnam one of the three largest textile and garment exporting countries in the world. The textile and garment industry has created jobs for about 2.5 million workers, contributing about 12% to the total value of national industrial production. In particular, the textile and garment industry has gradually shifted from a competitive advantage based on low labor costs to a model based on productivity, high added value and sustainable development. The value-added ratio in exported textile and garment products increased from 36% (in 2015) to 48% (in 2023). This development is reflected in the steady growth in export turnover in the period 2015 - 2023 in Chart 1.

Chart 1. Vietnam's textile and garment export turnover in the period 2015-2023 (14)

Source: Compiled from data of Vietnam Textile and Apparel Association (VITAS) and General Statistics Office (2015-2023)

The trend of eco-innovation in Vietnam's textile and garment industry began to take shape clearly in 2015, when Vietnam joined new-generation free trade agreements such as CPTPP, EVFTA and RCEP. According to a survey by VITAS in 2023, 65% of enterprises have implemented at least one eco-innovation initiative, a significant increase compared to 2018. However, the level of implementation is uneven, with 85% of large enterprises having eco-innovation initiatives, while small and medium enterprises only reached 42%.

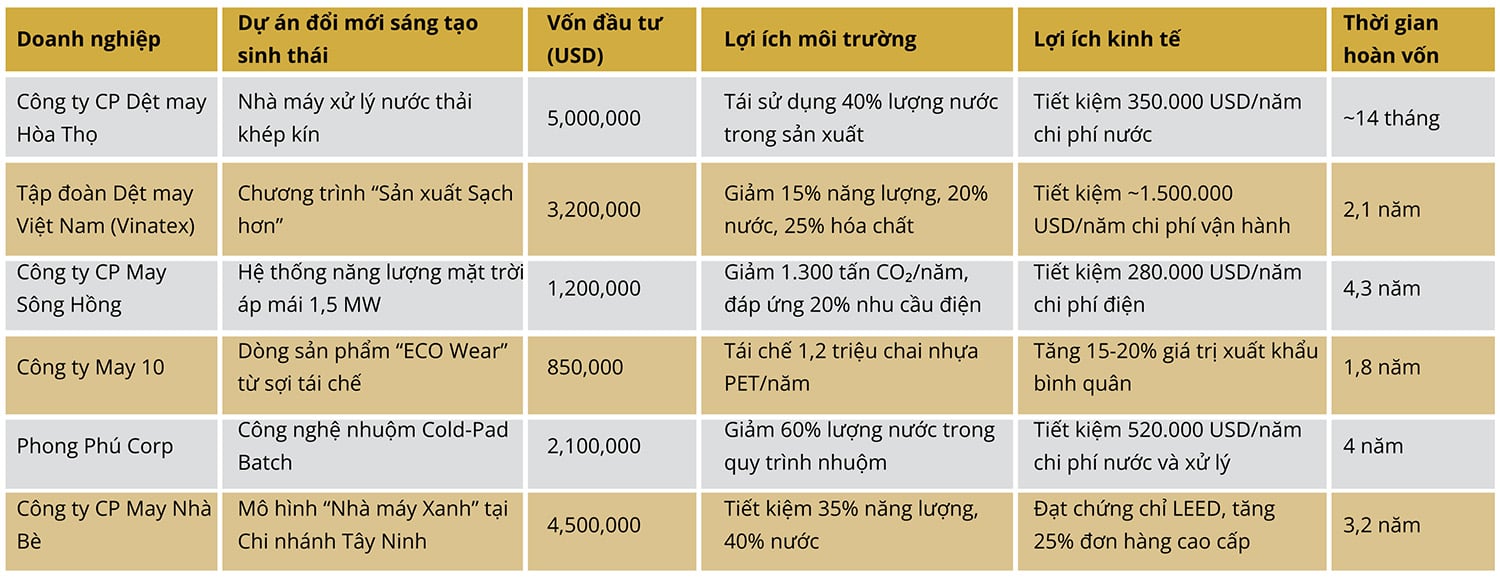

Regarding innovation in the production process, many enterprises have invested in energy and water saving technology. Hoa Tho Textile Joint Stock Company has built a closed wastewater treatment plant with an investment capital of 5 million USD, helping to reuse 40% of water in the production process, saving 350,000 USD/year in water costs. In the field of product innovation, the trend of developing environmentally friendly product lines is of interest. May 10 Company has developed the product line "Eco-Wear" using recycled fibers from PET plastic bottles and organic cotton fabric, helping to recycle 1.2 million PET plastic bottles/year and increase the average export value by 15-20%. Phong Phu Corp has applied Cold-Pad Batch water-saving dyeing technology, helping to reduce 60% of water in the dyeing process. The figures in Table 1 show clear economic and environmental benefits with reasonable payback periods ranging from 1.8 to 4.3 years, demonstrating the feasibility of investing in green technology.

Table 1: Economic efficiency of eco-innovation projects in Vietnamese textile and garment enterprises

Source: Compiled from VITAS reports and 2023 business survey data

Innovation in business models and supply chains is being actively implemented. Some large enterprises such as Vinatex, TNG, Viet Tien have begun to apply the circular economy model by recovering waste from the fabric cutting process for recycling. Nha Be Garment Joint Stock Company has developed a “Green Factory” model at its Tay Ninh branch, applying LEED standards with a smart energy management system, helping to save 35% of energy, 40% of water and increase 25% of high-end orders. A green supply chain management system is being built, with many enterprises applying international standards in supplier selection.

In terms of economic impact, eco-innovation has significantly contributed to the growth of the industry. Research by the Institute for Trade Strategy Research shows that textile and garment enterprises applying eco-innovation have an average revenue growth rate 15-20% higher than traditional enterprises. Labor productivity at these enterprises reaches 6,300 USD/person/year compared to the industry average of 5,500 USD/person/year. Regarding national GDP growth, textile and garment enterprises applying eco-innovation have created higher added value than traditional production methods. A report by the Ministry of Planning and Investment estimates that green production in the textile and garment industry alone will contribute about 0.3% to GDP growth in 2023 (15) . Regarding exports, green-certified textile products are being sold at 10-15% higher prices than conventional products, helping to increase export turnover and improve the trade balance (16) .

Despite the positive results, the process of ecological innovation in the Vietnamese textile and garment industry still faces many challenges. Firstly , financial barriers with very high initial investment costs for green technology, averaging from 1 to 3 million USD for a medium-sized factory (17) . VITAS survey shows that 70% of small and medium-sized enterprises have difficulty accessing capital for ecological innovation projects, while financial support mechanisms from the government are still limited. Secondly , the problem of shortage of high-quality human resources with 60% of enterprises lacking experts in the field of green production and environmental management. The current training system has not kept up with actual needs, many engineers lack knowledge of international standards such as GOTS, OEKO-TEX, GRS (18) . Third , the legal framework, mechanisms and policies are not yet synchronized, administrative procedures are complicated, and coordination between ministries and branches is not tight, leading to overlapping in implementation guidelines. Fourth, the industry's research and development (R&D) capacity is still weak, with average R&D costs reaching only 0.5 - 0.8% of revenue, much lower than the 2 - 3% of the world's leading enterprises. The connection between enterprises and universities and research institutes is still loose (19) .

Overall, eco-innovation in the Vietnamese textile and garment industry is at an important stage of transformation, with initial positive results, but many challenges need to be overcome to fully exploit its potential. According to VITAS forecast, by 2030, if 80% of Vietnamese textile and garment enterprises apply eco-innovation, the industry can contribute an additional 0.5% to annual GDP growth, create 200,000 more green jobs and reduce carbon emissions by 30%. These achievements will help Vietnam improve its position in the global textile and garment value chain and promote the transition to a green and sustainable economy.

Garment workers at 29-3 Textile Joint Stock Company_Photo: VNA

Solutions to promote ecological innovation in Vietnam's textile and garment industry in the coming time

To promote ecological innovation in the Vietnamese textile and garment industry, a system of synchronous solutions is required, from macro policies to specific support measures for businesses. Based on the current situation and challenges, it is necessary to focus on effectively implementing the following main solutions:

Firstly , perfecting the mechanism and policies to encourage ecological innovation. Building a synchronous incentive policy system for textile and garment enterprises to invest in green technology, including corporate income tax exemption and reduction in the first 3-5 years of implementation, rapid depreciation of fixed assets serving ecological innovation, and interest rate support for loans to invest in energy-saving technology. According to international experience, the tax incentive level should reach at least 30-40% of the investment value to create a strong enough motivation for enterprises (20) .

Second , build a system of standards and evaluate the effectiveness of ecological innovation. It is necessary to build a set of criteria for evaluating sustainable textile and garment enterprises (Vietnam Sustainable Textile Index - VSTI), as a basis for ranking and motivating enterprises to promote ecological innovation. This set of criteria includes main groups of indicators, namely: Efficiency of resource use; waste and emission management; chemical safety; technological innovation and R&D capacity; social responsibility. It is necessary to issue Vietnamese standards (TCVN) on green textile products, clean production processes and guidelines for applying circular economy in the textile and garment industry (21) .

Third , strengthen the capacity for research, development and transfer of green technology. In the spirit of Resolution No. 57-NQ/TW of the Politburo, it is necessary to establish a Center for Research and Transfer of Sustainable Textile Technology, with an initial investment scale of about 30 million USD (22) . The Center will focus on 5 priority areas including: Energy and water saving technology; development of environmentally friendly materials; waste treatment and recycling technology; digital technology in textiles; sustainable design. The Ministry of Science and Technology needs to prioritize allocating at least 5% of funding from national science and technology programs to research topics on green technology in textiles.

Fourth , developing human resources for ecological innovation. It is necessary to reform the textile and garment training program at vocational and university education institutions, adding subjects on green technology, circular economy, sustainable supply chain management and ecological design. According to VITAS's assessment, the textile and garment industry needs about 8,000 engineers and 20,000 technical workers in the field of green technology by 2030 (23) . It is necessary to build a pilot training program "Green Engineers in the Textile and Garment Industry" according to the "dual training" model, combining theory at school and practice at enterprises.

Fifth , strengthen international cooperation in technology and experience transfer. Promote the formation of international cooperation projects on sustainable development in the textile and garment industry, with the goal of attracting at least 200 million USD in ODA and FDI capital into the green technology sector in the next 5 years. Priority should be given to cooperation with partners from the EU, Japan, Korea, etc., countries with experience and advanced technology in this field.

In the development orientation for the period 2025 - 2030, the Vietnamese textile and garment industry needs to strive to have the majority of enterprises applying ecological innovation solutions by 2030, significantly reducing water and energy consumption, increasing the rate of using recycled materials and increasing the rate of exported products meeting international green standards. By promoting ecological innovation, the textile and garment industry will not only improve its competitiveness in the international market but also actively contribute to the process of transforming the country's growth model towards sustainability, efficiency and inclusiveness./.

------------------------

(1) OECD: Eco-innovation in the textile industry: Policies and best practices, OECD Publishing , Paris, 2020

(2), (18) World Resources Institute: The True Cost of Sustainable Fashion, WRI Report , Washington, 2021

(3), (17) Boston Consulting Group: The Business Case for Sustainable Fashion , Boston, USA, 2022

(4), (23) UNEP: Global Environment Outlook: The Textile Industry and Sustainability, United Nations Environment Program , Nairobi, 2022

(5) Ellen MacArthur Foundation: A New Textiles Economy: Redesigning Fashion's Future, Isle of Wight , UK, 2021

(6) Fashion Revolution: The Fashion Transparency Index 2023 , London, 2023

(7) European Union: EU Strategy for Sustainable Textiles, European Commission , Brussels, 2022

(8), (16), (21) Tran Thi Mai, Le Quang Thang: "Solutions for sustainable development of Vietnam's textile and garment industry in the context of climate change", Industry and Trade Magazine , No. 8 (2022), pp. 112 - 120

(9), (20) Nguyen Thi Lan Huong: "Circular economy in Vietnam's textile and garment industry - Current situation and solutions", Journal of Economics and Development , No. 6 (2022), pp. 25 - 32

(10) Ministry of Industry and Trade: Report on the development of Vietnam's textile and garment industry in 2023 , Hanoi

(11) Ministry of Natural Resources and Environment: Report on the environmental status of Vietnam's textile and garment industry , Hanoi, 2022

(12), (19), (22) Institute for Trade Strategy Research: Research report on the economic impact of ecological innovation in the Vietnamese textile and garment industry , Hanoi, 2023

(13) Pham Van Tuan: "Eco-innovation: The driving force for sustainable development of Vietnamese enterprises in the context of integration", Foreign Economic Journal , No. 125 (2021), pp. 48 - 57

(14) See: General Statistics Office: Statistical Yearbook 2023, Statistical Publishing House, Hanoi, 2023

(15) See: Ministry of Planning and Investment: Report on economic impact assessment of green manufacturing industries , Hanoi, 2023

Source: https://tapchicongsan.org.vn/web/guest/kinh-te/-/2018/1094102/doi-moi-sang-tao-sinh-thai-trong-nganh-det-may-viet-nam---dong-luc-cho-tang-truong-kinh-te-ben-vung.aspx

![[Photo] Hue: Inside the kitchen that donates thousands of meals a day to people in flooded areas](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/10/29/1761738508516_bepcomhue-jpg.webp)

![[Photo] Prime Minister Pham Minh Chinh chaired a meeting to discuss solutions to overcome the consequences of floods in the central provinces.](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/10/29/1761716305524_dsc-7735-jpg.webp)

![[Photo] Prime Minister Pham Minh Chinh chaired a meeting to evaluate the operation of the two-level local government model.](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/10/29/1761751710674_dsc-7999-jpg.webp)

![[Photo] Human love in the flood in Hue](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/10/29/1761740905727_4125427122470875256-2-jpg.webp)

![[Live] Concert Ha Long 2025: "Heritage Spirit - Brightening the Future"](https://vphoto.vietnam.vn/thumb/402x226/vietnam/resource/IMAGE/2025/10/29/1761743605124_g-anh-sang-am-thanh-hoanh-trang-cua-chuong-trinh-mang-den-trai-nghiem-dang-nho-cho-du-khach-22450328-17617424836781829598445-93-0-733-1024-crop-1761742492749383512980.jpeg)

Comment (0)