When talking about Phan Thiet, it is impossible not to mention fish sauce - a product that has been famous for a long time in this land. However, few people know that what contributes to making the flavor of fish sauce "fly high and far" is thanks to the tin - the main tool for storing fish sauce before 1975.

1. Origin of the name

The fish sauce making profession in Binh Thuan was born and developed quite early. From the time of the Nguyen Lords to the Nguyen Dynasty, fish sauce was one of the products subject to special tax. In the 18th-19th centuries, through some historical documents such as: Phu Bien Tap Luc, Kham Dinh Dai Nam Hoi Dien Su Le, Dai Nam Thuc Luc, Dai Nam Nhat Thong Chi, the containers for fish sauce to pay tax were jars, jars or urns. Later (perhaps from the French colonial period), the name "Tin" began to appear among the people, gradually becoming familiar and popular.

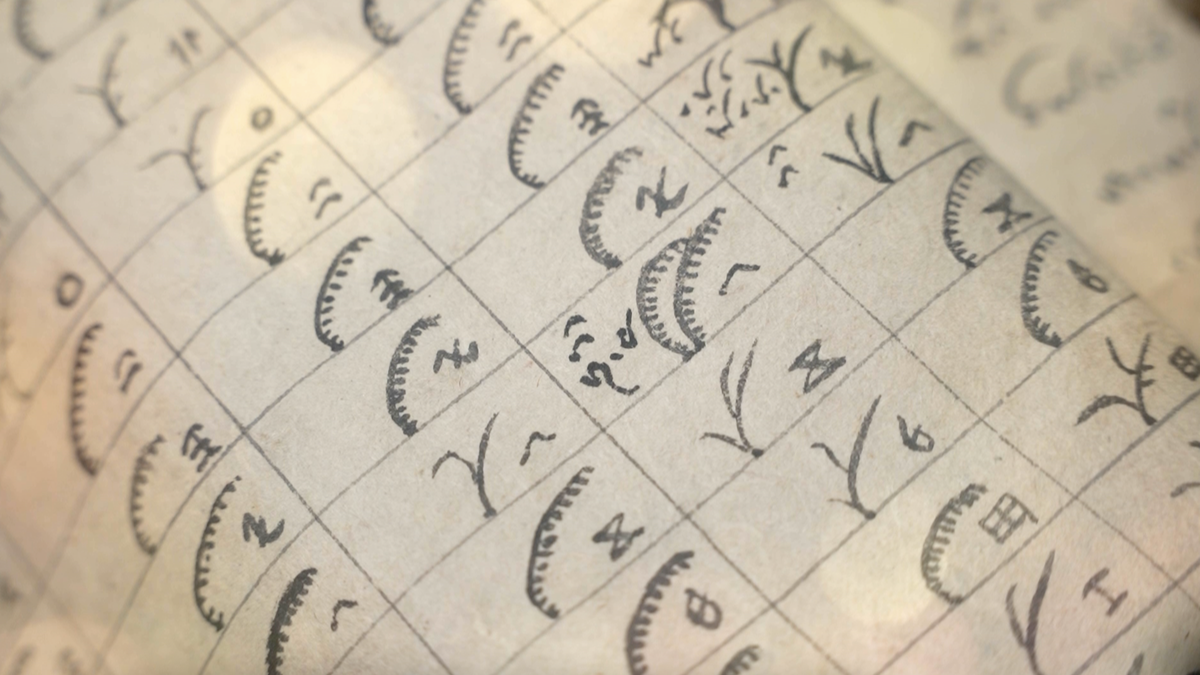

The names tĩn and tĩn are both correct, both refer to a type of small, low jar, round and pointed in the middle like a rice cake. These are names that the ancients borrowed from Chinese characters to transcribe into Vietnamese. According to author Vũ Văn Kính (Great Dictionary of Nom Characters, 2005), tĩn comes from the word 井 (read in Sino-Vietnamese as Tĩnh); and tĩn comes from the two words Kim/金 and Tĩnh/省 combined (according to the harmonic sound).

2. Time of birth and production location

The tin making profession in Binh Thuan began in 1927, in what we now call Lo Tin hamlet. This place is located in the southwest of Phan Thiet city, between kilometer 3 and 4 on Tran Quy Cap street in Duc Long ward - bordering Tien Loi commune.

By the 1960s, in this area (then called Phu Phong B hamlet, Phu Lam commune, Ham Thuan district) there were a total of 5 tin kilns, all privately owned and branded: Minh Thanh, Cong Minh, My Loi, Hiep Nghia and Hiep Thanh.

3. Production capacity

According to statistics, in the 1960s, the kilns produced about 3 million pieces each year. By the 1970s, it had decreased to about 1.8 million pieces, specifically: Cong Minh kiln 450,242 pieces, Hiep Nghia kiln 410,200, My Loi kiln 340,420, Minh Thanh kiln 320,680 and Hiep Thanh kiln 270,820. This number certainly could not meet the needs of households.

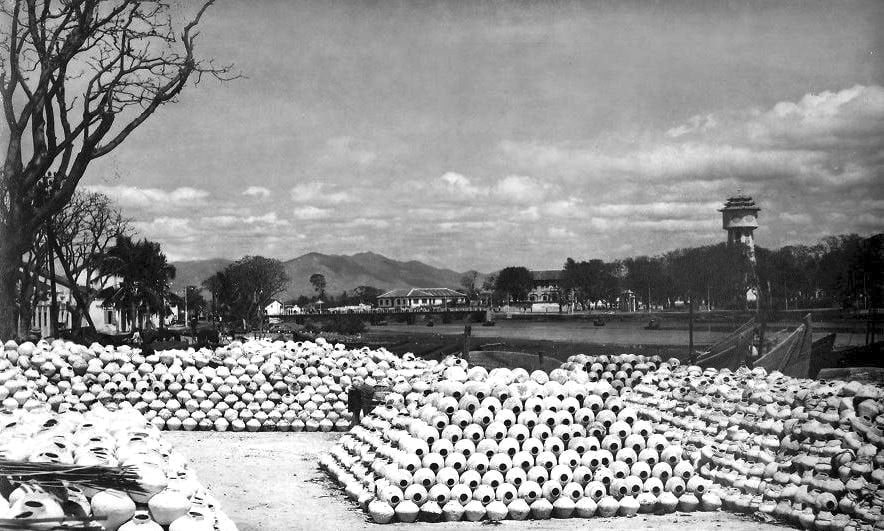

Going back in time to the 1930s, we see that the amount of fish sauce that Binh Thuan people produced was really “huge” – 50 million liters in 1928. Therefore, it took 13 million jars to handle it. The solution was to import more jars from Binh Duong, Cho Lon and even Phu Yen as in the case of Lien Thanh Company.

4. Volume variation

Looking at the remaining jars today, we see that they have a much smaller capacity than during the French colonial period. Guillerm in “L'industrie du Nuoc-Mam en Indochine” said: Before 1931, the jars contained 7 liters of fish sauce; but after that, the capacity was almost uniform from 3 liters to 3 liters 25. Later, author Le Van Lua (1973) also gave specific data on the fluctuations in the capacity of each jar of fish sauce: 1951-1954: 2 liters 7, 1955-1956: 2 liters 9, 1957-1958: 3 liters, 1959-1960: 3 liters 3; from 1961 to before 1975 it was 3 and a half liters. Therefore, some of the jar artifacts that we see today have many sizes.

5. Manufacturing process

Before 1975, the kilns in Phan Thiet usually had 3 sizes: The first-class kiln could hold up to 4,000 pieces; the second-class kiln could hold 3,000 pieces and the third-class kiln could hold about 2,000 pieces. The kilns were built in a long and long shape, high above and low below, different from the usual ceramic kilns for producing bricks and tiles. To build a kiln cost at least 300,000 VND (about 6 taels of gold) and 100 workers.

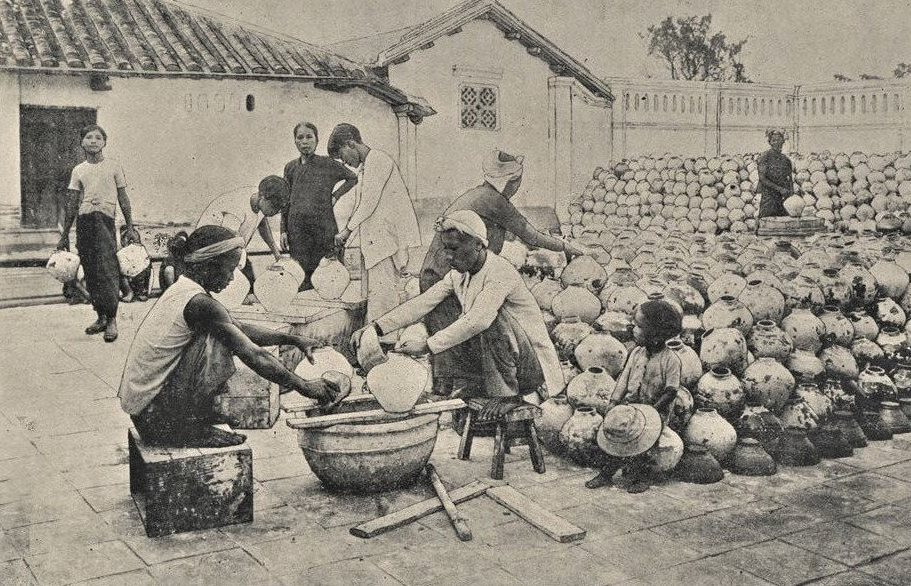

The main raw material for making tin is clay mined from the fields (the best is from the area with termite mounds). The soil is brought to the kiln and soaked in a cellar containing water to soften. In addition to the clay, the kiln workers also mix in white sand and red gravel; pound it until smooth and then put it into a mold to shape it. The shaped tin is dipped in glaze; the glaze for dipping tin is a mixture of young mud (taken from the river flowing through Ong Nhieu bridge (also known as bridge 40) and clear ash water. After being glazed, the tin is dried in the sun for 48 hours, then put into the kiln to be fired.

When the tin is taken out of the kiln, the worker uses a rag or loofah or coconut fiber to clean the inside. Then, use cement diluted with water to brush the outside of the tin, let it dry, and then hand it over to the worker for a final inspection before leaving the factory. This step is called "chi" tin. By immersing the tin in a bucket of cold water to see if there are any cracks or holes; if there are any, lightly repair it by using a mixture of cement, lime powder and fish oil to fill it, heavily discard it. After chipping, the tin must be painted with 2 more layers of lime water (mixed with cement) to complete the product.

6. Advantages of static electricity

At a time when the fish sauce industry had not yet applied modern machinery for bottling, using a wide-mouthed jar was very convenient for decanting. After pouring fish sauce into the jar, workers would use a lid (also made of ceramic, called a vum/dum lid) to cover the mouth, then use a type of mortar consisting of: lime, sand and molasses (or cement) to seal it (also called khanh). While the mortar was still wet, stick the label on, wait for it to dry and tie the handle with a palm leaf.

During the French colonial period, according to regulations, fish sauce jars had to have a clear label in three languages: Vietnamese, French, and Chinese to know where the fish sauce was made.

Due to the shape of the two ends and the bulging belly (Phu Quoc fish sauce pots have a slim belly), they can be stacked in many layers, 2-3 meters high, whether the pots are empty or contain fish sauce inside. Because the top layer of pots is located right in the gap between the 4 pots below, it forms a block, so it can be transported in large quantities over long distances without fear of breaking. Moreover, pots do not need wooden crates, straw bags, rice husk covers, sawdust... to protect them like bottles. Compared to using bottles, fish sauce stored in pots is cheaper. For example, in the 1960s, each pot of fish sauce (3.5 liters) cost 5 dong; meanwhile, 1 liter of fish sauce stored in a bottle cost 6.05 dong.

Moreover, the tin is very suitable for fish sauce. Fish sauce left in the tin for a long time will ferment again, thus increasing its quality value. Therefore, Phan Thiet people compare the tin containing fish sauce to good wine buried underground for a long time.

The craft of making tin has contributed to solving the jobs for many people, from woodcutters to workers specializing in making tin such as: Firemen, tin shapers, tin workers, skin sweepers and tin dryers... And within the framework of the tin craft, we must also mention lime miners to provide lime for tin skin, and the craft of making sail covers. In addition, we must also mention those who specialize in making sail cushions and making tin handles from palm leaves in the localities near Phan Thiet.

Currently, fish sauce sold in retail in Phan Thiet is packaged in a variety of packaging, with volumes ranging from 27 ml - 1,000 ml. These are PET plastic bottles, glass bottles and even ceramic tins such as the brand "Tin fish sauce - 300 year old formula" of Seagull Company Limited (Ancient Fishing Village Fish Sauce Museum). Although the tin kilns have "turned off the fire" for a long time, the image of the tin and the flavor of the old tin fish sauce are still the memories not only of Binh Thuan people but also of customers from the South to the North.

Source

Comment (0)