Thailand in trouble

In early July, Chinese electric car maker BYD celebrated the opening of its first factory in Southeast Asia, located in Rayong, south of Bangkok, with a capacity of 150,000 vehicles/year. The event attracted media attention not only in Thailand but also throughout Southeast Asia.

A new world record for the speed of building a factory by an automobile company has been set. If previously, a car company set a miracle in the world automobile industry by completing the construction of a factory within 21 months, BYD broke the record by building a factory in Thailand in just 16 months.

The launch of the BYD Thailand plant was marked with great fanfare, with the appearance of the BYD Dolphin hatchback, which was later transferred to a charity under the patronage of the Thai royal family.

Attracting BYD to invest in Thailand has been widely praised, especially for its long-term vision for the industry. Thailand has set a target of 30% of cars produced in the country being electric by 2030.

On the other hand, less reported events are stirring up public opinion in Thailand. Just weeks before BYD opened its factory, two Japanese auto giants, Suzuki Motor and Subaru, announced they would close their factories in the country.

At the end of May, according to Thaiautonews, Subaru said it would end car production in Thailand in December this year, after having stopped production in Malaysia.

In early June, Japanese automaker Suzuki also announced that it would close its factory in Thailand by the end of 2025 after 14 years of establishment.

Both factories have struggled with sluggish sales amid a surge in Chinese EVs. Subaru and Suzuki sell just a few thousand units a year, while BYD is expected to sell 30,650 EVs in 2023, despite not having a factory in Thailand yet.

The announcement of the Japanese automakers' closure is a bad sign for Thailand's manufacturing industry, which contributes about 25% of the country's GDP.

The retreat by Japanese automakers also reflects the struggles of many businesses in Southeast Asia’s second-largest economy . Thailand recorded 2,000 factory closures in 2023, leaving many workers unemployed.

The manufacturing sector's woes have hampered Prime Minister Srettha Thavisin, who took power last year, in fulfilling his promise to raise average annual GDP growth to 5% during his four-year term, up from 1.73% over the past decade.

Sharing with the media, Chairman of the Planning Committee of the National Economic and Social Development Council of Thailand Supavud Saicheua said that Thailand's decades-long manufacturing-based economic model has been broken.

World in turmoil?

According to Supavud Saicheua, the Chinese are pushing exports. Cheap imports from China are really causing trouble for Thailand. The country has to change and focus on producing products that China does not export, and strengthening its agricultural sector. There is no other way.

Statistics show that the number of factories closing in Thailand within a year, up to mid-2024, increased by 40% compared to the same period. As a result, job losses increased by 80%, with 51,500 workers unemployed.

Not only in Thailand, the fact that large Chinese corporations set up factories and bases in many countries also threatens the production in many countries. Many products can be in trouble when competing with Chinese goods.

With the factory located in Thailand, BYD branded electric cars can flood not only Thailand but also Southeast Asian countries.

In 2023, with cheap prices and 0% import tax (according to the provisions of the ASEAN Trade in Goods Agreement since the beginning of 2018), Thai cars have flooded into Vietnam. Cars originating from this country account for nearly half of the total import turnover of completely built-up cars in our country, with a total value of more than 1.14 billion USD.

Despite being subject to import taxes of 47-70% depending on the type, cars manufactured in China still rank third in terms of quantity and value imported into Vietnam.

Recently, BYD officially entered the domestic market. In the near future, the low-cost electric car company may increase sales from Thailand to Vietnam.

BYD is currently the world's largest electric car maker, with sales of 3 million units in 2023. The group is boosting exports and establishing bases in many countries.

In early July, BYD reached an agreement with the Turkish government to build a $1 billion factory with a capacity of 150,000 vehicles. The factory is expected to go into production by the end of 2026.

Since July 4, the European Commission (EC) has increased tariffs on Chinese electric vehicles (such as BYD, Geely, SAIC) from 17.4% to 38.1% to protect the industry of member states. Other Chinese carmakers are subject to tariffs of more than 20%. According to the EC, a recent investigation has shown that the Chinese electric vehicle value chain benefits from "unfair subsidies", harming EU competitors.

By agreeing with Türkiye, BYD has access to European markets thanks to the Türkiye-EU Customs Union agreement, which allows goods to move freely between the EU and Türkiye without import duties or quantity restrictions.

BYD also has factories in Uzbekistan, Brazil, and Hungary. The Chinese electric car maker has decided to build a $1.3 billion factory (capacity of 150,000 vehicles) in Indonesia in 2024.

According to Nikkei Asia, many Chinese electric vehicle manufacturers, including BYD, are rushing to move to Mexico and Brazil to make it easier to export to the US after Washington increased tariffs fourfold to 100% on electric vehicles imported from China.

Source: https://vietnamnet.vn/ong-lon-xe-dien-trung-quoc-banh-truong-thai-lan-giat-minh-the-gioi-dieu-dung-2302586.html

![[Photo] Prime Minister Pham Minh Chinh meets with Hungarian President Sulyok Tamas](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/29/dbcaa73e92ea4448a03fe1d0de6d68e8)

![[Photo] Vietnamese and Hungarian leaders attend the opening of the exhibition by photographer Bozoky Dezso](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/29/94d8ceca5db14af3bf31285551ae4bb3)

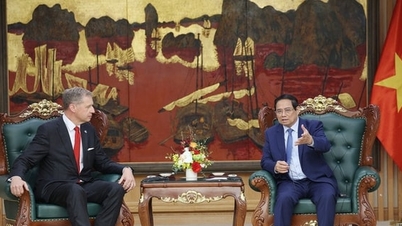

![[Photo] Prime Minister Pham Minh Chinh receives a bipartisan delegation of US House of Representatives](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/5/28/468e61546b664d3f98dc75f6a3c2c880)

Comment (0)