TIEN GIANG Due to being in trial operation, the factory only operates at about 60% capacity, recovering 30 - 50% (30 tons) of raw materials per day.

TIEN GIANG Due to being in trial operation, the factory only operates at about 60% capacity, recovering 30 - 50% (30 tons) of raw materials per day.

The large amount of durian husks generated from export peeling businesses needs to be treated to avoid environmental pollution. Photo: Minh Dam .

Tien Giang is the locality with the largest fruit garden in the Mekong Delta, with an area of about 84 thousand hectares and an output of about 1.8 million tons. In addition to fresh consumption, many businesses also process canned, frozen, dried fruits for export, bringing high added value.

Some typical fruit processing factories in Tien Giang province include Hung Phat, Long Uyen, Cat Tuong, Thabico, Tien Giang Vegetables and Fruits... In particular, dozens of enterprises, establishments and cooperatives peel durian pulp for export in the form of frozen durian pulp, generating a large amount of durian peel that needs to be processed. Currently, the rate of by-product waste in mango processing is about 40%, and for durian it is about 50%. According to estimates, the amount of by-product waste from fruit processing activities (such as peels and seeds) is about 500 tons per day. However, there is still no unit using this by-product waste to reuse for the agricultural sector.

In order to meet the need for processing waste by-products from fruit processing activities to avoid environmental pollution, DTH Green Environment Company Limited (My Phuoc town, Tan Phuoc district, Tien Giang province) has researched and developed processes, technologies and equipment to turn them into useful products that can be used as raw materials to produce organic fertilizers that are very good for agriculture. This is the first enterprise in Tien Giang province to put into operation this waste by-product processing line.

Putting fruit peels and seeds into the processing line. Photo: Minh Dam .

Mr. Duong Hoang Hieu, Director of DTH Green Environment Company Limited shared: "We came up with the idea of incorporating a process of turning organic waste such as mango peels, durian peels... into organic fertilizers that are useful for agriculture. The implementation process will be divided into two phases. The first phase will invest in a factory to process fruit peels and seeds into raw materials so that they can no longer pollute the environment.

Phase 2 will continue to research and turn the finished product in phase 1 into a mixed material with some other ingredients to become organic fertilizer specifically for each specific type of crop such as durian, jackfruit, rice, vegetables, etc.

Currently, this factory is in the first phase of trial operation. The factory has an investment of over 15 billion VND on an area of over 1 hectare, with a modern machinery and equipment system, with a designed capacity to process about 100 tons of fruit peels and seeds per day. However, because it is in the trial phase, the factory is only operating at about 60% capacity, recovering 30 - 50% (30 tons) of raw materials per day.

Spraying microorganisms before bringing to the greenhouse for composting. Photo: Minh Dam.

After being received at the waste source, the waste will be transported to the factory's reception area. Here, they will be taken to the microbiological treatment area and continue to go through the stages of grinding, water separation, and drying. After drying, they will continue to be brought to the greenhouse for microbiological incubation for about 7 days. Finally, they will be crushed, becoming a porous material, very rich in nutrients and safe for the environment, which can be used to fertilize plants, but need to be mixed with additional ingredients to suit each type of plant.

In phase 1, the factory processed the peels of fruits such as mango, durian, dragon fruit... contributing to helping businesses and fruit processing facilities in Tien Giang province solve the immediate problem of collecting and treating waste in accordance with regulations, without causing environmental pollution.

Mr. Duong Hoang Hieu, Director of DTH Green Environment Co., Ltd. added: “In the first phase, we will focus on processing organic waste and fruit peels to no longer pollute the environment. After completing the second phase, we can commercialize it to serve the agricultural sector. Specifically, we expect to implement the second phase in the middle of next year.”

Mr. Duong Hoang Hieu, Director of DTH Green Environment Company Limited, introduces the finished product of phase 1 to visitors. Photo: Minh Dam.

Talking about putting into operation a factory to process fruit peels and seeds to produce organic fertilizers for agriculture, Dr. Nguyen Thi Ngoc Truc, Head of the Department of Agronomy (Southern Fruit Institute) said that organic microbial fertilizers made from fruit peels and seeds are very nutritious, especially mango peels and durian peels.

According to Dr. Truc, in the process of intensive fruit cultivation, farmers add fertilizer to make the fruit sweet and fat. When nutrients are fed to the fruit, they are accumulated in the flesh, peel and even the seeds. Therefore, using peel and seeds to compost organic fertilizer will return them to the soil, which is very necessary. However, the problem here is that the technology process of processing and composting fertilizer must ensure that it is free of pathogens so that it can be fertilized for plants with high efficiency.

According to Mr. Trinh Van Sy, owner of a durian business in Ngu Hiep commune (Cai Lay district, Tien Giang), a fruit peel processing factory, including durian peels, is very necessary to help solve the problem of fruit peels that have been stagnant for many years, contributing to helping businesses process durian for export and thoroughly handling the problem of widespread durian peel disposal that causes environmental pollution.

Source: https://nongsanviet.nongnghiep.vn/nha-may-bien-vo-trai-cay-thanh-phan-bon-huu-co-dau-tien-o-tien-giang-d410058.html

![[Photo] Nhan Dan Newspaper displays and solicits comments on the Draft Documents of the 14th National Party Congress](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/10/26/1761470328996_ndo_br_bao-long-171-8916-jpg.webp)

![[Photo] Enjoy the Liuyang Fireworks Festival in Hunan, China](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/10/26/1761463428882_ndo_br_02-1-my-1-jpg.webp)

![[Photo] General Secretary To Lam received the delegation attending the international conference on Vietnam studies](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/10/26/1761456527874_a1-bnd-5260-7947-jpg.webp)

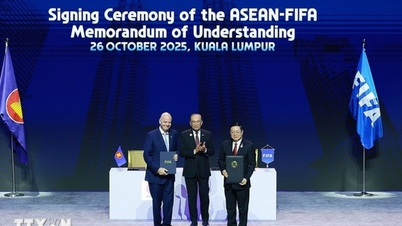

![[Photo] Prime Minister Pham Minh Chinh attends the opening of the 47th ASEAN Summit](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/10/26/1761452925332_c2a-jpg.webp)

Comment (0)