PASSION FOR CREATIVITY

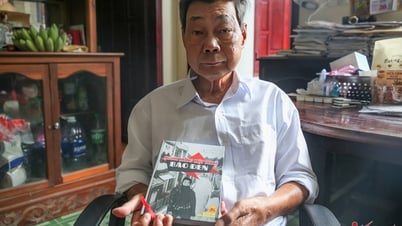

Mr. Thien comes from a family with a tradition of working in mechanics and manufacturing agricultural machinery. Among them, the combine harvester branded “Tu Sang” is one of the products that has made a name for itself and is known nationwide.

|

| Engineer Thien (right cover) constantly researches and creates many useful products to serve agricultural production. |

After graduating from high school, Mr. Thien entered Ho Chi Minh City University of Technology, majoring in Mechanical Engineering. After graduating, he returned to his hometown to follow his father's footsteps and develop the mechanical workshop into Tu Sang LLC, specializing in converting and manufacturing agricultural machinery.

With the knowledge accumulated from school, combined with his father's experience and the reality of "sticking" to the fields, engineer Thien and his colleagues have constantly researched, invented, and improved many types of useful mechanical machines for rice cultivation across the country.

One of the highlights is the research and improvement of the traditional combine harvester. It is a machine running on rubber tracks to increase the ability to resist sinking when moving on the field. The machine can harvest fallen rice, even in the rain. After threshing, the clean rice is put into the storage tank without being affected and depending on whether the rice is wet or not.

According to engineer Thien, the mechanical profession, especially the manufacturing of agricultural machinery, requires a lot of effort and intelligence to research and create products suitable for the farming conditions of each locality. Therefore, in the creative process, he not only applies knowledge but also has to directly follow the reality in the fields, work closely with farmers, listen to their thoughts and aspirations to create suitable products.

After many years of operation, from the foundations achieved, the company continues to research to produce increasingly modern mechanical equipment and machinery to serve farmers. First of all, it reduces labor in the face of the current shortage of rural labor. On the other hand, when applying new equipment, it will increase profits for farmers.

From 2018 to now, he has invented many new machines such as: Seeding machine, straw rolling machine, fertilizer mixer... In particular, the self-propelled straw rolling machine he invented can collect straw on an area of 5 hectares/day, replacing about 50 manual workers.

This is a device that is very popular with farmers. In recent years, farmers have been increasing the use of straw for livestock and crop production. Up to now, the company has produced more than 500 straw rolling machines. Other types of machines such as sowing, mixing fertilizer, digging and burying fertilizer... have also been produced in hundreds of units, serving all regions of the country.

Sharing about his journey of nearly 30 years working in the mechanical engineering profession, engineer Thien confided: “I see that the need for mechanization is increasing, there must be many types of machines to help production become more efficient, bringing economic efficiency to farmers - from tilling the land, harvesting, straw treatment to sowing... Many times I was very worried because I could not solve the problem. But when I did, I was very excited, both helping the company develop and meeting the practical needs of the people".

CONTINUOUS IMPROVEMENT

In fact, most of the machines that Engineer Thien has improved and invented are suitable for practical agricultural production, saving costs for farmers. Among them, the combine harvester has won many prestigious awards.

|

| The combined seeding machine and fertilizer burying machine invented by Tu Sang Company Limited participates in the Project of Sustainable Development of One Million Hectares of High-Quality and Low-Emission Rice Cultivation. |

Accordingly, the company won the first prize in the Mekong Delta Combine Harvester Competition and the Northern Provinces Combine Harvester Competition. The company's products have been trusted by customers. This is the company's motivation for development.

Engineer Thien said that the current trend in our country is to focus on implementing the Project "Sustainable development of one million hectares of high-quality and low-emission rice cultivation associated with green growth in the Mekong Delta region.

This is very important in that it will improve the quality of our rice products, reduce costs and increase profits for farmers. At the same time, it will reduce greenhouse gas emissions to contribute to environmental protection.

There are many tasks to be done in this project, including mechanization. Accordingly, after a period of research, the company has developed new products such as a seeding machine combined with fertilizer burying. The company has demonstrated in many models and many places for replication.

The results achieved when using a seeding machine combined with burying fertilizer are reducing the amount of seeds sown by about 50%, reducing fertilizer by 10% - 20%; better fertilizer efficiency; reducing pesticides by 1 - 3 times; productivity can increase by up to 15%. Thereby, helping to reduce costs in rice production, increasing profits.

Mr. Chau Minh Hai, Director of HK Trading Company Limited (My Phong Ward, Dong Thap Province) commented: “Mr. Thien’s company has supported our company to implement the production value chain by using a row seeding machine combined with burying fertilizer to build a standard model to reduce emissions. Farmers were a bit confused at first, but the results were very positive - reducing the amount of seeds, saving costs and achieving high economic efficiency. The machine works very well.”

Currently, engineer Thien and his colleagues at the company are continuing to research and improve products to meet the increasing needs of farmers, especially in the Project for Sustainable Development of One Million Hectares of High-Quality and Low-Emission Rice Cultivation.

Engineer Thien added: “We always research from machinery, equipment to field experiments in many places. This is to ensure that the machine works well in many different terrains. The ultimate goal is the highest economic efficiency. We must always improve to make the product more perfect.”

T. DAT

Source: https://baoapbac.vn/kinh-te/202507/ky-su-nguyen-hong-thien-voi-nhieu-san-pham-thuc-day-co-gioi-hoa-nong-nghiep-1047466/

![[Photo] National Assembly Chairman attends the seminar "Building and operating an international financial center and recommendations for Vietnam"](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/7/28/76393436936e457db31ec84433289f72)

Comment (0)