We visited the ship parts manufacturing workshop of veteran Nguyen The Kien, Director of Nam Dinh Waterway Equipment and Supplies Company, in Tran Quang Khai Ward (Nam Dinh City) on an early spring day of the new year. From inside the workshop, the sound of engines of various machines rang out loudly and rapidly, signaling an urgent and bustling work pace. In the past 3 years, due to the impact of the COVID-19 pandemic and the world situation, the mechanical manufacturing industry in general has encountered difficulties. However, under the "steering" of Mr. Kien, the company still has "regular" orders, stable production, and high revenue.

|

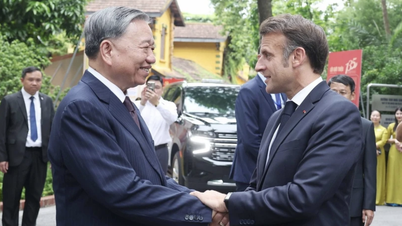

| Mr. Nguyen The Kien (right), Director of Nam Dinh Waterway Equipment and Materials Company, Tran Quang Khai Ward (Nam Dinh City) is an example of a former soldier who is good at business . |

After 4 years of service in the Information Command, in 1989, Mr. Kien was discharged from the army and returned to his hometown. Returning to Nam Dinh city, he applied to work at the City Fuel Materials Company. However, after 3 years, the company was dissolved, and Mr. Kien "turned" to selling grease to ships at Nam Dinh port. "This was also the "fate" that brought me to the profession of manufacturing ship spare parts later. Thanks to the grease trade, I had the opportunity to learn about the maritime industry, ships, spare parts, and equipment for seagoing ships. After a period of research, I realized that this was not only a business opportunity but also helped me satisfy my passion for mechanics, manufacturing mechanical products that I was passionate about," Mr. Kien shared about his "fate" in the profession. Initially, due to lack of experience, he could not produce ship spare parts and had to start by buying and selling used goods. He bought old ship equipment such as winches, anchors, chains, pumps, valves, etc. to repair and install for ship owners in need. After a period of buying and selling spare parts, Mr. Kien researched and came up with the idea of production. To be able to produce spare parts, he learned the trade on one hand and researched drawings of various types of machinery spare parts for the maritime industry on the internet. “To be able to read and understand drawings and draw on the computer, I had to learn AutoCAD. At that time, I was almost 50 years old, not an age that is “easy to learn” or “easy to get used to” with computers. But I was determined to learn it to serve my future production and business work,” Mr. Kien added.

After completing the AutoCAD program, Mr. Kien decided to open a workshop. Although it was called a workshop, at first his ship parts manufacturing facility was very "modest", with only enough space for 2-3 workers. However, Mr. Kien always encouraged himself that "all beginnings are hard", difficulties will pass, when there is enough potential, he will expand the scale of production. Not in vain for those who are diligent, in 1996, when his ship parts manufacturing workshop was opened, Mr. Kien immediately received large orders from ship owners. The market highly appreciated the products of winch decks, anchors, steering systems, valve pumps, doors for newly built and repaired ships... of Mr. Kien's workshop because of their durable quality, reasonable price, functionality, good service quality... "Good news travels fast", customers trust and come to the workshop more and more. Nearly 11 years after opening the factory, by 2007, Mr. Kien had accumulated some capital to expand the production scale, established Nam Dinh Waterway Equipment and Materials Company, realizing the initial dream with a 1,500m2 factory, many types of modern machinery worth billions of dong such as: lathes, drills, planers, milling machines... The company's products have "covered" most of the northern provinces and cities, including provinces and cities with strong consumption such as: Hai Phong, Quang Ninh, Thanh Hoa, Thai Binh...

In Mr. Kien's production work, things have not always been smooth. In the past 3 years, due to the impact of the COVID-19 epidemic, like many mechanical manufacturing facilities in the province, Mr. Kien's company has been severely affected. "When the epidemic broke out, ships could not travel, so we had no new orders. To maintain production, I had to have long-term plans and make appropriate adjustments," said Mr. Kien. Accordingly, on the one hand, he let workers continue to complete old orders, on the other hand, he tried to ensure wages to retain workers. In addition, he always ensured the implementation of the "prerequisite" factor of product quality and reasonable price. Mr. Kien's "efforts to overcome difficulties" and appropriate business orientation have helped the company gradually overcome difficult times and stabilize production and business. Every year, after deducting expenses, he earns billions of dong/year, creating regular jobs for 12 workers with a salary of 8-10 million dong/person/month.

Not only is he a veteran who is good at business, Mr. Nguyen The Kien is also an enthusiastic member of the Association. Mr. Kien is currently the Vice Chairman of the Veterans Club, excellent production and business veterans of Tran Quang Khai ward. Before that, he was the Chairman of the Veterans Club, excellent production and business veterans of Nam Dinh city for 5 years. Club members regularly share and exchange production experiences; actively compete in production and business; connect with customers; accept children of veterans and former soldiers to learn a trade, creating stable jobs... Most of the members of the clubs are well-off and have stable incomes.

Dynamic, creative, daring to think and act in production and business, former soldier Nguyen The Kien is reaping the "sweet fruits" from his constant efforts. Sharing his plans for the near future, Mr. Kien hopes to receive more support and preferential loans from credit institutions and banks, thereby having the conditions and opportunities to buy modern machinery, expand production and business, and create more jobs for local workers. Leaving Mr. Kien's factory amidst the noise of cutting machines, milling machines, etc. operating at full capacity, we secretly hope that the plans of this passionate and dedicated veteran will soon become reality./.

Article and photos: Hoa Quyen

Source

Comment (0)