Sharing on August 2, Associate Professor Dr. Ngo Duy Thin, representative of the research team developing customized implant technology using PEEK biomedical material, said that in cases of skull bone defects, traditional treatment methods still have many limitations.

Specifically, autologous skull grafting has the risk of bone loss, collapse, and a complication rate as high as 37%. Manually grafting skulls with titanium mesh in the operating room has low accuracy and aesthetics, and can easily cause interference during magnetic resonance imaging (MRI).

Associate Professor, Dr. Ngo Duy Thin, representative of the research team (Photo: LG).

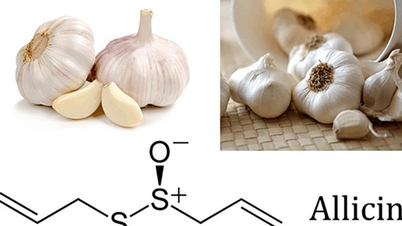

Therefore, bringing PEEK material to Vietnam and successfully applying it with 3D printing technology to create skull grafts is a great success of domestic scientists .

Sharing the same opinion, Dr. Nguyen Van Trung, former Head of Neurosurgery Department, Hai Duong General Hospital, added that after surgery to reconstruct the skull structure with autologous skull bone grafts, many people had graft resorption.

Another commonly used material is titanium, which is soft but does not solve the problem of shaping the skull, and its hardness is not as expected. In addition, cases of unrepaired forehead damage lead to deformation, poor aesthetics, and reduced patient confidence.

Dr. Nguyen Minh Loi, Director of the Department of Infrastructure and Medical Equipment ( Ministry of Health ) also shared the difficulties, hardships as well as the determination of the production unit, from the time of submitting the application to being licensed by the Ministry of Health (July 4) took up to 5 years. This is a very long journey.

In recent times, the Ministry of Health has made many reforms and innovations in medical equipment management. In the early days of 2020-2021, there were nearly 17,000 unlicensed C and D files, but now the authorities have processed 97% of them, leaving only about 1,000 files that have been read but not yet licensed due to not meeting the requirements.

Dr. Nguyen Minh Loi, Director of the Department of Infrastructure and Medical Equipment - Ministry of Health (Photo: LG).

“The health sector also gives special priority to domestically produced products, prioritizing licensing. At the same time, it is studying and perfecting policies with the two latest resolutions on how to develop the domestic medical equipment manufacturing market.

We are also working with health insurance agencies so that products like 3D-printed PEEK skull implants will soon be covered by health insurance, maybe not fully but partially, so that people can access them soon,” said Dr. Loi.

In the coming time, he hopes that domestic manufacturing enterprises will contribute ideas to perfect the policy system, helping the domestic medical equipment manufacturing market to develop further.

The product is 3D printed according to each patient's CT image data, ensuring accurate size and shape, and can be sterilized and ready for use in surgery.

To date, nearly 200 patients have had this device successfully implanted. The longest case was 7 years.

Source: https://dantri.com.vn/suc-khoe/ung-dung-cong-nghe-in-3d-sua-chua-khuyet-hong-xuong-so-20250802161509898.htm

![[Photo] General Secretary To Lam receives Governor of Kanagawa Province (Japan) Kuroiwa Yuji](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/11/15/1763204231089_a1-bnd-7718-5559-jpg.webp)

![[Photo] Exciting contest of skillful red fruit picking and creativity from Son La coffee beans](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/11/15/1763201832979_ndo_bl_3-jpg.webp)

![[Photo] Panorama of the 2025 Community Action Awards Final Round](https://vphoto.vietnam.vn/thumb/1200x675/vietnam/resource/IMAGE/2025/11/15/1763206932975_chi-7868-jpg.webp)

Comment (0)